Multifunctional hydraulic pile hammer

A multi-functional pile driver technology, applied in the direction of mechanical equipment, reciprocating drilling rigs, rotary drilling rigs, etc., can solve the problems of loose soil and rock structure around the pile body, slow pile driving speed, and poor stability of the pile body, so as to save time and Cost, low cost, smooth operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

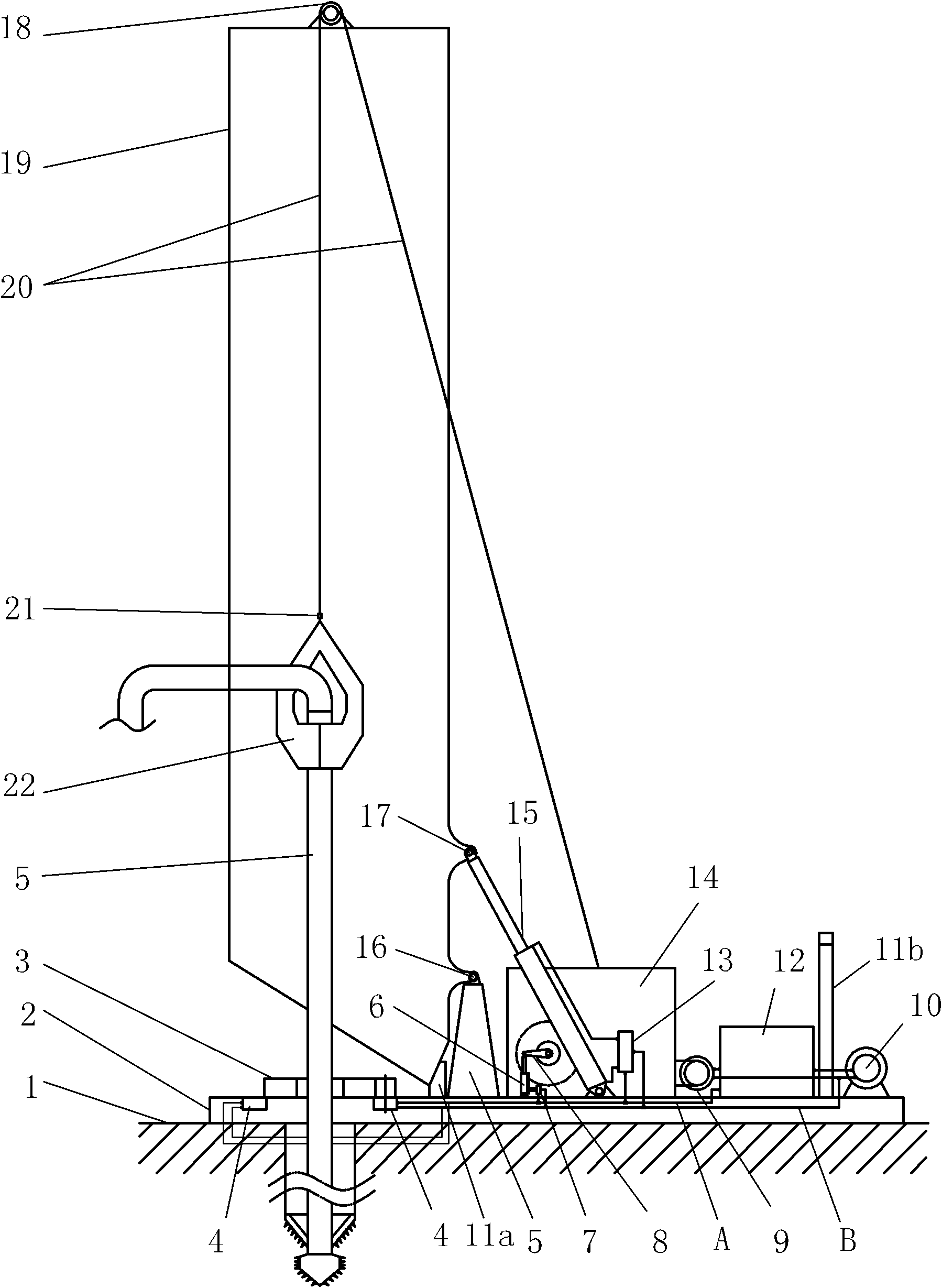

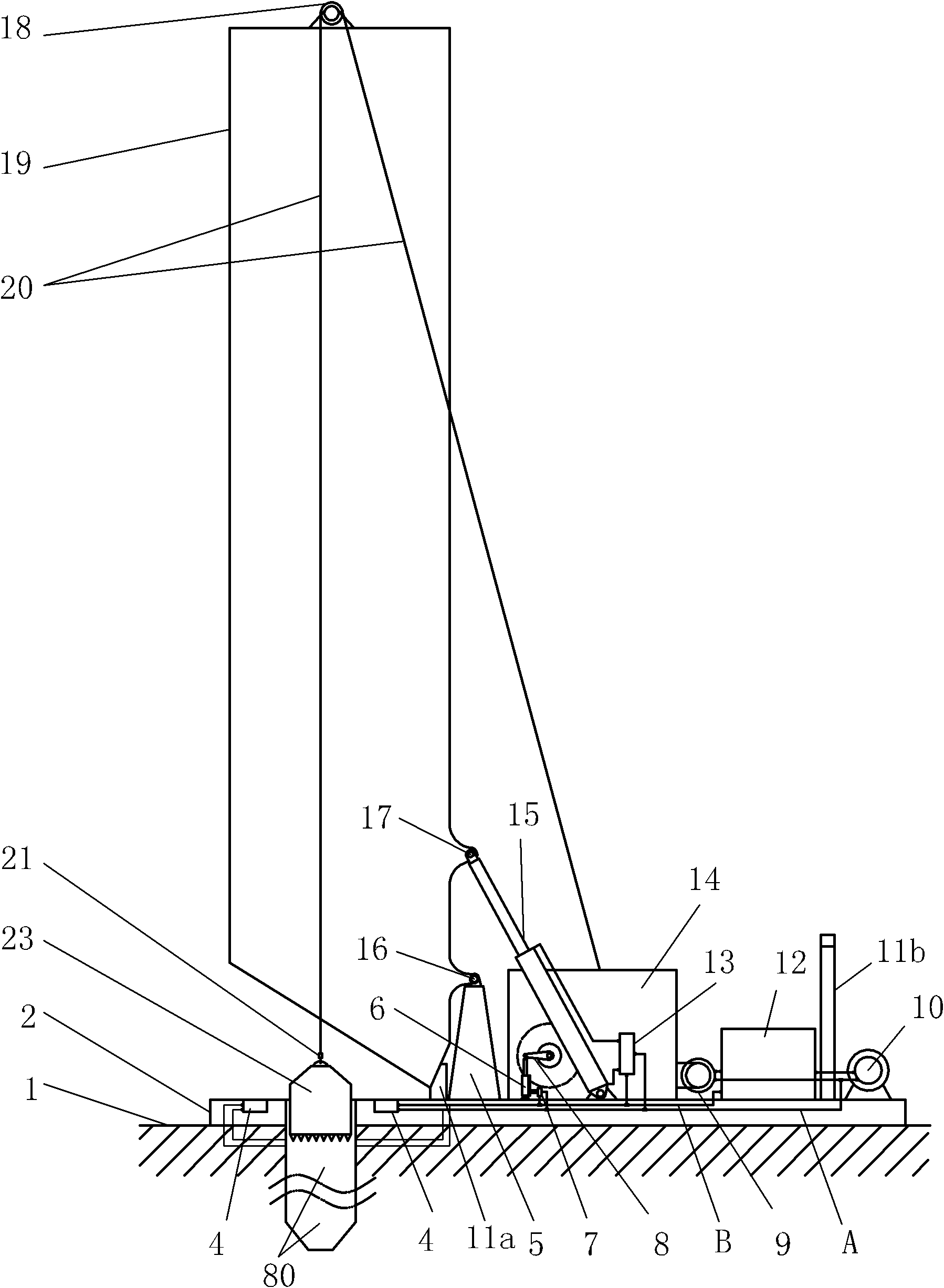

