Vacuum energy all-weather S-shaped airfoil rotational flow power generating system

A power generation system, all-weather technology, applied in wind power generation, renewable energy power generation, machines/engines, etc., can solve problems such as difficult installation and application, difficult installation and use, ecological impact, etc., to improve efficiency, low cost, and easy processing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

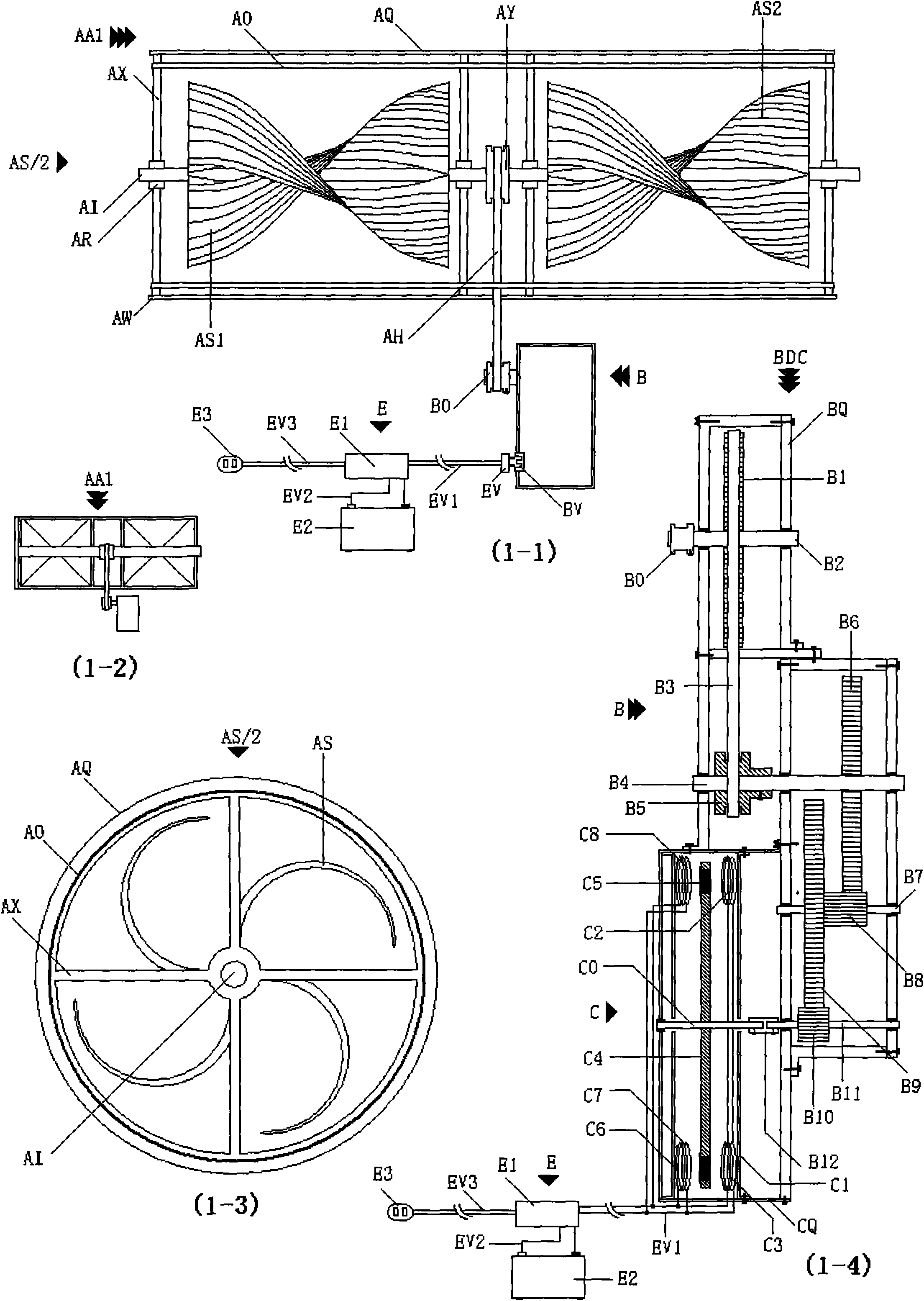

[0084] exist figure 1 , 2 Middle: S-type impeller airflow generator (AA1), referred to as: S-type generator (AA1); S-type impeller device (AS / 2), referred to as: S-type impeller (AS / 2); magnetic rotary power storage device (BCE ), referred to as: magnetic generator / storage device (BCE); fixed bracket (AX), frame (AQ), poly flow cover (A0), connecting ring (AW), S-shaped impeller (AS), S-shaped impeller (AS1) , S-shaped impeller (AS2), 1st stage transmission shaft (AI), bearing (AR), 1st stage transmission wheel (AY), 1st stage transmission belt (AH), speed increaser (B), magnetic generator / storage device (BCE ), 3rd stage transmission wheel (B1), 2nd stage transmission shaft (B2), 2nd stage transmission wheel (B0), 2nd stage transmission belt (B3), 3rd stage transmission shaft (B4), 4th stage transmission wheel (B5), 5 Stage transmission gear (B6), 4 stage transmission shaft (B7), 6 stage transmission gear (B8), 7 stage transmission gear (B9), 8 stage transmission gear (B10)...

