Exhaust gas treatment device

A waste gas treatment device and exhaust system technology, which is applied in the direction of exhaust devices, mufflers, gas passages, etc., and can solve problems such as high loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

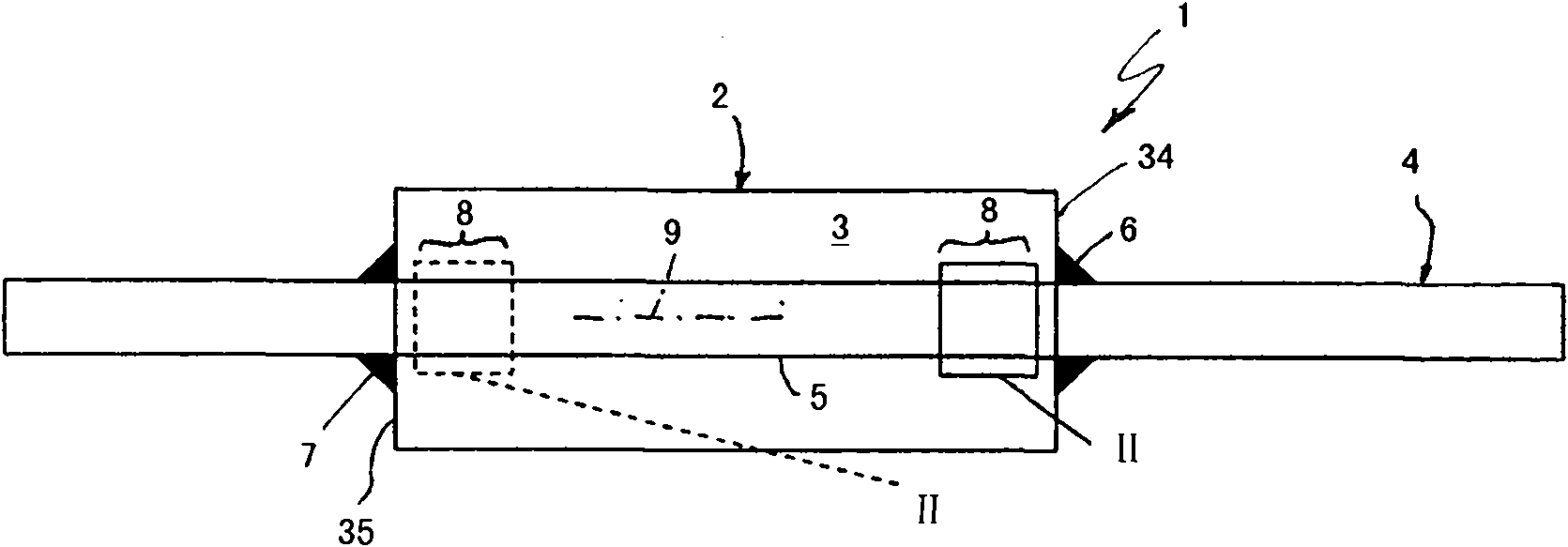

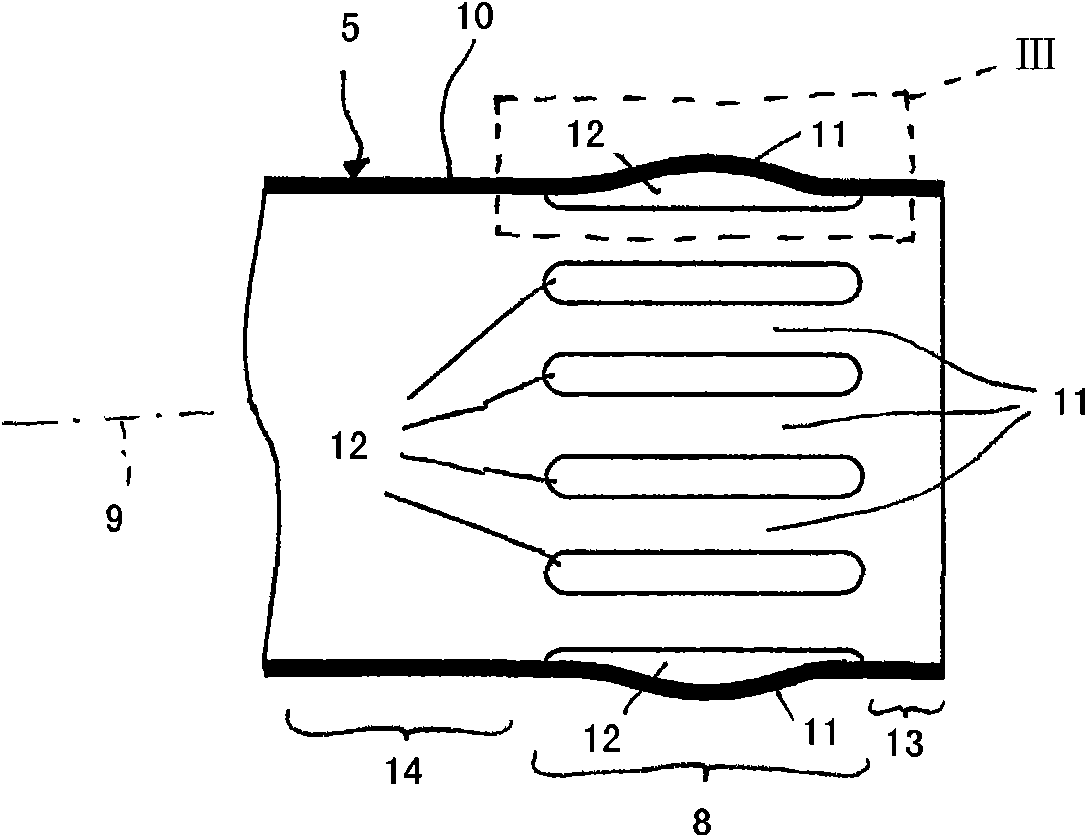

[0028] according to figure 1 , the exhaust gas treatment device 1 comprises a housing 2 which encloses at least one interior space 3 . The exhaust gas treatment device 1 is used for an exhaust system 4 of an internal combustion engine (only partially visible here), which can preferably be accommodated in a road vehicle. The exhaust gas treatment device 1 can be a