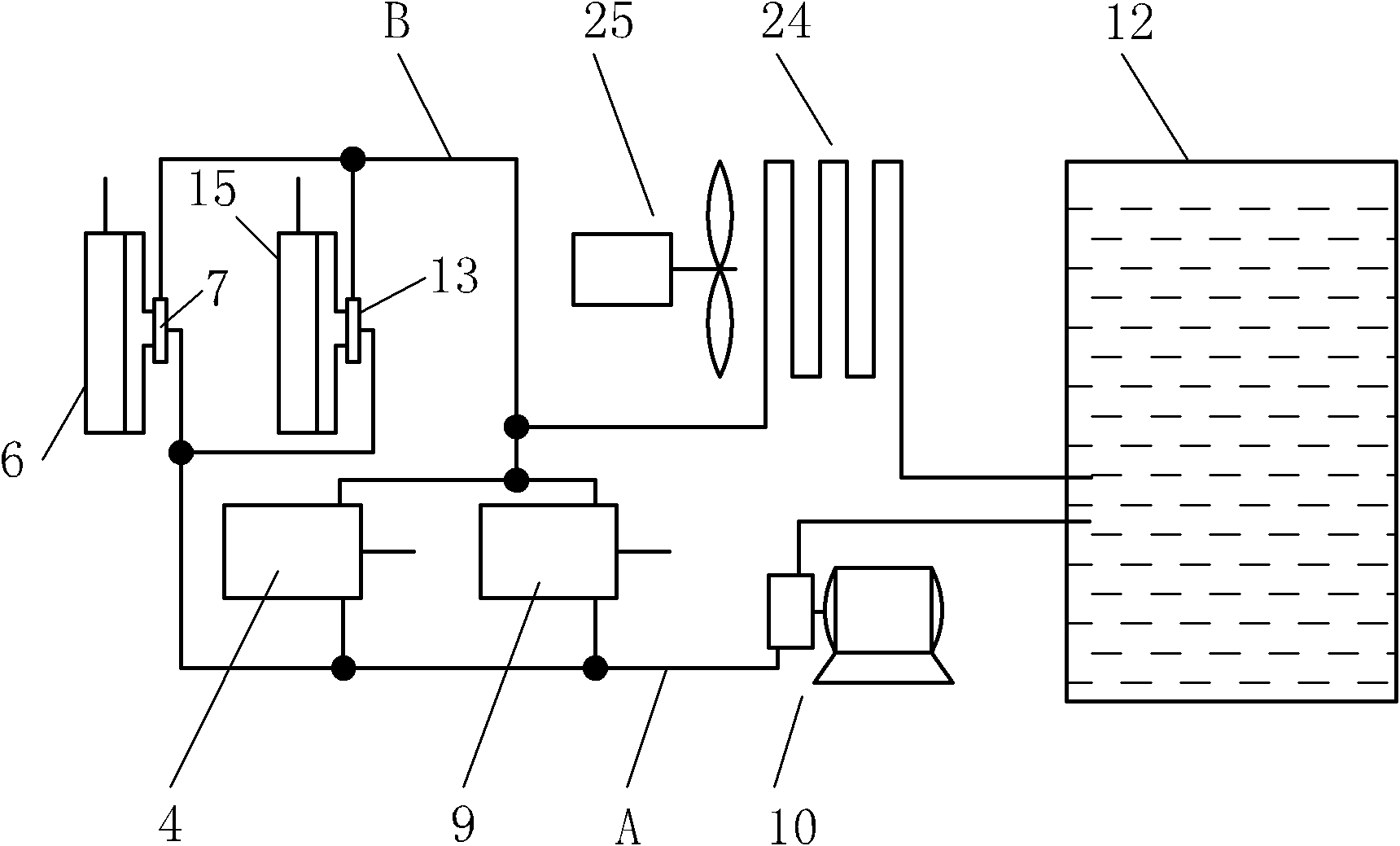

[0019] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see Figure 1-4 :

[0020] The multifunctional hydraulic pile driver includes a base 2, a hoist 14 and a gantry 19. A drill pipe clamp 3 is arranged at one end of the base 2, and the drill pipe clamp 3 is driven to rotate by the first hydraulic motor 4 of the hydraulic system. The hoist 14 The second hydraulic motor 9 of the hydraulic system drives it to rotate, and one end of the gantry 19 is hinged on the base stand 5 next to the drill pipe fixture through the rotating shaft 16, and is driven by the first hydraulic cylinder 15 to stand up or fall down. , the base 2 is provided with a stop block 11a for erecting the gantry 19 and a support 11b for falling down, the top of the gantry 19 is provided with a pulley 18, and the extension end 21 of the steel cable 20 driven by the hoist 14 passes through the pulley 18 and the drill. The rod suspension fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com