Method for separating out and purifying epoxypropane and methyl alcohol

A technology of propylene oxide and methanol, applied in chemical instruments and methods, preparation of organic compounds, water/sludge/sewage treatment, etc., can solve the problems of high operating pressure and temperature, achieve low production cost, simple production process, The effect of making full use of material energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

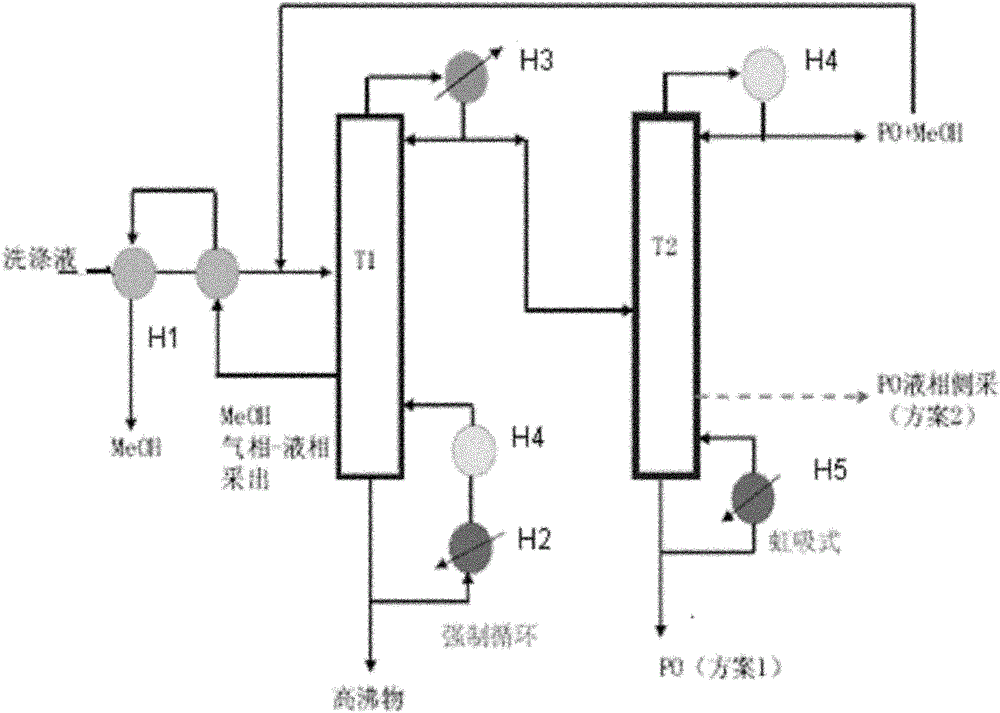

Method used

Image

Examples

Embodiment 1

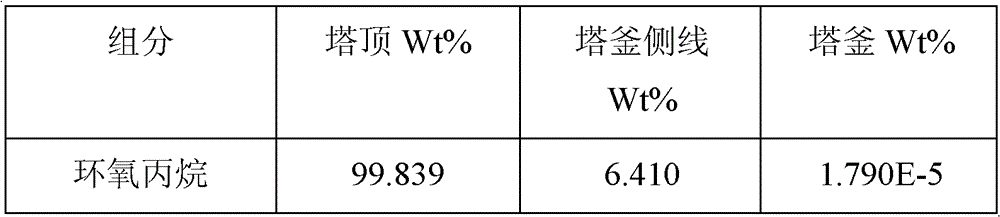

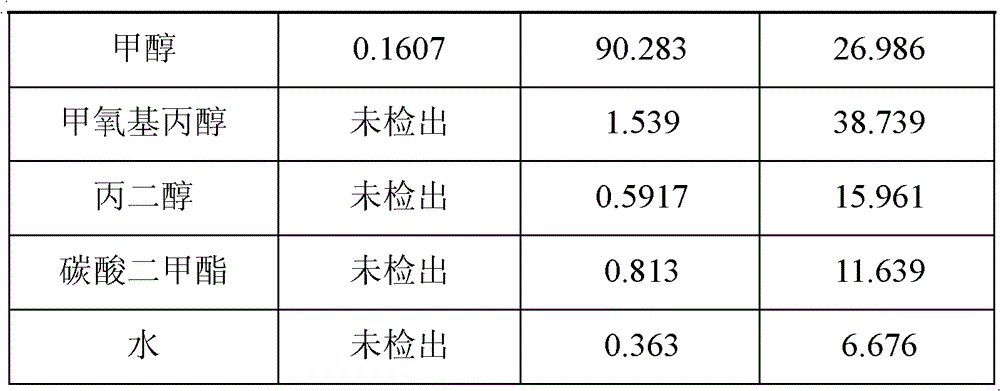

[0024]1) The washing mother liquor M1 shown in Table 1 is fed from the 23rd plate above the first rectification tower T1 tower still, and rectification is carried out with the first rectification tower T1, from the top of the first rectification tower Obtain the tower top material that contains propylene oxide crude product, obtain methyl alcohol at the 4th tray place above the tower still of the first rectifying tower T1 tower still side line;

[0025] Table 1, composition of washing mother liquor M1

[0026] components

[0027] The washing mother liquor shown in Table 1 is the mother liquor obtained by polymerization of propylene oxide and carbon dioxide under the condition of a rare earth three-way catalyst, coagulation washing with methanol, and solid-liquid separation;

[0028] In this rectification step, the operating pressure of the tower is 60kPa, the number of theoretical plates is 30, the temperature at the top of the tower is 21.0°C, the temperature at the...

Embodiment 2

[0039] 1) The washing mother liquor M2 shown in table 4 is fed from the 23rd tray above the first rectification tower T1 tower still, and rectification is carried out with this first rectification tower T1, from the top of the first rectification tower Obtain the tower top material that contains propylene oxide crude product, obtain methyl alcohol at the 6th tray place above the tower still of the first rectifying tower T1 tower still side line;

[0040] Table 4, Polypropylene carbonate production mother liquor M2 composition

[0041] components

[0042] Methanol

[0043] The washing mother liquor shown in Table 4 is the mother liquor obtained by polymerization of propylene oxide and carbon dioxide under the condition of a rare earth three-way catalyst, coagulation washing with methanol, and solid-liquid separation;

[0044] In this rectifying step, the operating pressure of the tower is 50KPa, the number of theoretical plates is 30, the temperature at the ...

Embodiment 3

[0055] 1) The washing mother liquor M2 shown in Table 7 is fed from the 13th tray above the first rectifying tower T1 tower still, and rectified with the first rectifying tower T1, and the Obtain the tower top material that contains propylene oxide crude product, obtain methanol at the 7th plate above the tower still of the first rectifying tower T1 tower still side line;

[0056] Table 7, composition of mother liquor M2 for producing polypropylene carbonate

[0057] components

[0058] The washing mother liquor shown in Table 7 is the mother liquor obtained by polymerization of propylene oxide and carbon dioxide under the condition of a rare earth three-way catalyst, coagulation washing with methanol, and solid-liquid separation;

[0059] In this rectifying step, the operating pressure of the tower is 30kPa, the number of theoretical plates is 25, the temperature at the top of the tower is 4.4°C, the temperature at the bottom of the tower is 50.0°C, and the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com