Sealing device and condensing unit of evaporative cooling asynchronous motor stator as well as manufacturing methods thereof

A technology for asynchronous motors and evaporative cooling, applied in asynchronous induction motors, cooling/ventilation devices, electromechanical devices, etc., can solve problems such as stator winding looseness and shedding, large volume of stator sealing cavity, and high cost of asynchronous motors, and achieve reasonable distribution , Cooling effect is good, the effect of improving market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

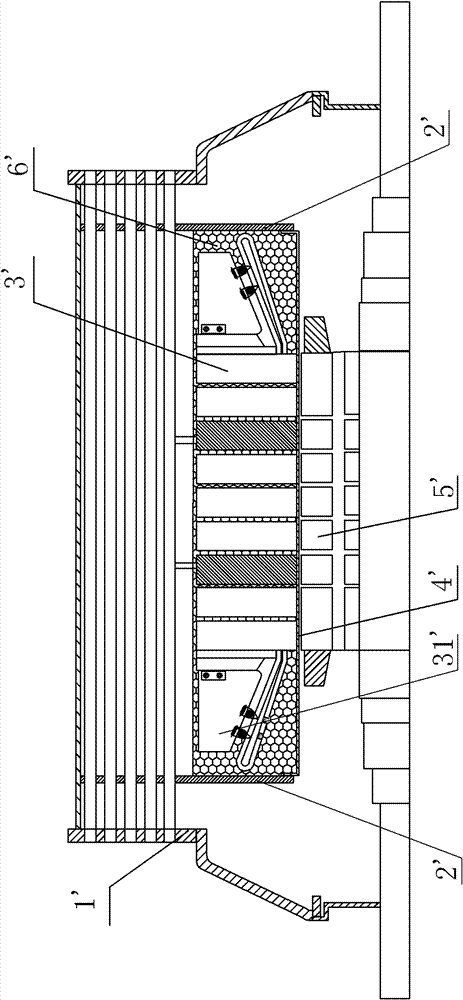

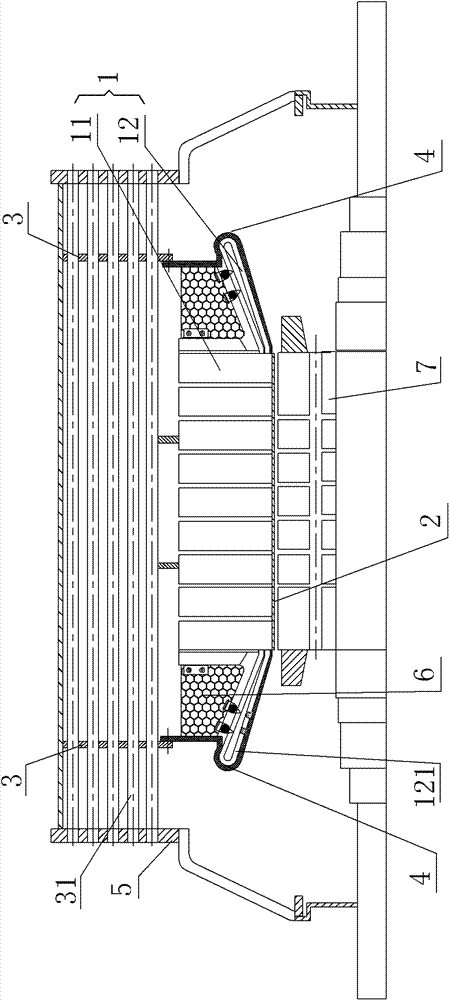

[0053] See figure 2 As shown, the embodiment of the present invention proposes an evaporative cooling condensing device for the stator of an asynchronous motor. The stator 1 includes a stator core 11 and a stator winding 12 connected to each other. The condensing device includes a sealing device for evaporative cooling of the stator of the asynchronous motor. The sealing device includes a sleeve 2, two cavity side walls 3 and two cavity connecting walls 4. The sleeve 2 is connected to the inner circular surface of the stator core 11; the outer edge of each cavity side wall 3 is hermetically connected to the casing 5 of the asynchronous motor; the outer end of each cavity connecting wall 4 is connected to the cavity side wall 3. The inner end is connected to the stator core 11 along the curved shape of the end 121 of the stator winding 12; wherein the sleeve 2, the cavity side wall 3, the cavity connecting wall 4 and the casing 5 constitute the stator sealing cavity body. The ...

Embodiment approach 2

[0066] The embodiment of the present invention provides a manufacturing method of a sealing device for the stator of an evaporative cooling asynchronous motor, which includes the steps:

[0067] A. The stator includes a stator core 11 and a stator winding 12 connected to each other. The sleeve 2 is glued on the inner surface of the stator core 11, and the sleeve 2 is located between the stator 1 and the rotor 7 of the asynchronous motor;

[0068] B. Connect the outer edges of the two cavity side walls 3 to the casing 5 of the asynchronous motor respectively, with the stator 1 located between the two cavity side walls 3;

[0069] C. Provide two cavity connecting walls 4 so that the outer end of each cavity connecting wall 4 is connected to the cavity side wall 3, and the inner end is connected to the stator core 11 along the curved shape of the end of the stator winding 12, so that The sleeve 2, the cavity side wall 3, the cavity connecting wall 4 and the casing 5 constitute a stator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com