Housing of electronic device

A technology for electronic devices and shells, which is applied in the direction of electric solid devices, circuits, electrical equipment casings/cabinets/drawers, etc., can solve the problems of low gloss and single structure, achieve elegant appearance, attractiveness, and increase use value and the effect of added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

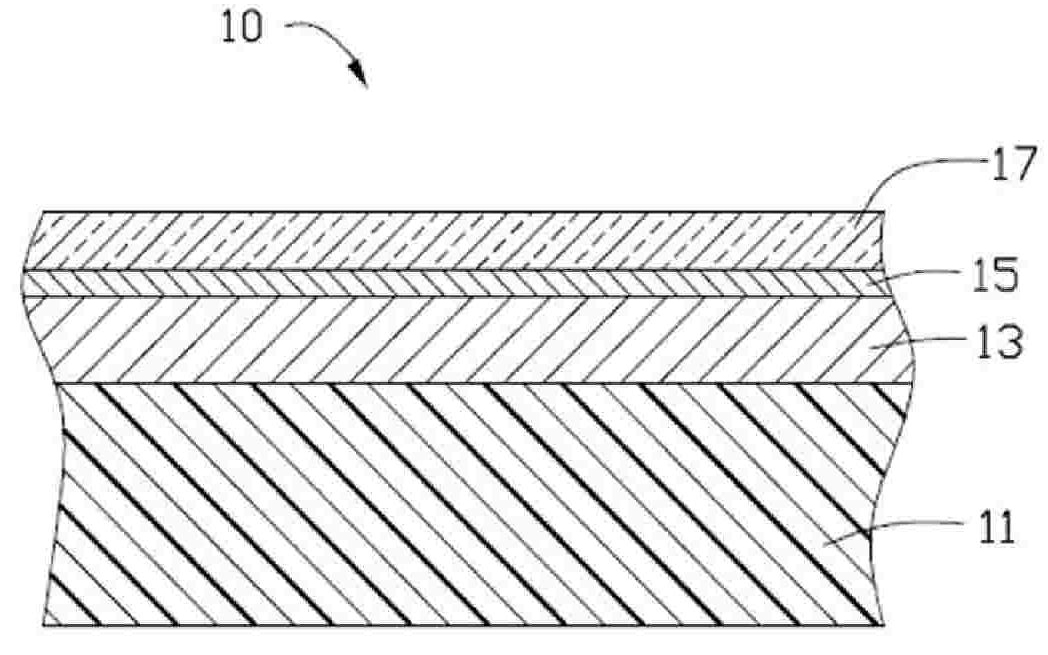

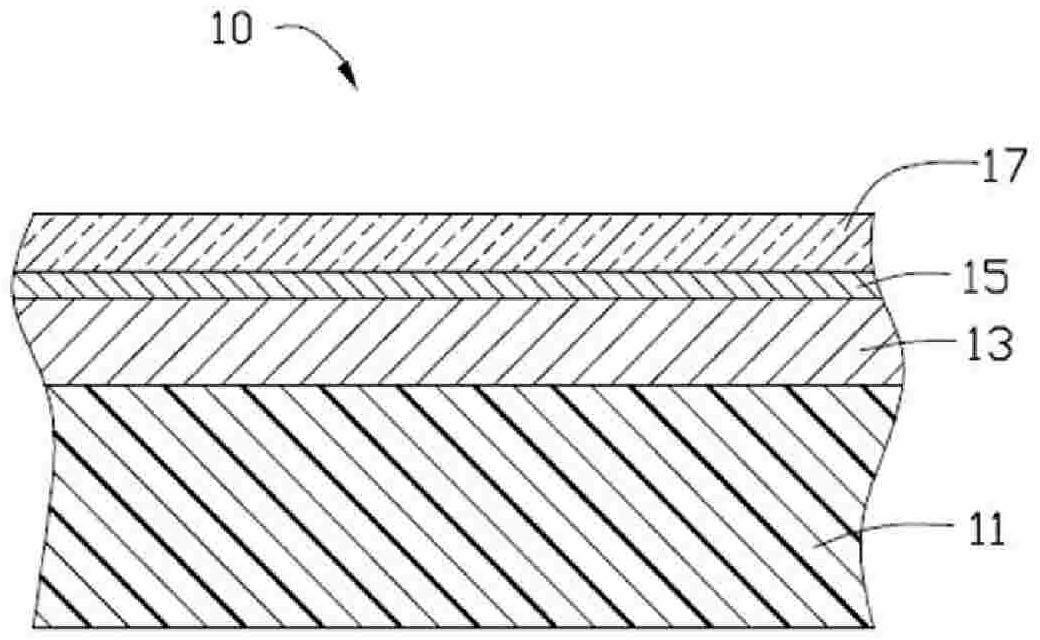

[0007] see figure 1 As shown, the electronic device casing 10 of a preferred embodiment of the present invention includes a substrate 11, a primer layer 13 formed on the substrate 11, a metal oxide film 15 bonded to the primer layer 13, and a metal oxide film 15 bonded to the metal oxide layer. The topcoat layer 17 on the object film 15.

[0008] The base 11 can be an opaque plastic base, which can be made by injection molding. Plastics for injection molding the matrix 11 can be selected from polypropylene (PP), polyamide (PA), polycarbonate (PC), polyethylene terephthalate (PET) and polymethyl methacrylate (PMMA) any of the. The substrate 11 can also be a ceramic substrate. The surface roughness of the substrate 11 is below 60nm. The substrate 11 can be white, black or other colorful colors, preferably white.

[0009] The primer layer 13 can be formed on the surface of the substrate 11 by spraying white, colored or colorless transparent acrylic resin paint. The primer l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com