Diaphragm pump for fluid

A technology for diaphragm pumps and fluids, which is applied to parts, pumps, and pump components of pumping devices for elastic fluids, and can solve the problems of high probability of loss or damage, easy failure reliability, and difficulty in miniaturization of diaphragm pumps, etc. problems, to achieve easy and rapid manufacturing, reduce manufacturing workload, and reduce the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Hereinafter, the present invention will be described in detail based on the illustrated embodiments.

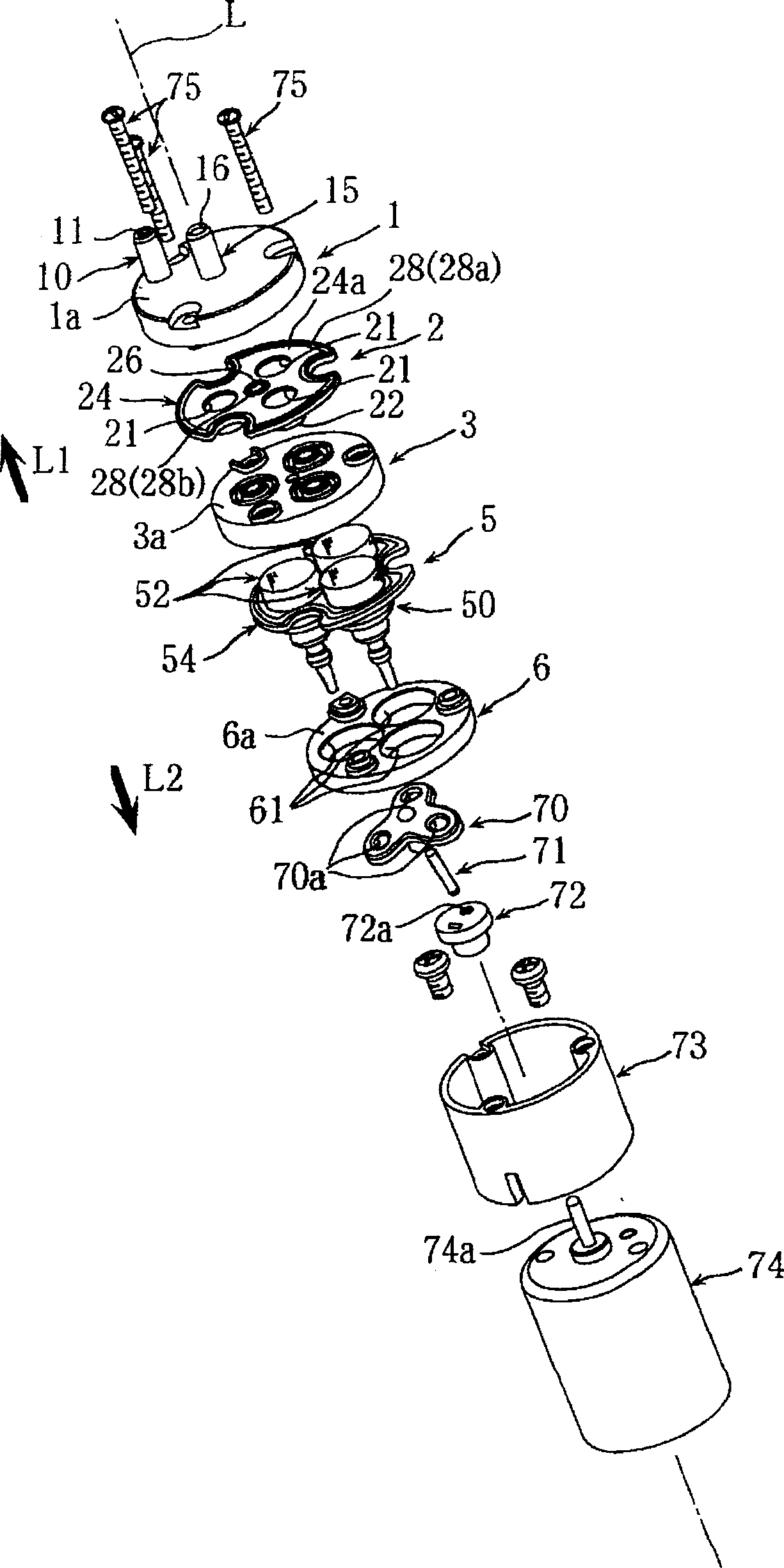

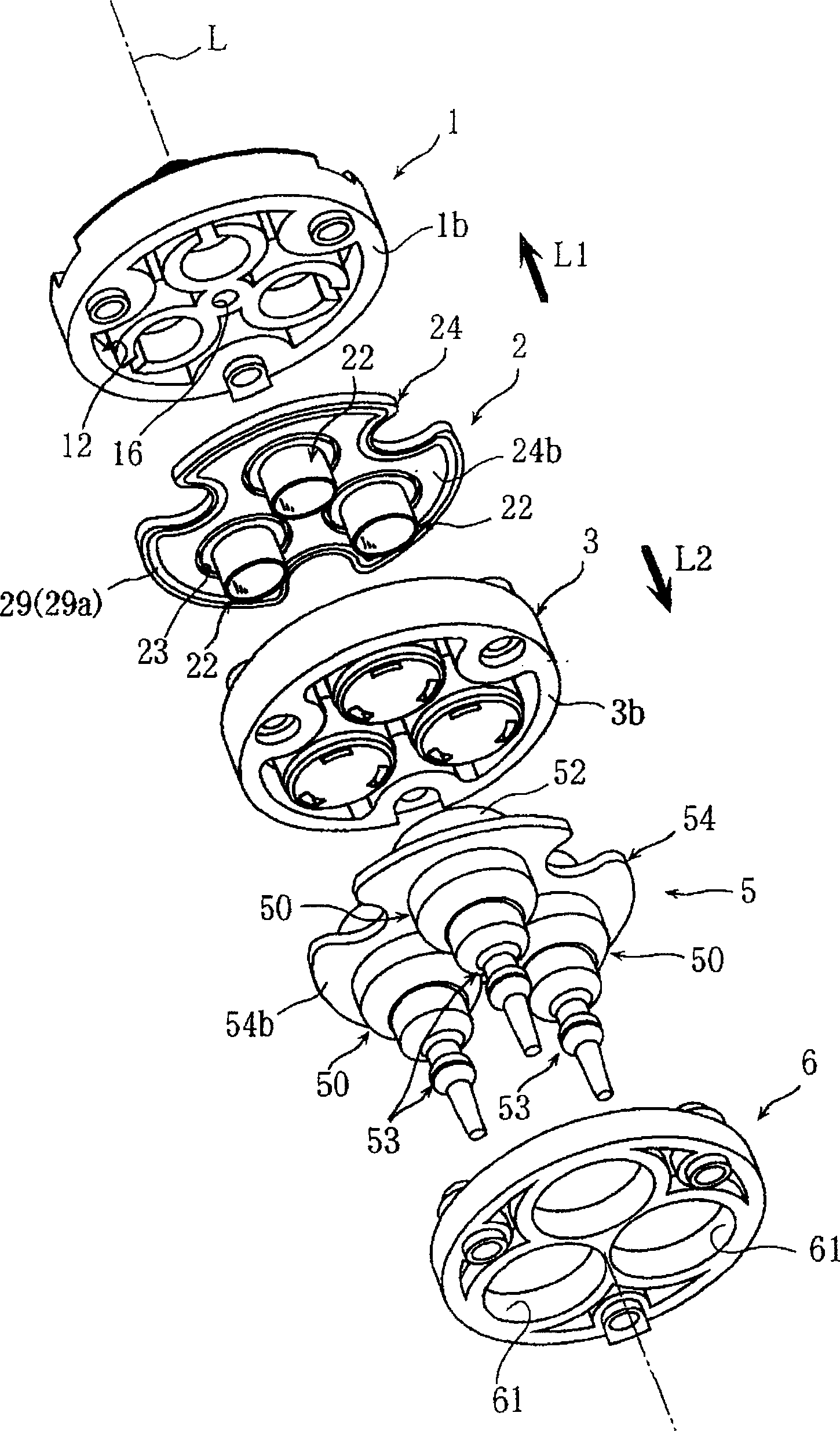

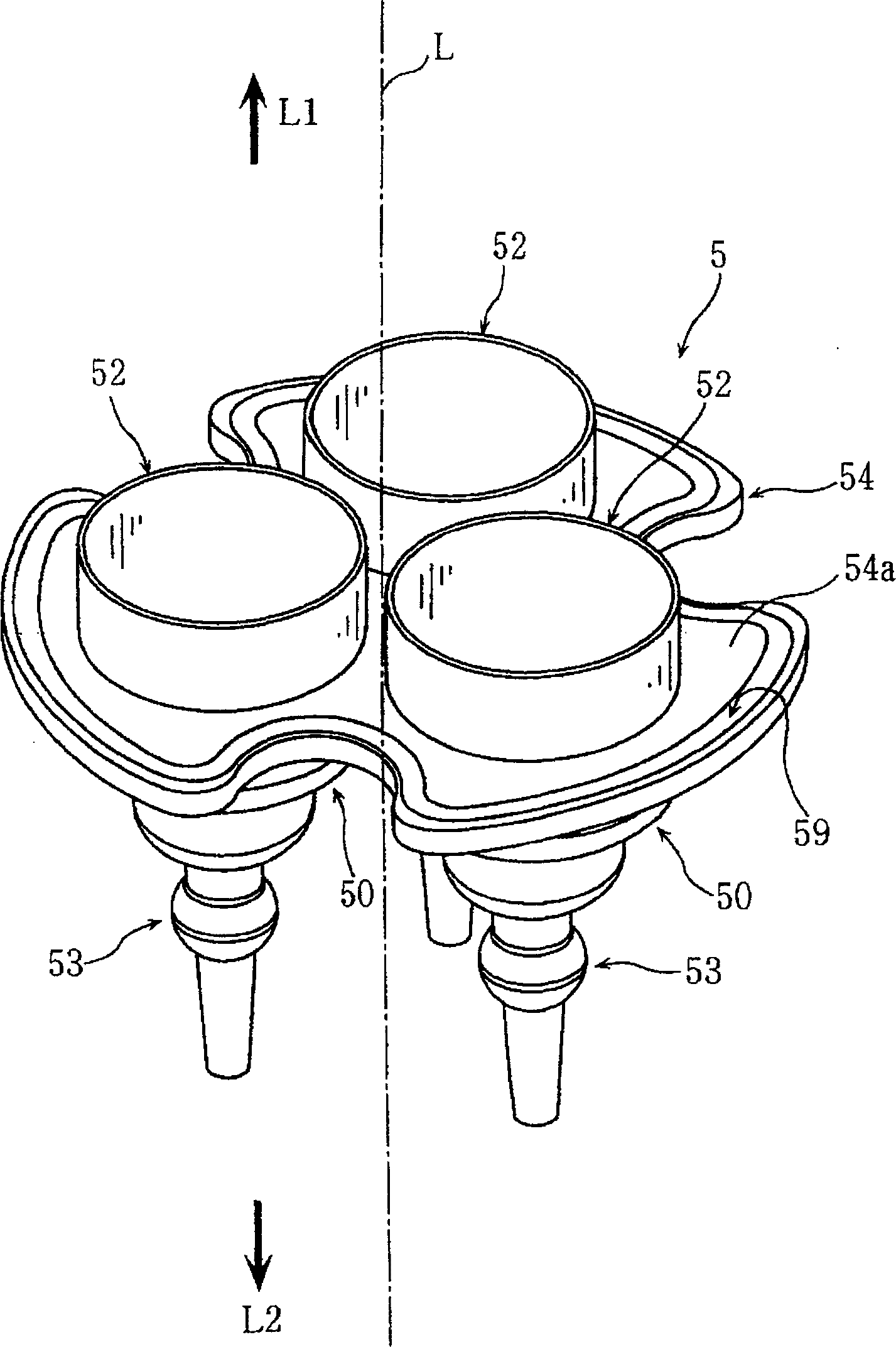

[0038] exist figure 1 and figure 2 Among them, the fluid diaphragm pump of the present invention has: a cover 1 having a small cylindrical suction port 10 and a discharge port 15 protruding in one direction L1 of the axis; The suction valve membrane assembly 2 of the short cylindrical suction valve membrane 22; the diaphragm assembly 5 with three bowl-shaped diaphragms 50 opening to the axial direction L1; installed between the suction valve membrane assembly 2 and the diaphragm assembly 5 The middle cover body 3; the holding member (support member) 6 that contacts and supports the diaphragm assembly 5 from the other axis direction L2 side.

[0039] In addition, in the present invention, the central axis of the entire diaphragm pump for fluid is referred to as the axis L. In addition, the arrow L1 direction side along the axis L is referred to as an axis-one direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com