Embodiment 2

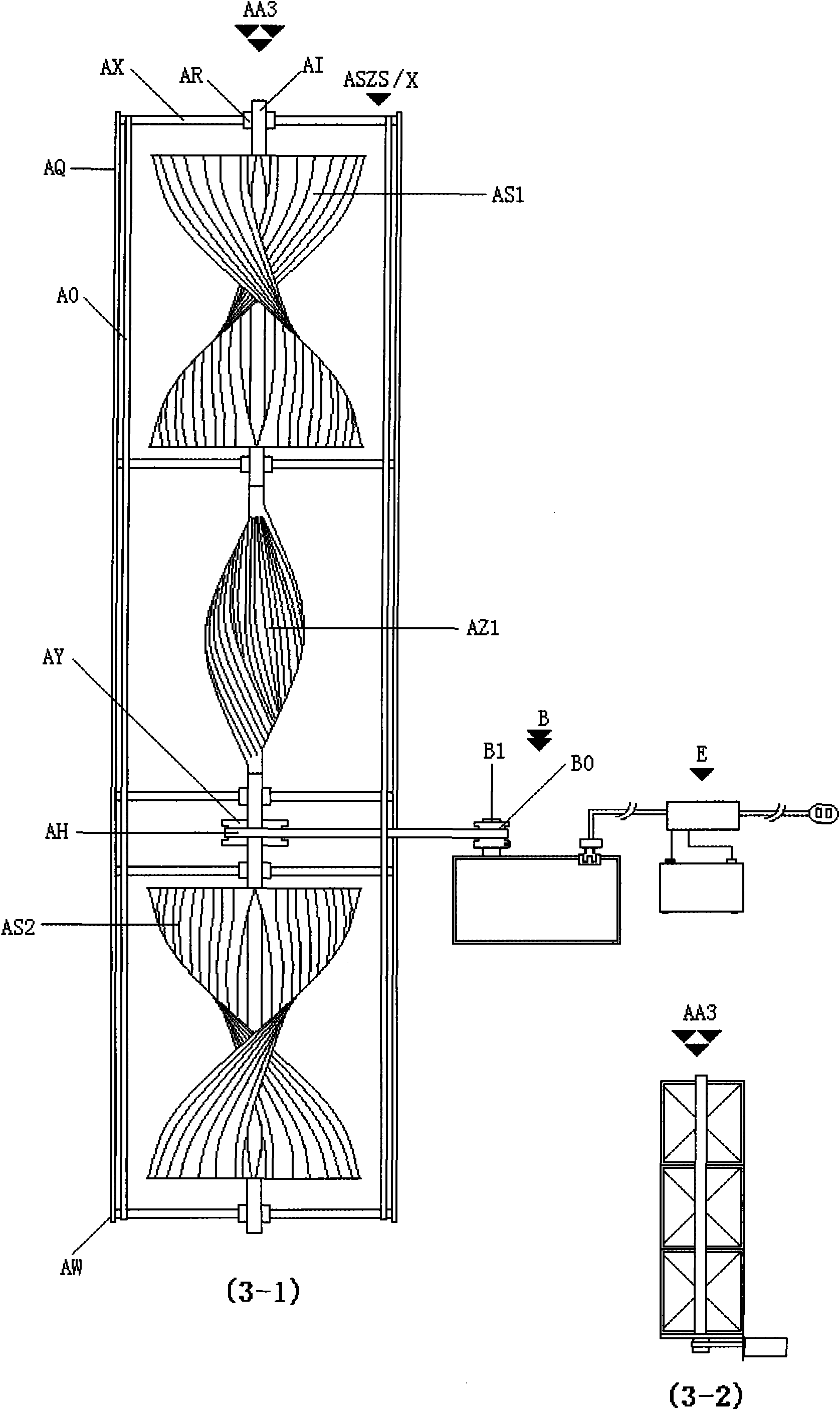

[0087] exist image 3 , 4 Middle: SZS generator (AA3), SSS generator (AA4), SZS impeller airflow device (ASZS / X), (AZ1) S-shaped impeller, S-shaped impeller (AS1), S-shaped impeller (AS2), S-shaped impeller (AZ1), connecting ring (AW).

