Device and method for testing power cable fault

A power cable and testing device technology, which is applied in the field of power cable fault testing devices, achieves the effects of light weight, simple operation and safe testing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

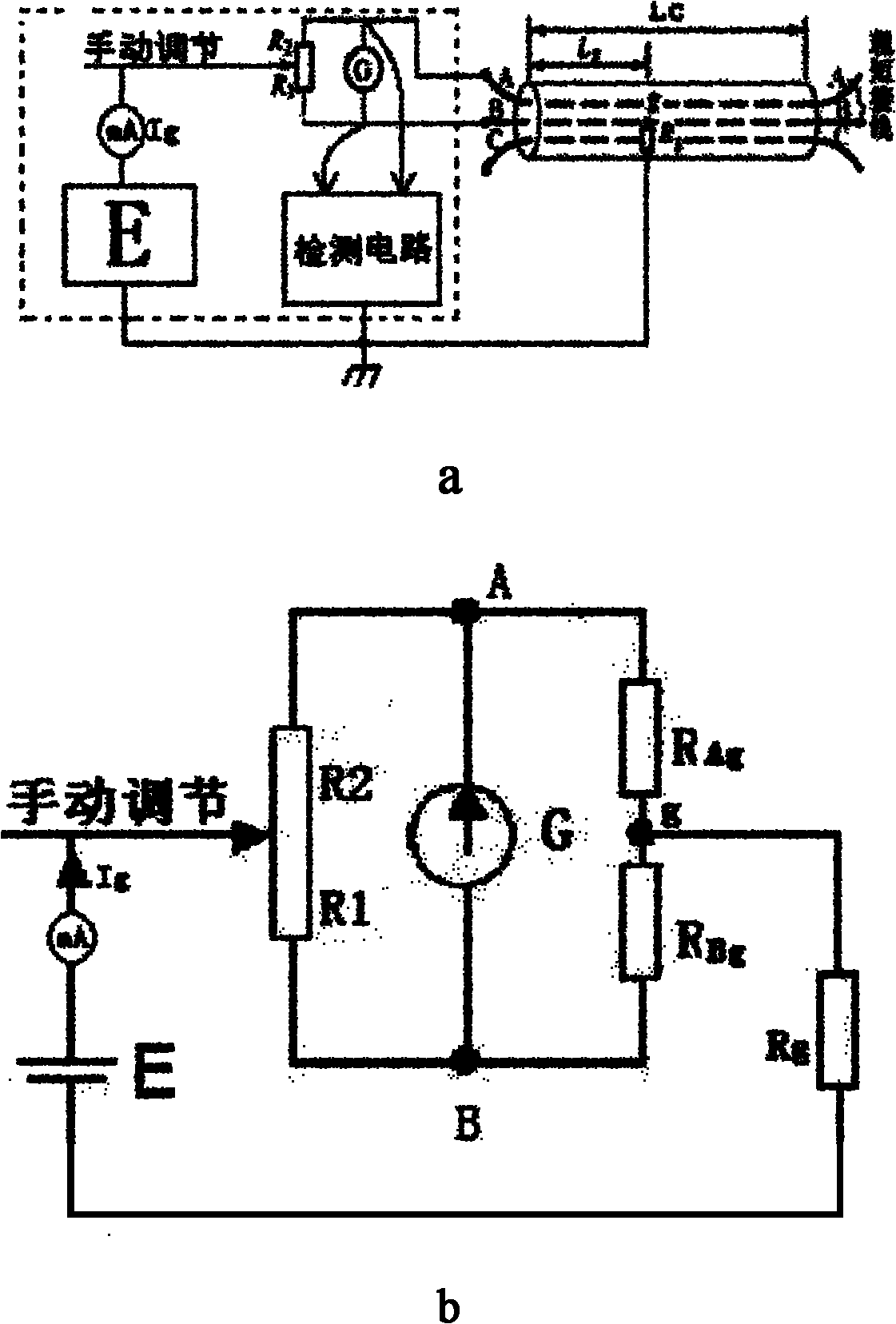

[0041] like figure 2 As shown in b, the bridge balance method. Include the following steps:

[0042] (1) Connect the two fixed ends of the potentiometer of the test device to any two phases A and B of the cable under test, one of which is a faulty phase, and connect the other ends of any two phases of the cable under test with thick and short wires to form a test A bridge circuit, the sliding end of the potentiometer is connected in series with a current sampling resistor RR to the output E of the high voltage part, and the fault test current acquisition end of the detection and control circuit is respectively connected to the two ends of the current sampling resistor RR; the detection and control circuit The control output end is connected to the sliding end of the potentiometer, and the detection signal end of the voltage across the test bridge of the detection and control circuit is separated from the high voltage part, and connected in parallel to the two fixed ends of t...

