Pressure transmission sealing coupler

A transmission sealing, pressure type technology, applied in couplings, rigid shaft couplings, mechanical equipment, etc., can solve the problems of structural vibration loose failure, shortened service life, stuck, etc., to achieve reciprocating stress dispersion, prolong the overall Longevity, effect of preventing dry friction

Inactive Publication Date: 2011-06-15

任宇

View PDF4 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, ordinary couplings usually have a limited degree of sealing. During rotation, they are prone to jamming and water leakage due to the penetration of foreign impurities, resulting in severe wear and tear of bearings, oil seals and other accessories, and they have to be replaced. If the sealing effect is to be ensured, many components must be added oil seal, but it is often not possible due to the limitation of installation space; in addition, if the coupling adopts pressure transmission, it will produce axial movement due to reciprocating axial stress, which will accelerate the damage of the bearing, and also It is easy to cause the structure to be shaken loose and fail

Therefore, traditional couplings cannot work in harsh environments full of particulate impurities such as sandstorms and mortar

In addition, although the traditional coupling has an input shaft interface and an output shaft interface, the design form of the output shaft interface is usually a notch mode, so if the output shaft needs to reciprocate, it is extremely easy to damage the notch and shorten the overall service life

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

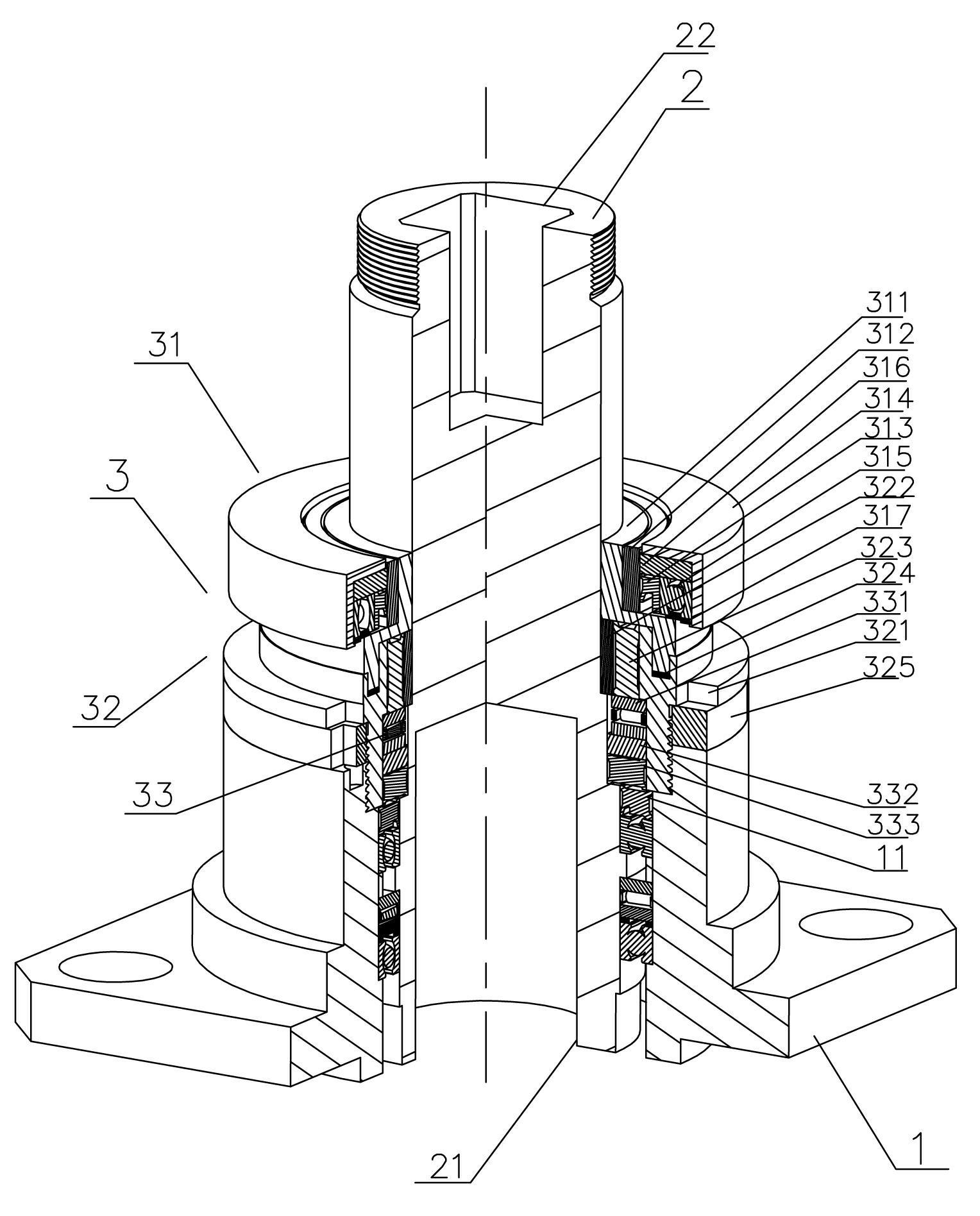

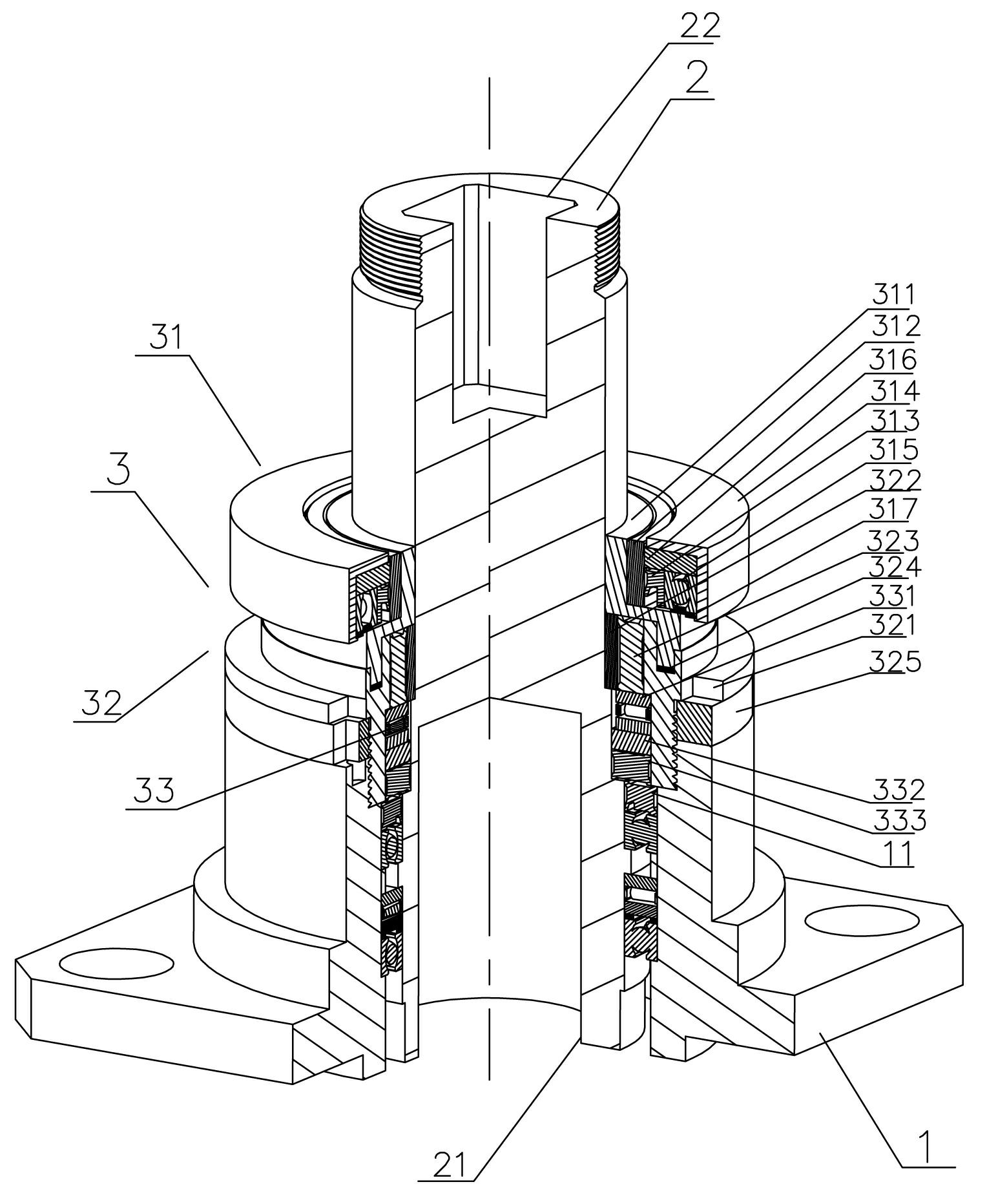

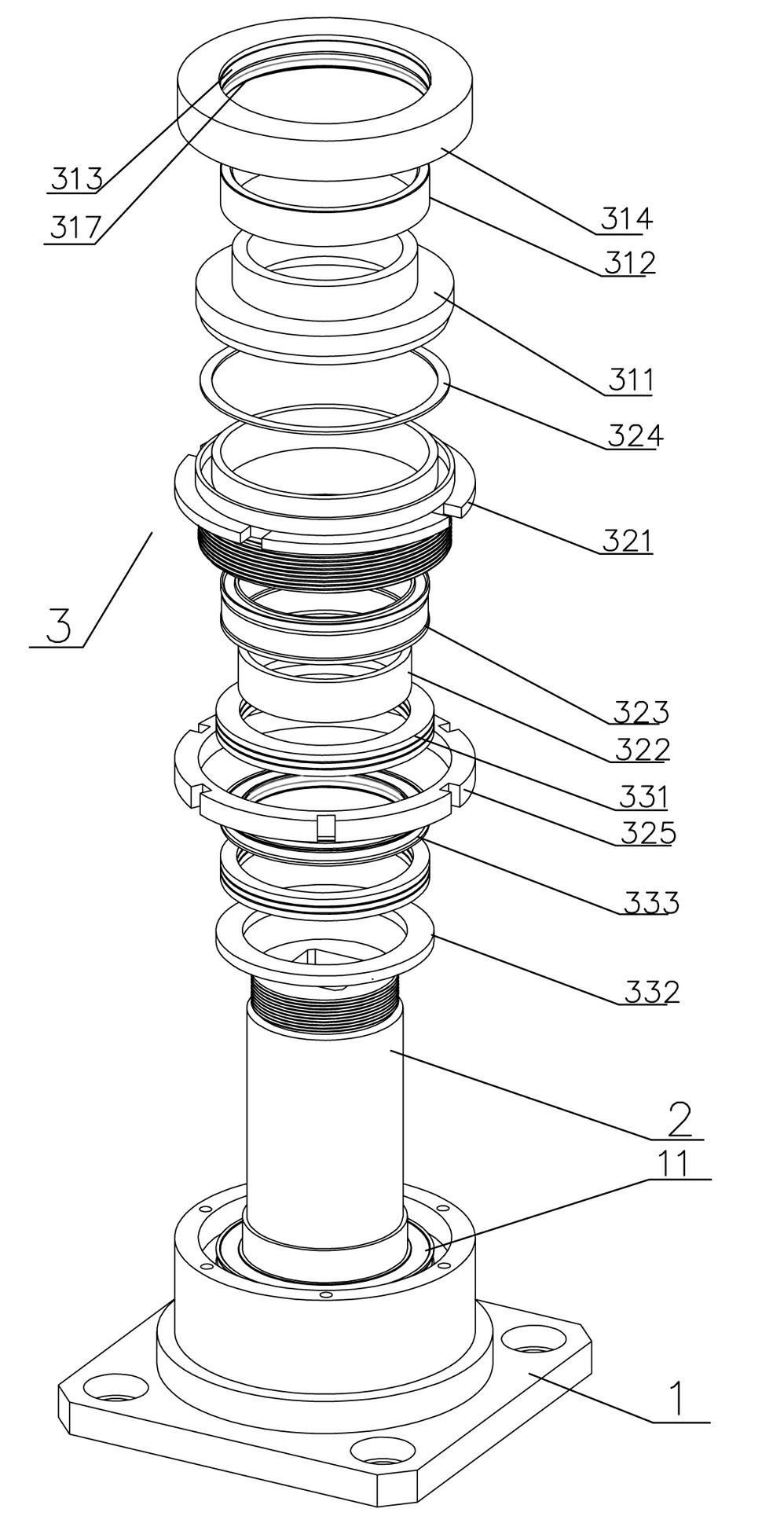

The invention discloses a pressure transmission sealing coupler. The coupler comprises a base in which an axial cavity is formed, wherein a rotating shaft which is provided with an input shaft interface and an output shaft interface passes through the axial cavity; the output shaft interface is positioned above the whole mechanism, and the input shaft interface is positioned below the whole mechanism; a bearing component and a base oil seal positioned above the bearing component are arranged between the rotating shaft and the base; and the base oil seal is provided with a waterproof pressure reducing sealing component which is compacted with the base oil seal, has an annular integral structure and is sleeved at the periphery of the rotating shaft and connected with the base. The waterproof pressure reducing sealing component is arranged, so that the bearing component in the coupler smoothly rotates and is prevented from being blocked, worn and burnt out even if the coupler works in an environment filled with particle impurities, and the service life of parts is prolonged; zero leakage is achieved, and the coupler has a good pressure reducing effect and a good axial movement prevention effect when working in a pressure transmission mode; and the coupler has a smart and compact structure and a wide application range, and can be applied to various shaft coupling occasions.

Description

Pressure type transmission seal coupling technical field The invention relates to a coupling, in particular to a pressure transmission coupling. Background technique In engineering production, the coupling is a common accessory that is widely used to connect the driving shaft and the driven shaft. It is generally provided with a driving shaft interface and a driven shaft interface, and then a bearing assembly and a sealing assembly are arranged between the two interfaces. However, ordinary couplings usually have a limited degree of sealing. During rotation, they are prone to jamming and water leakage due to the penetration of foreign impurities, resulting in severe wear and tear of bearings, oil seals and other accessories, and they have to be replaced. If the sealing effect is to be ensured, many components must be added oil seal, but it is often not possible due to the limitation of installation space; in addition, if the coupling adopts pressure transmission, it will p...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F16D1/02

Inventor 任宇

Owner 任宇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com