Long-distance automatically feeding device

An automatic baiting, long-distance technology, applied in the field of fishery and aquaculture, can solve the problems of constraints, increase labor costs, and cannot automatically cast bait over long distances, and achieve the effect of a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

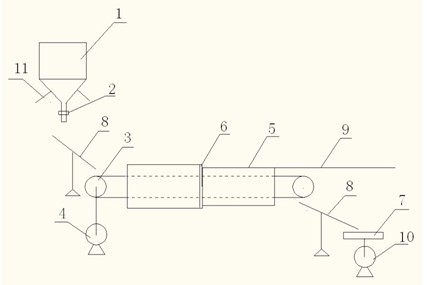

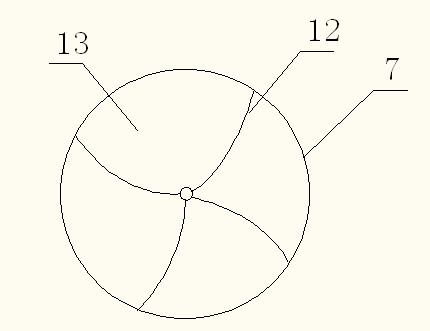

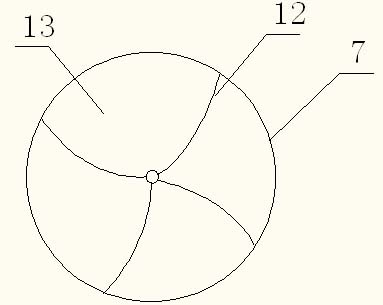

[0015] As shown in the figure, the figure includes: hopper 1, solenoid valve 2, feed conveyor belt 3, motor 4, casing 5, fastening device 6, feeder 7, feed guide plate 8, baffle plate 9, power device 10, Rainproof cap 11, feeding deflector 12, base plate 13.

[0016] As shown in the figure, the hopper outlet at the lower part of the hopper 1 transmits the feed to the feed conveyor belt 3 through the feed guide plate 8, and adjusts the discharge through the solenoid valve 2. The lower part of the hopper is provided with a rainproof cap 11. The feed conveyor belt 3 is installed in the sleeve pipe 5 and is driven by the motor 4 to run. The casing is a multi-layer telescopic casing, and the casings are connected by a fastening device 6. Such a design can take into account the adjustment of the feeding distance, and is also convenient for maintenance. The casing is provided with a baffle 9 at the outlet of the feed conveyor belt 3 . The lower part of the feed conveyor belt is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com