catalytic converter, for example an oxidation catalytic converter or a NOx storage catalytic converter or an SCR catalytic converter. The exhaust gas treatment device 1 can also be a particle filter, more preferably a soot filter. Furthermore, the exhaust gas treatment device 1 may be a silencer. It also concerns any combination of basic catalytic converters, particulate filters and / or mufflers. Particularly, figure 1 and 4 Only a part of the exhaust gas treatment device 1 is shown in each case.

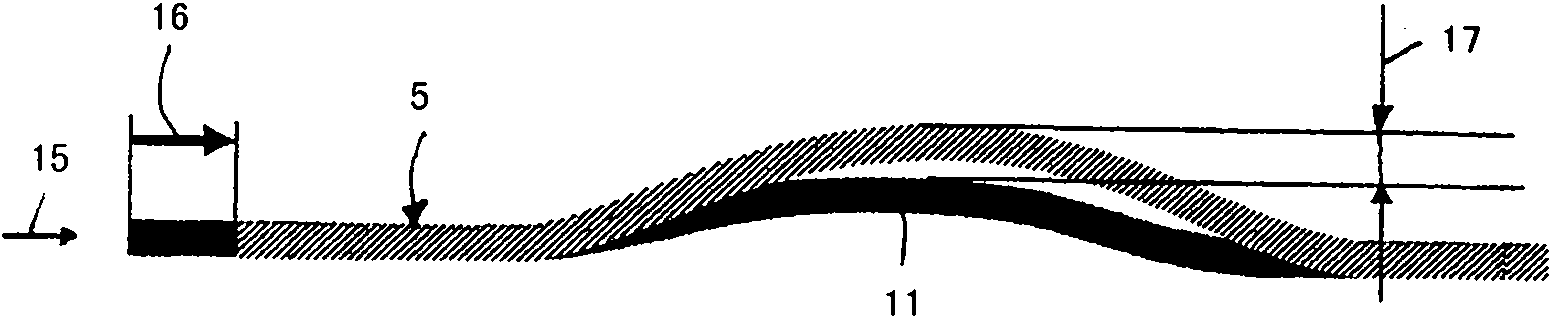

[0029] figure 1 The exhaust gas treatment device 1 in the exemplary embodiment shown comprises at least one through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com