Filtration method, method of purifying abrasive composition using the same, method of regenerating filter for use in filtration, and apparatus for regenerating filter

A filtration method and a technology of a regeneration device, which are applied in the directions of cleaning methods and appliances, fixed filter element filters, filtration and separation, etc., can solve problems such as effective and no provision of procedures, and achieve the purpose of preventing clogging, prolonging life, and reducing damage to operation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~11

[0076] Embodiment 1~11 and comparative example 1~4

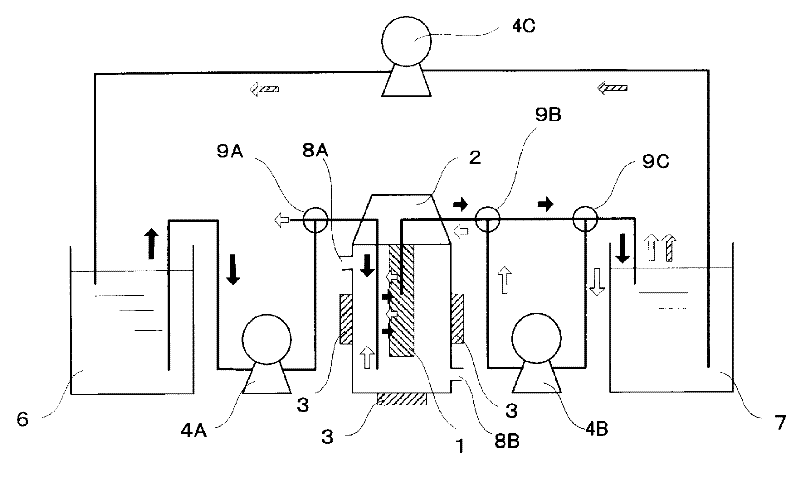

[0077] As the liquid to be filtered, a dispersion containing silica gel having an average particle diameter of 50 nm measured by the BET method at a concentration of 40% by weight was prepared. On the other hand, a tubular membrane filter (filter size: about 50 mm in total length; about 70 mm in outer diameter and 25 to 30 mm in inner diameter) contained in a resin cartridge with a total length of about 50 mm described in Table 1 was installed in the filtration device, and a diaphragm pump was used. Filtration is performed at an air supply pressure of 0.25Mpa. Continue to filter until the filter cannot be filtered due to clogging, and measure the volume (A) of the filtered dispersion.

[0078] Next, regenerate the used filter. Pass 5L of pure water into the filter that has finished filtering, then remove the filter, put the filter into the bath of the ultrasonic device and fill it with water, with an output power of 0.7W...

Embodiment 12

[0103] Using the same filtration device and filter as in Example 1, a filtration experiment was performed while irradiating 38 kHz ultrasonic waves. Compared with Example 1, the time until the filter clogged was extended to 1.5 times. In addition, the filter regeneration rate and filtration accuracy are the same as in the case of Example 1.

Embodiment 13 and 14

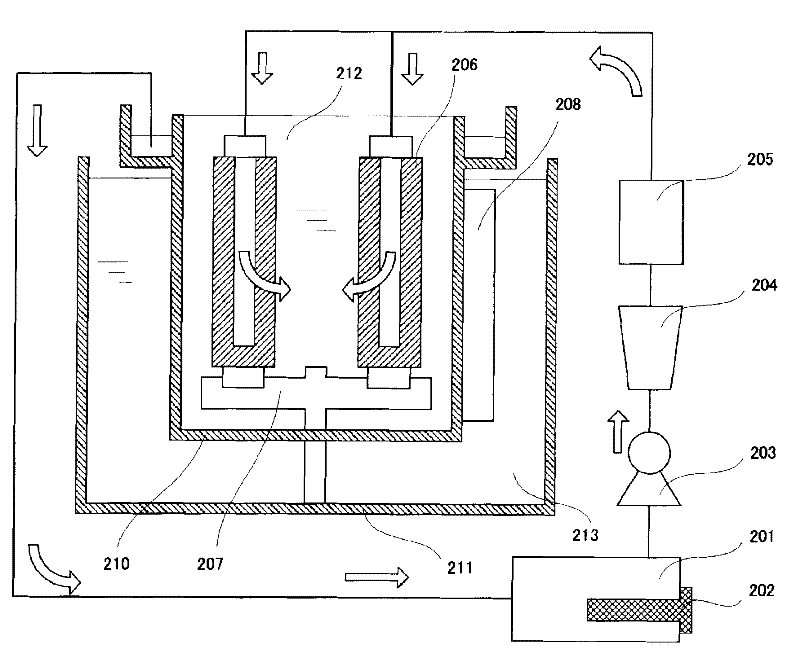

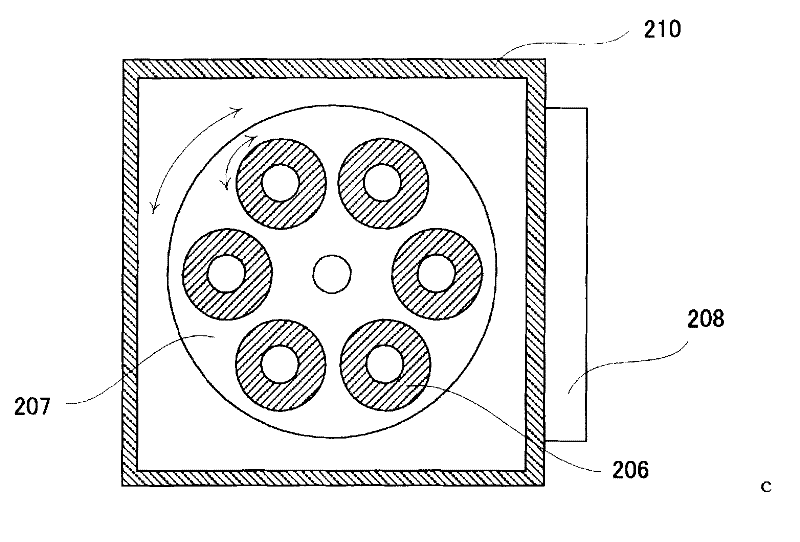

[0105] As a liquid to be filtered, a dispersion containing silica gel having an average particle diameter of 35 nm measured by the BET method (70 nm measured by the light scattering method) at a concentration of 20% by weight was prepared. On the other hand, a nylon membrane filter (filter size total length about 50 mm; outer diameter about 70 mm, inner diameter 25 to 30 mm) housed in a resin cartridge with a total length of about 50 mm and an opening of 0.2 μm was set in the filtration device, and a diaphragm was used. The pump is filtered with an air delivery pressure of 0.25Mpa. After filtering until it cannot be filtered due to clogging, pass such as figure 2 The shown filter regeneration device regenerates the filter. When the frequency of the irradiated ultrasonic waves was kept constant at 38 kHz (Example 13), the regeneration rate was 42%, but when the frequency was modulated at ±5% (Example 14), the regeneration rate was 55%, and further Improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com