Redundant and fault-tolerant safety instrument control system based on fieldbus and ARM (advanced RISC machines)

A safety instrumented, redundant fault-tolerant technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of slow system speed, misoperation, low safety integrity of a single subsystem, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

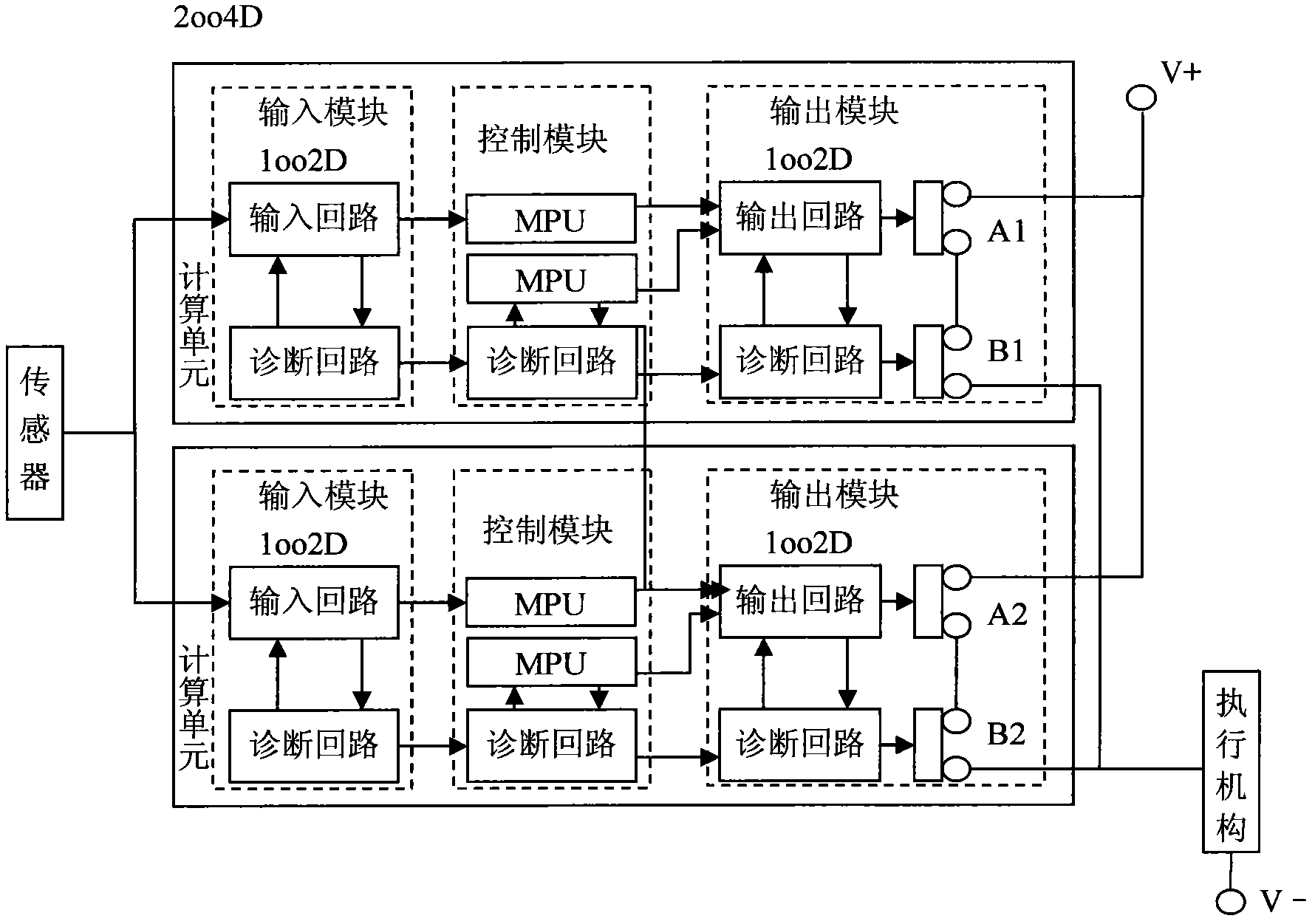

[0065] The safety instrumented device contains 4 independent signal processing channels, each channel includes an input module, a central processing module and an output module, each channel is redundant with each other, and the channels are completely electrically isolated; the 4-channel central processing units are independent , asynchronous operation, do not share their own input / output data, configure the same input and output subsystems, execute the same application program, process input data, and then create new output data; perform 4-channel correspondence through the output voting module Two out of four redundant fault-tolerant voting of the output signal, the voting result controls the final executive body;

[0066] Various safety instrument interlocking protection control projects (such as Figure 14 shown).

[0067] For the safety instrument device of the present invention, the overall system structure and work flow:

[0068] The input interface module transforms...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com