Special automatic welding rotation equipment of concrete mixer chassis

A technology for concrete mixer trucks and special equipment, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of welding seams that cannot be welded and welded, and achieve compact structure, simple operation, and improved The effect of welding quality and welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

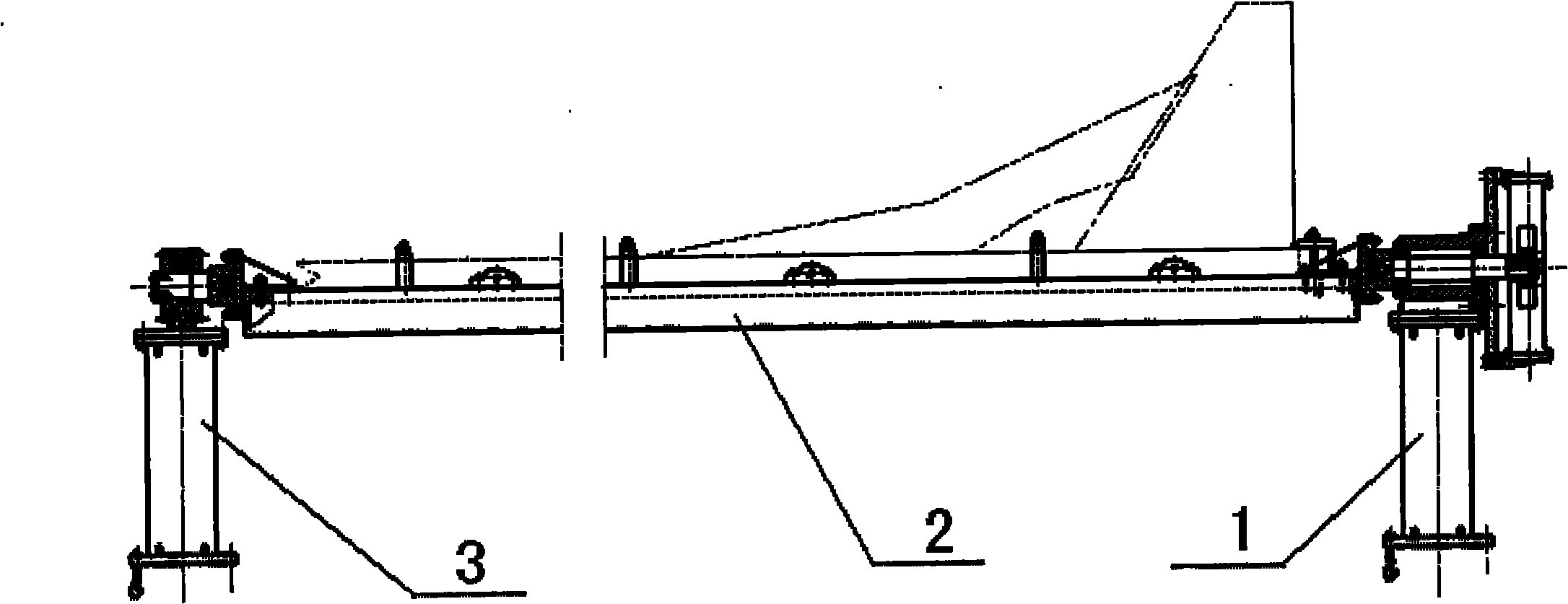

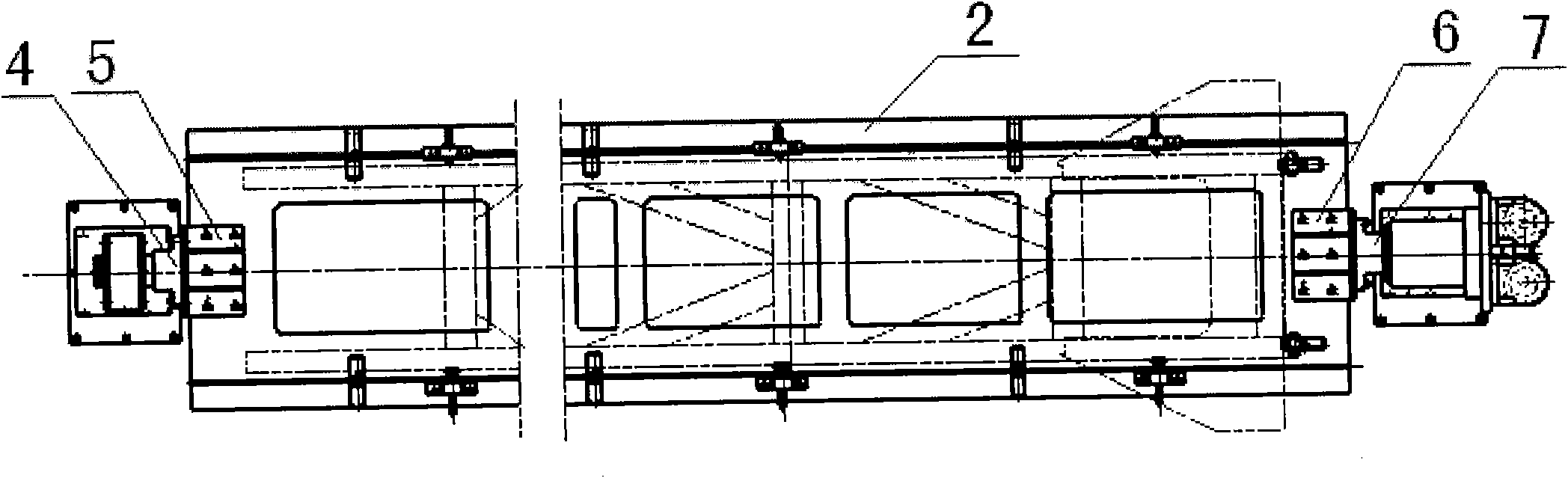

[0019] refer to Figure 1-Figure 6 , the special equipment for automatic welding and rotation of the underframe of a concrete mixer truck in this embodiment includes a workbench 2 and an active device 1 provided at both ends of the workbench to provide power and a driven device 3 that plays a supporting