Asymptotic variational method-based method for simulating and optimizing composite material laminated plate

A composite material layer, asymptotic variational method technology, applied in the field of material mechanical property analysis, can solve the problems of inability to accurately predict stress distribution, low analysis efficiency, small calculation amount, etc. High and improved buckling critical load effect

Inactive Publication Date: 2011-06-15

CHONGQING UNIV

View PDF2 Cites 25 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Aiming at the problems of low analysis efficiency and poor precision in the prior art, especially the inability to accurately predict the stress distribution along the thickness direction, the purpose of the present invention is to provide a gradual Three-dimensional field simulation and optimization method of composite laminates based on near-variation method

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

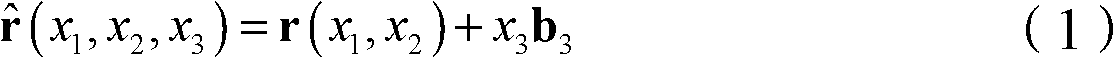

The invention relates to an asymptotic variational method-based method for simulating and optimizing a composite material laminated plate, which belongs to the field of analysis of material mechanics. The method specifically comprises the following steps of: constructing a three-dimensional plate energy equation represented by a one-dimensional generalized strain and warping function on the basisof a rotation tensor decomposition concept; strictly splitting the original three-dimensional problem analysis into nonlinear two-dimensional plate analysis and cross-section analysis along a thickness direction on the basis of an asymptotic variational method; asymptotically correcting an approximate energy functional of a reduced-order model to a second order by using the inherent small parameter of the plate and converting the approximate energy functional into the form of Reissner model for practical application through an equilibrium equation; accurately reconstructing a three-dimensional stress / strain / displacement field by using an obtained global response asymptotic correction warping function; and optimizing the composite material laminated plate by using an optimization strategy of bending and torsion rigidity coefficients obtained by maximization cross-section analysis. The method has high practicability and high generality, and the resolving speed and efficiency of this type of problems can be remarkably increased.

Description

A Simulation and Optimization Method for Composite Laminates Based on Asymptotic Variation Method technical field The invention belongs to the field of analysis of mechanical properties of materials, in particular to an optimization strategy capable of effectively simulating and accurately reconstructing the three-dimensional stress / strain / deformation fields of composite material laminates and maximizing the bending and torsion items of the stiffness matrix, and laminated composite materials An optimal design method in which the laying inclination angle is the design variable. Background technique In the past 20 years, advanced composite structures have been widely used in aerospace, machinery, civil engineering and other fields due to their high strength, high modulus, and designability. Many composite material structures are flat laminate structures whose thickness dimension is much smaller than that of the other two directions. The flexibility of composite material layu...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G06F17/50

Inventor 钟轶峰张亮亮牛建丰

Owner CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com