Embodiment 2

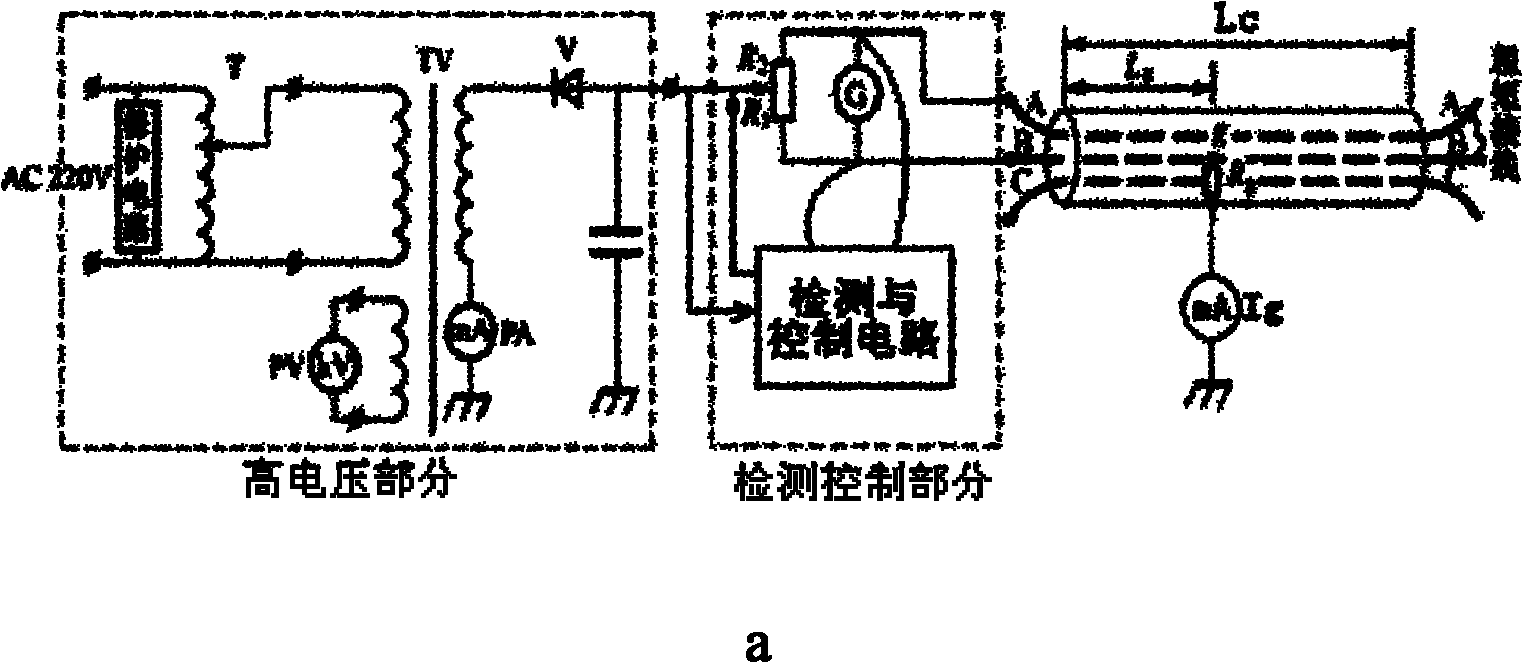

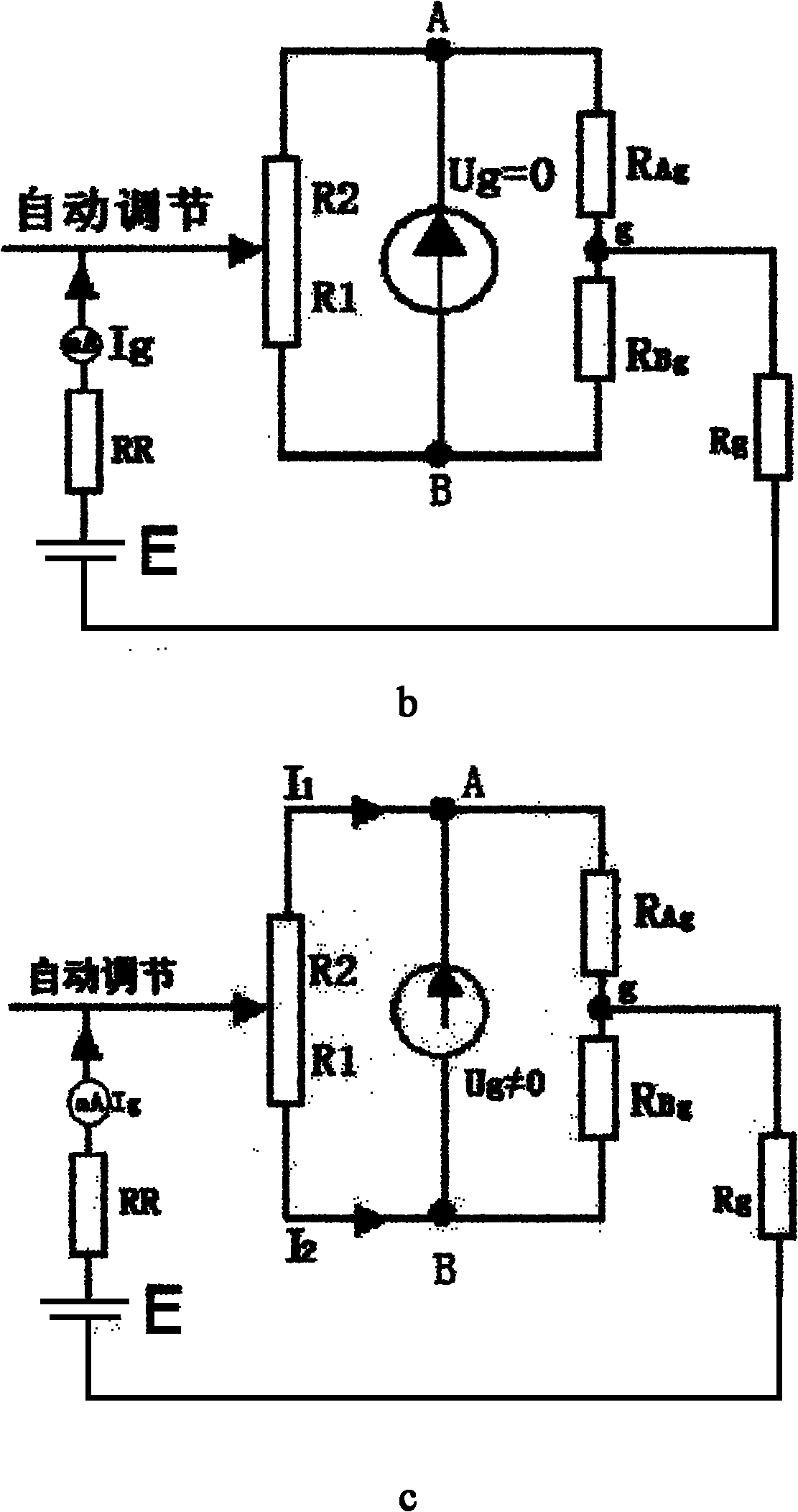

[0050] Bridge unbalance method. Include the following steps:

[0051] (1) Connect the two fixed ends of the potentiometer of the test device to any two phases of the tested cable, one of which is a faulty phase, and the other ends of any two phases of the tested cable are connected with thick and short wires to form a test bridge circuit , the sliding end of the potentiometer is connected in series with a current sampling resistor RR to the output E of the high voltage part, and the fault test current acquisition end of the detection and control circuit is respectively connected to the two ends of the current sampling resistor RR; the detection is connected to the control terminal of the control circuit To the sliding end of the potentiometer, the detection signal terminal of the voltage across the test bridge of the detection and control circuit is separated from the high voltage part, and connected in parallel to the two fixed ends of the potentiometer; then the potentiomete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com