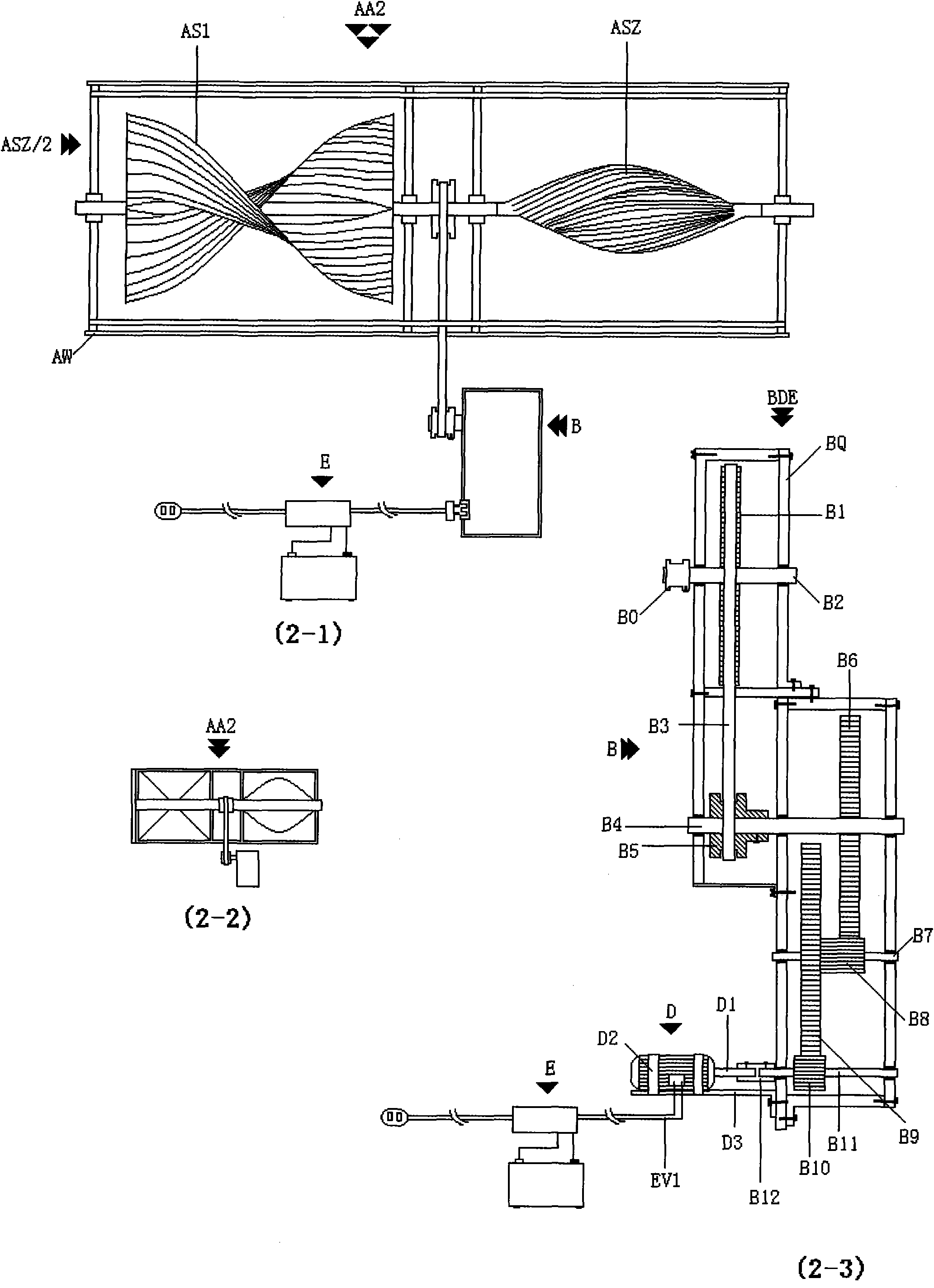

[0088] In the figure: the overall structure is the same as figure 1 and 2 As shown in , the difference is; the SZS generator (AA3) is spirally connected to the S-shaped impeller (AS1) and the S-shaped impeller (AS2) at both ends of the first-stage transmission shaft (AI); the middle connection The Z-shaped impeller (ASZ) is 90 degrees with the S-shaped impeller (AS1) and the S-shaped impeller (AS2);

[0089] The SSS generator (AA4) is spirally connected with the S-shaped impeller (AS1) and the S-shaped impeller (AS2) at the two ends and the middle of the first-stage transmission shaft (AI).

Embodiment 3

[0091] exist Figure 5 Middle: wing S impeller type airflow generator (AA5), abbreviation: wing S impeller generator (AA5); wing blade (QQ), air intake channel (AG), connecting pipe seat (AK), air exhaust Outlet (AU), Upward Swirl (N6), Swirl (N6-1), Swirl S Blade Rotation (N6-2), Swirl S Blade Rotation (N6-3), Exhaust Airflow (N6-4).

[0092] In the figure: the S-type generator (AA5) includes a fixed support (AX) connected in a circular outer frame (AQ), and a heat-preserving air-gathering cover (A0) is connected outside the fixed support (AX); The center of the fixed bracket (AX) is connected to the bearing (AR), and the first-stage transmission shaft (AI) is connected to the bearing (AR), and the two ends of the first-stage transmission shaft (AI) are spirally connected to the S-shaped impeller (AS1 ) and S-shaped impeller (AS2); at the same time, the wing frame (QX) is connected in the bearing (AR), and the wing blade (QQ) with adjustable angle is connected to the outer r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com