Method and device for recycling multi-thread cutting machine mortar

A multi-wire cutting machine and mortar technology, applied in the direction of fine working devices, working accessories, stone processing equipment, etc., can solve the problems of reducing work efficiency, generating debris and chips, and increasing processing costs, so as to improve processing accuracy and processing Efficiency, reducing the possibility of clogged pipes, and extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

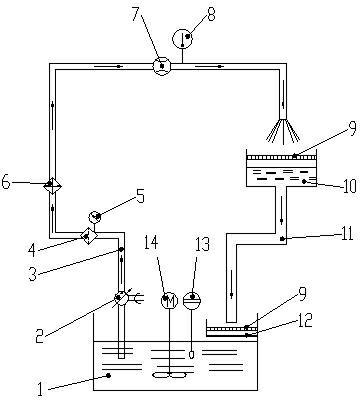

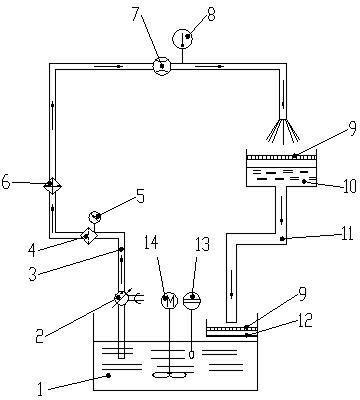

[0011] Depend on figure 1 It can be seen that a method for recycling mortar of a multi-wire cutting machine includes collecting the mortar after cutting and coarsely separating and filtering it; then, after performing a fine separation and filtering, it is sent into a mortar bucket with a stirring device; After the pump filters the mortar in the mortar tank through a bag filter and cools it with a heat exchanger, the mass flow meter supplies the mortar according to the flow demand of each sand supply pipeline, and then participates in cutting to achieve the purpose of recycling the mortar.

[0012] A multi-wire cutting machine mortar recycling device adopting the above method, it includes a liquid receiving tank 10 for collecting the cut mortar, a mortar bucket 1, a coarse filter screen 9 is arranged on the liquid receiving tank 10, and the liquid recei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com