Method for preparing iron-based nanocrystalline material by mid-low-frequency magnetic pulse

An iron-based nanocrystal and magnetic pulse technology, applied in magnetic materials, magnetic objects, electrical components, etc., can solve the problems of complex process, long reaction time, annealing embrittlement of iron-based nanocrystalline materials, etc., to avoid alloy brittleness. effect of annealing and avoiding annealing embrittlement

Inactive Publication Date: 2011-06-15

NORTHEASTERN UNIV

View PDF3 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This process is complicated, the reaction time is long, and it is easy to cause annealing embrittlement of iron-based nanocrystalline materials.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

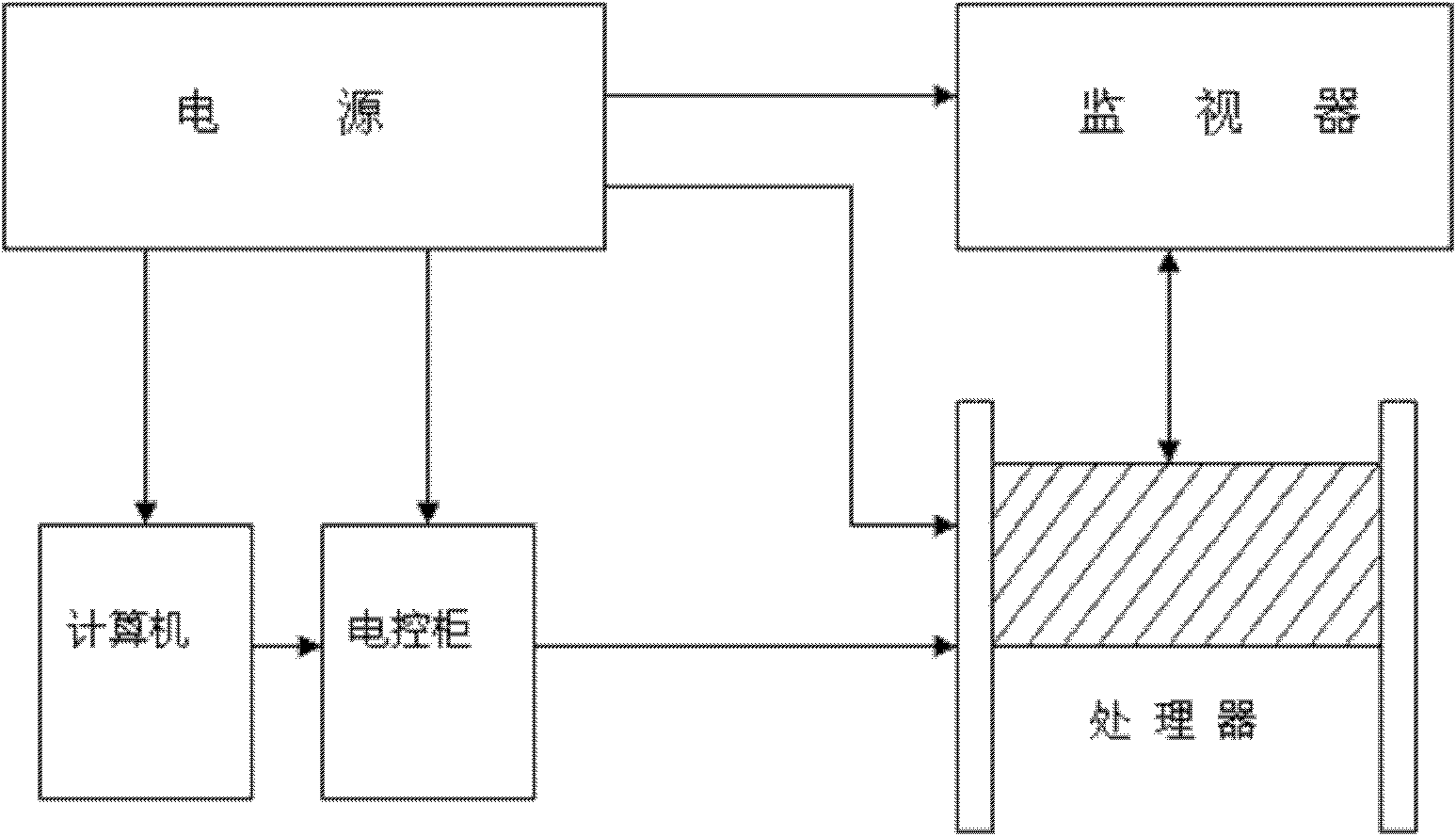

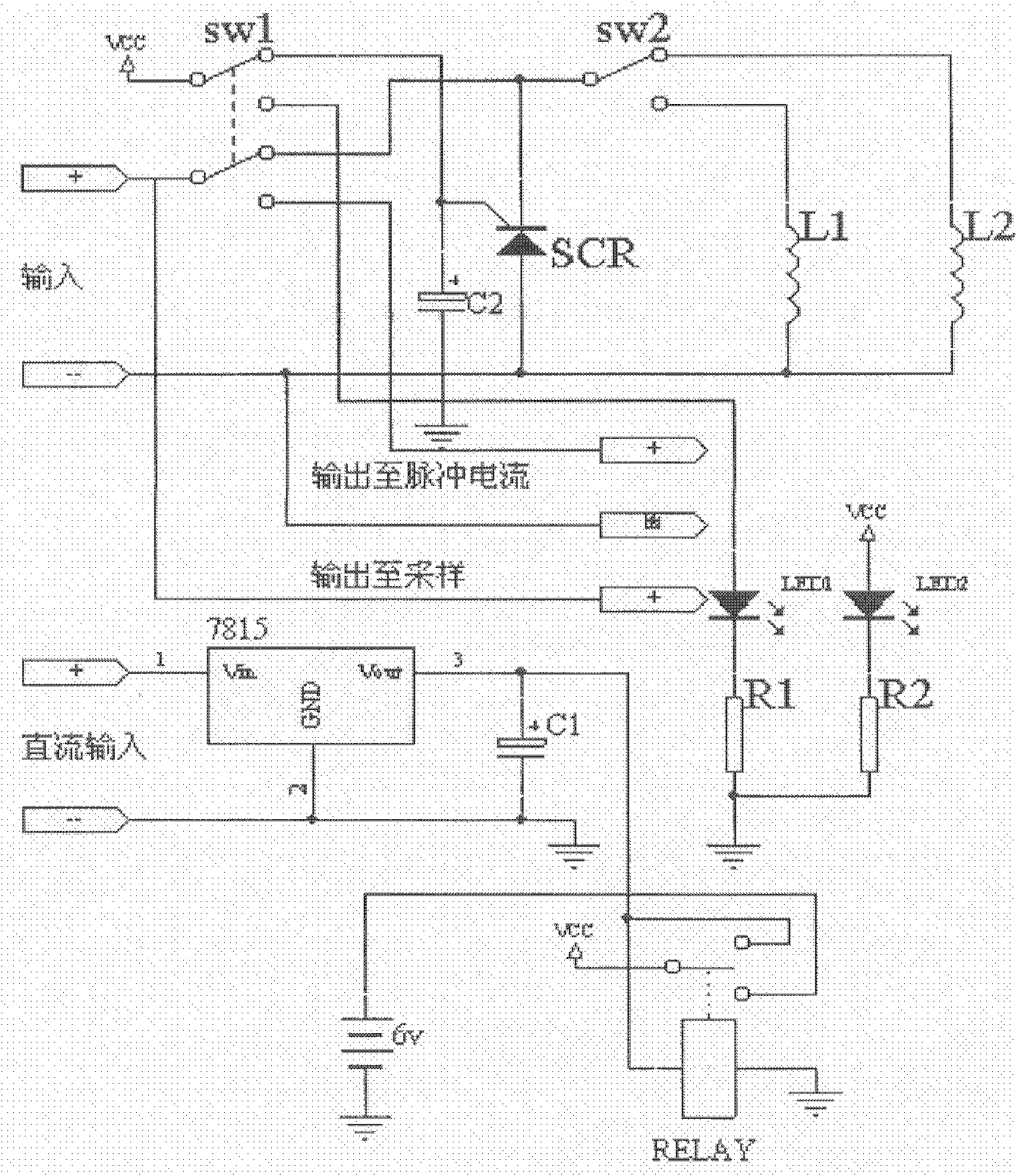

The invention relates to the technical field of the preparation of soft magnetic materials, in particular to a method for preparing an iron-based nanocrystalline material by a mid-low-frequency magnetic pulse. The method comprises the following steps: at a vacuum degree below 5*10<-3>Pa, smelting alloy materials into a mother alloy molten mass in a vacuum high-frequency furnace or arc furnace; then, at a vacuum degree of 2*10<-3>Pa, injecting the mother alloy molten mass into a vacuum single-roller molten mass rapid-cooling device under the protection of an argon gas atmosphere, and preparing the mother alloy into an amorphous thin strip, wherein the linear surface velocity of a cooling roller is 45-49m / s, the distance between a quartz nozzle