Liquid test strip

A fluid detection and test piece technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of flow channel blockage, measurement error, test failure, etc., to avoid blocking flow channels, accurate quantitative analysis results, and avoid liquid residues Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Since the present invention discloses a test piece for fluid detection, the physical and chemical principles and solution coating technology used in it are already understood by those with ordinary knowledge in the relevant technical field, so the following description will not be fully described. At the same time, the drawings compared below are schematic representations related to the features of the present invention, and are not and need not be completely drawn according to the actual situation, so they will be described here first.

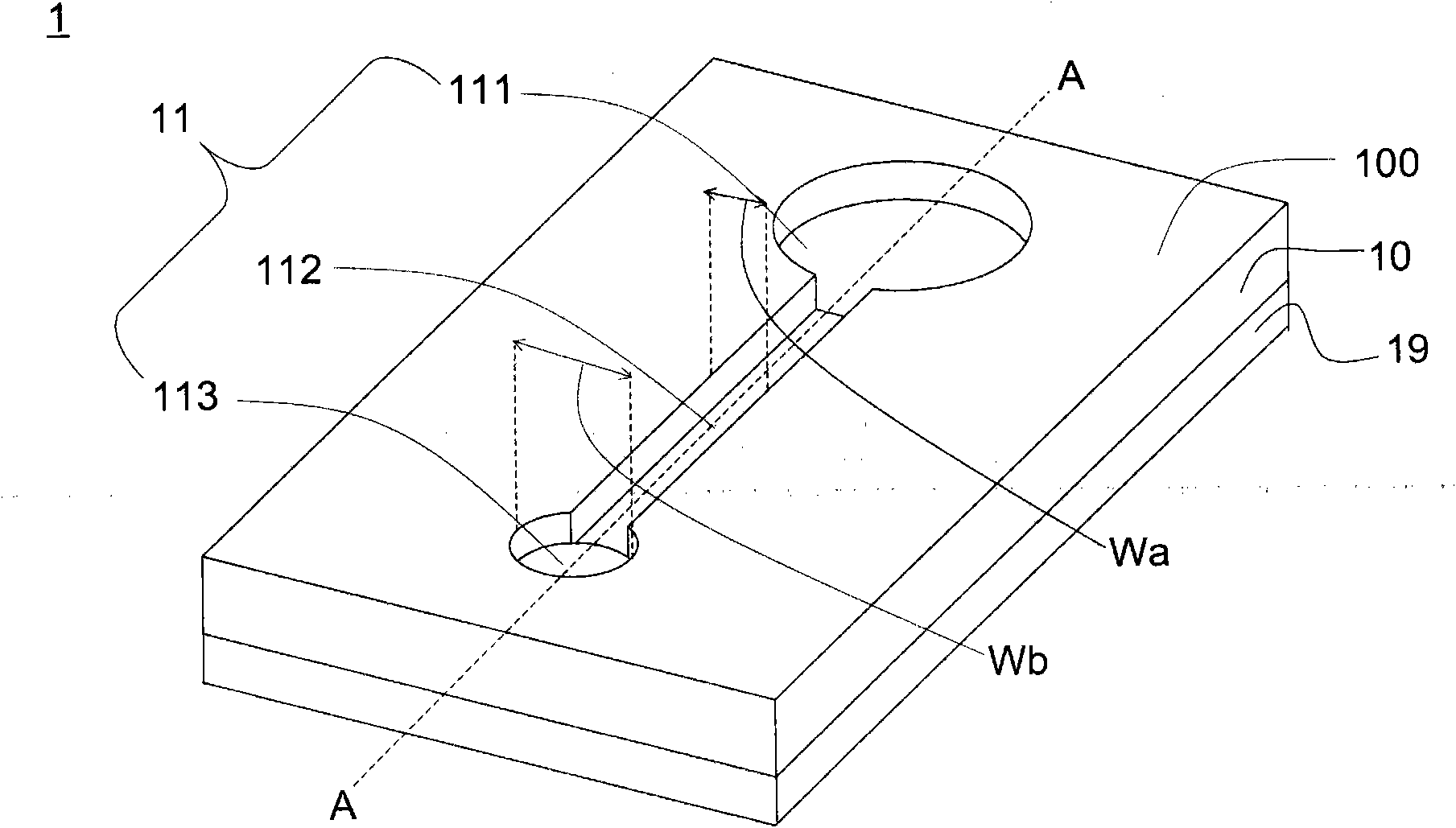

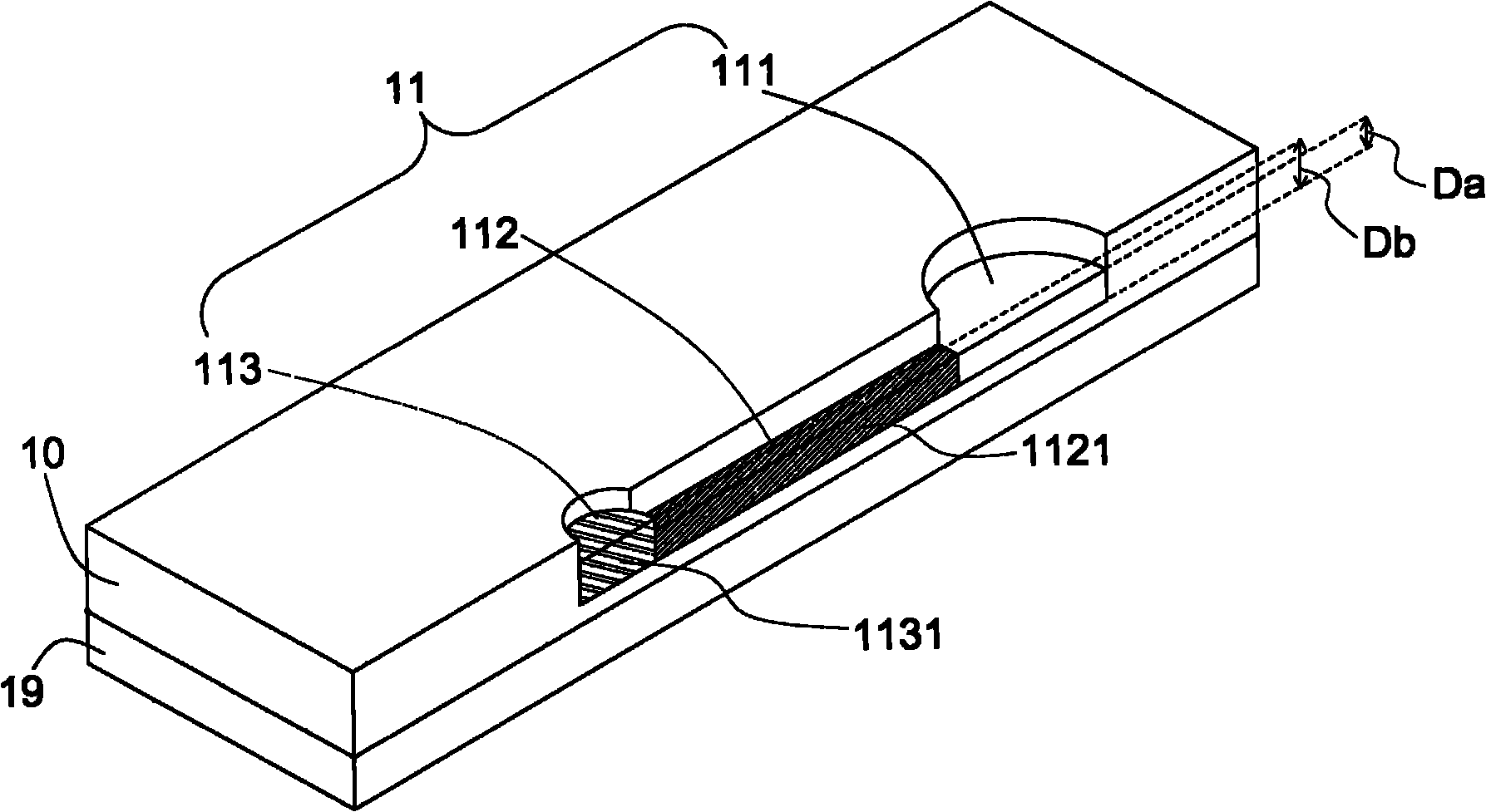

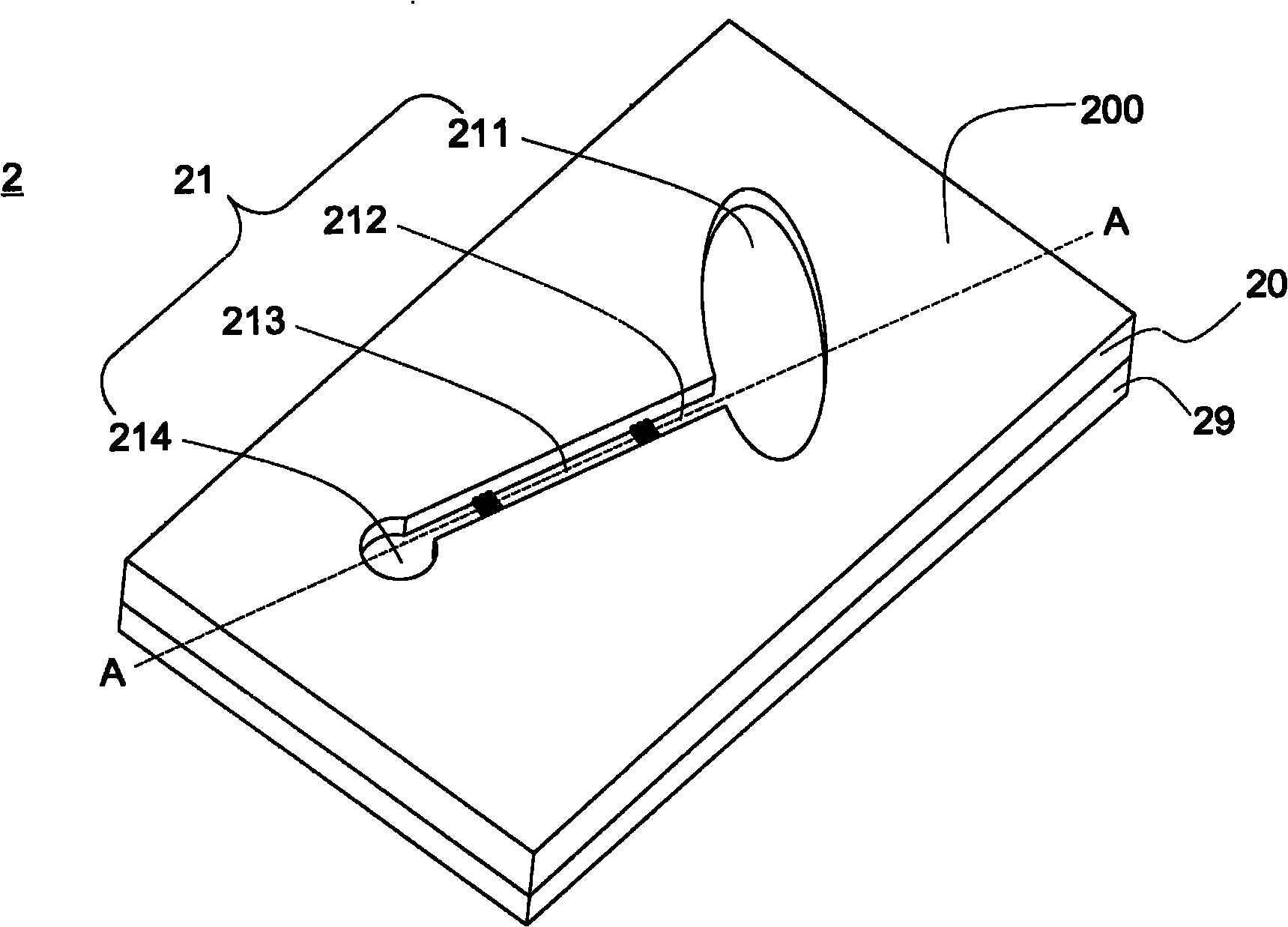

[0032] Such as Figure 1A Shown is a schematic diagram of the first embodiment of the present invention. The fluid detection test strip 1 includes a substrate 10 and a support 19 . The substrate 10 is recessed from the upper surface 100 to define a flow channel 11 , and the flow channel 11 includes a first fluid area 111 , a second fluid area 112 and a third fluid area 113 connected in sequence. The first fluid area 111 is used for th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com