Instrument for detecting interlaminar cohesive shear strength of road surface after being soaked

A technology for shear strength and pavement interlayer, which is applied in the direction of instruments, measuring devices, and mechanical devices, can solve the problem of further improvement of the applicability of pavement interlayer shear strength testing instruments, and the research and development of shear strength Blank, low degree of automation of data acquisition and control systems, etc., to achieve the effect of easy promotion, simple structure and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

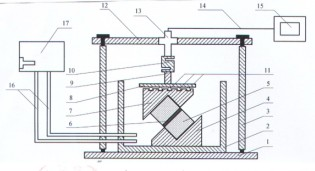

[0013] An instrument for testing the shear strength of interlayer bonded submerged in water, comprising a lower base 1, a water immersion tank 2, a bracket 12 is arranged on the water immersion tank 2, and a loading device 13 is arranged in the middle of the bracket 12, and the loading device 13 is located above the clamping mechanism The clamping mechanism is composed of the lower chuck 4 and the upper chuck 7. The clamping mechanism is used to fix the test piece 5. Between the clamping mechanism and the loading device 13, a bearing plate 8, a loading indenter 9 and a counteracting The force sensor 10 that the compression force on the test piece is detected in real time, the constant temperature tank 17 communicates with the immersion tank 2 through the heat preservation pipe 16, the control system 15 is connected with the loading device 13 through the connection line 14, and the control system 15 is to the signal detected by the sensor 10 Analytical processing and data acquis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com