Process for producing transposition composite lead

A production process and combination wire technology, applied in cable/conductor manufacturing, conductor/cable insulation, transformer/inductor coil/winding/connection, etc., can solve the problems of burning transformers, increasing temperature rise, and reducing output, etc., to achieve easy-to-use effects

Inactive Publication Date: 2011-06-15

JIANGSU ZHONGRONG ELECTRIC

View PDF5 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

For example, the specification of semi-rigid self-adhesive transposition wire is 1.80×13.20, the number of wires is 59, the yield strength is 200---240N / m㎡, the transposition pitch is 110mm, and the insulation thickness of paper package is 0.75mm. The insulating paper is worn or bulged, and the production process is very difficult, which has considerable hidden dangers to product quality;

2) If the transposition wire is incompletely transposed or missed during the manufacturing process, or there is a deviation during winding, it is difficult to ensure the balance of the resistance and reactance of each winding, and a pressure difference will be generated, causing circulation loss ;

3) The transposition wire is wound into a cylindrical winding, and no transposition is required during the winding process, but if the additional loss of this winding is large, the loss of the transformer will increase, the noise will increase, and the temperature rise will increase , the output is reduced, the life of the transformer is reduced, and the transformer may be burned in severe cases

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Login to View More

Abstract

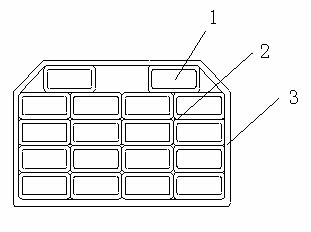

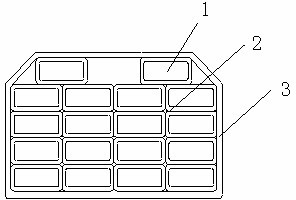

The invention discloses a process for producing a transposition composite lead, comprising the following steps of: enameling a group of one-step formed bare copper flat wires; transposing the finished enameled wires; insulating the transposed enameled wires via paper packing and arranging the enameled wires in parallel along a narrow edge; and uniformly wrapping insulating paper outside the paper packed enameled wires which are arranged in parallel along the narrow edge so as to obtain the transposition composite lead. In the invention, a coil winding process is easy for operation; and when the obtained transposition lead is applied to ultrahigh voltage transformers and extra-high voltage transformers, favorable impact voltage distribution is provided and the local discharging of coils is reduced.

Description

Production process of transposition combined wire technical field The invention relates to a transposition combined wire for transformer windings, in particular to a production process for a transposition combined wire used for large-capacity, high-voltage DC transformer windings. Background technique As the voltage and capacity of power grids and power stations increase, the voltage level and capacity of transformers also continue to increase. At the same time, winding damage accidents of large power transformers caused by external short circuits have also increased significantly, and the radial deformation of compressed windings is one of the typical forms of short circuit damage. Therefore, the market needs super large transformers with strong short circuit resistance. The combination wire came into being under this situation. The so-called transposition wire is to make multi-strand scattered and wound wires. Before winding the coil, they are transposed continuously a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01B13/00H01B13/06H01F27/28

Inventor 孙国平冯四平宋宝韫

Owner JIANGSU ZHONGRONG ELECTRIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com