role. The active device 1 and The worktables 2 are connected and fixed by the connection seat 6, and the driven device 3 and the workbench 2 are connected and fixed by the connection seat 5.

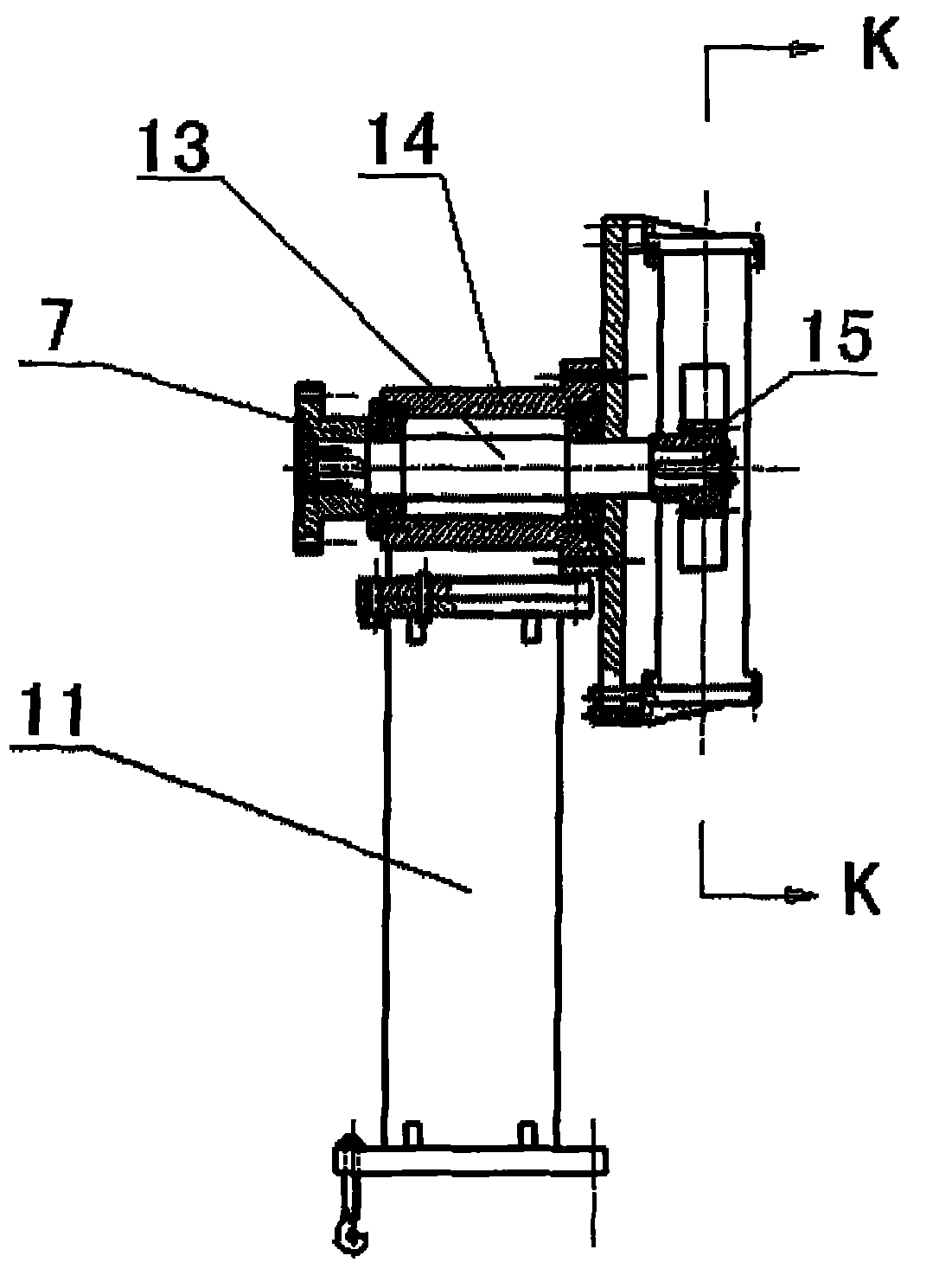

[0020] The active device 1 includes a base 11, a shaft seat 14 fixed on the base, a flange 7, a transmission shaft 13, a power unit, the transmission shaft 13 is arranged in the shaft seat 14, and one end of the transmission shaft 13 is connected to the flange 7 , the other end is connected to the power unit, and the flange 7 is fixedly connected to the workbench 2 through the connecting seat 6 . Described power unit comprises gear 15 and a pair of hydraulic cylinder 18 and 19, and gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com