and a copper roller is 0.5mm, the superheating temperature of the molten mass at the outlet of the nozzle is 50K; and finally, carrying out magnetic pulse treatment on the amorphous thin strip in a multi-function process control pulse magnetic field generator to obtain the amorphous nanocrystalline material, wherein the field intensity Hp of the magnetic pulse is 100-400Oe, the frequency f is 20-2000Hz, and the operation time tp is 5-10 minutes.

Description

A method for preparing iron-based nanocrystalline materials by medium and low frequency magnetic pulses technical field The invention relates to the technical field of preparation of soft magnetic materials, in particular to a method for preparing iron-based nanocrystalline materials through medium and low frequency magnetic pulses. Background technique The iron-based nanocrystalline material is a dual-phase nanoalloy in which the nanocrystals obtained after the nanocrystallization treatment of the iron-based amorphous are dispersed in the remaining amorphous matrix. It has good soft magnetic properties, that is, low coercive force and high saturation magnetization, and is widely used in power transformers, switching power supplies, sensitive sensors and other fields. In particular, the nano-alloy-HITPERM formed by FeCoHfBCu amorphous nanocrystallization has high high-temperature magnetic induction, low coercive force, and the working temperature can reach above 500 ° C. I...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C45/02H01F1/153

Inventor 晁月盛杜安邹壮辉张延辉

Owner NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com