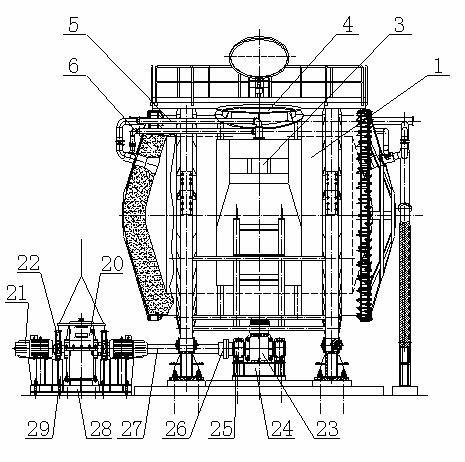

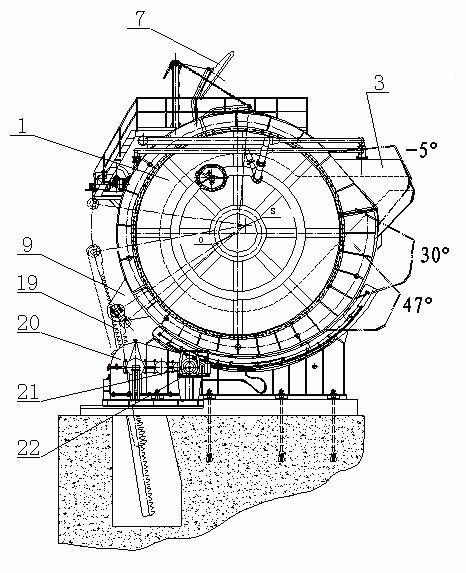

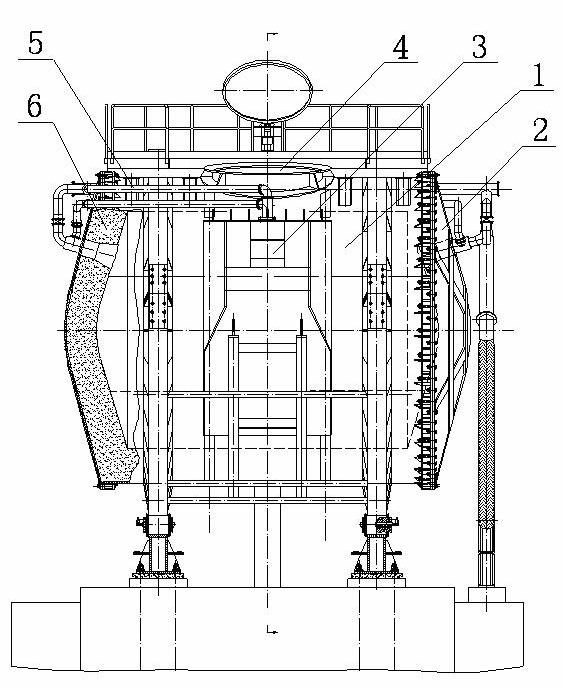

Hydraulic transmission type metal mixer

A technology of hydraulic transmission and iron mixing furnace, applied in the field of metallurgical equipment and hydraulic transmission type iron mixing furnace, can solve the problems of high maintenance cost, complex structure, short service life, etc., and achieve stable foundation force, simple equipment foundation, mechanical Low loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Taking the 900t mixed iron furnace as an example, the moment radius of the mixed iron furnace is 4.9m, which is determined by the external dimensions of the 900t mixed iron furnace. , calculate the stroke of hydraulic cylinder 11:

[0072]

[0073] Conservative design, get the stroke L=4300mm of hydraulic cylinder 11.

Embodiment 2

[0075] Taking the 900t mixed iron furnace as an example, the lifting force M=1700KN required for the tilting of the 900t mixed iron furnace can be obtained from Table 1, and the inner diameter of the hydraulic cylinder 11 can be obtained through the formula (2):

[0076]

[0077] Conservative design, take hydraulic cylinder 11 internal diameter d=500mm.

Embodiment 3

[0079] Taking the 600t mixed iron furnace as an example, the lifting force M=1000KN required for the tilting of the 600t mixed iron furnace can be obtained from Table 1, and the inner diameter of the hydraulic cylinder 11 can be obtained through the formula (2):

[0080]

[0081] Conservative design, get hydraulic cylinder 11 internal diameter d=380mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com