Ultrahigh heat density cooling system

A cooling system, ultra-high heat technology, used in cooling/ventilation/heating renovation, instruments, electrical digital data processing, etc., can solve the problems of cooling system interference, vibration and noise, and achieve the effect of reducing noise and improving cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

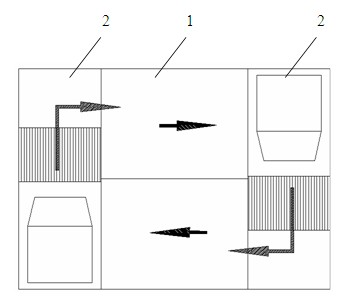

Embodiment 1

[0031] This cooling solution is specially designed for high-performance computers or large-scale data centers with ultra-high heat density cooling solutions. The ultra-high heat density cooling system in this embodiment is a multi-rack and multi-air conditioner series fully enclosed air cooling circulation system (hereinafter referred to as: cooling circulation system). The cooling circulation system includes air conditioning equipment, and the air conditioning equipment includes Two-layer cooling cycle, refrigeration host and cooling terminal. The first layer of cooling cycle includes pumps, air-fluid heat exchangers, and fluid-fluid heat exchangers. The cooling cycle uses volatile working fluids to transfer heat; the second layer of cooling cycles uses A cold water system that transfers heat from a fluid-fluid heat exchanger to the environment, or a vapor compression system that transfers heat from a fluid-fluid heat exchanger to the environment. The cooling host and the cool...

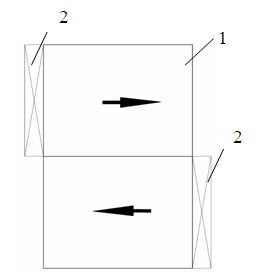

Embodiment 2

[0044] like figure 2 , 4 As shown, the difference between this embodiment and the foregoing embodiment 1 is that when the rack server 1 has sufficient air volume, the cooling terminal 2 can cancel the fan and only retain the heat exchanger. Cooling terminal 2 is arranged as Image 6 As shown (but without fan 57), after the cryogenic liquid enters the cooling terminal 2 through the pipeline, it first passes through the flow regulating valve 58 (the flow regulating valve 58 is used to control the flow of the cryogenic liquid), and the cryogenic liquid comes out of the flow regulating valve 58 and then Enter the air-fluid heat exchanger 56, in the air-fluid heat exchanger 56 due to absorbing the heat of the air side of the air-fluid heat exchanger 56, a phase change process occurs from liquid to gas, in the air-fluid heat exchanger 56 The outlet low-temperature fluid has been transformed into high-temperature gas, and flows out of the cooling terminal 2 through the pipeline sy...

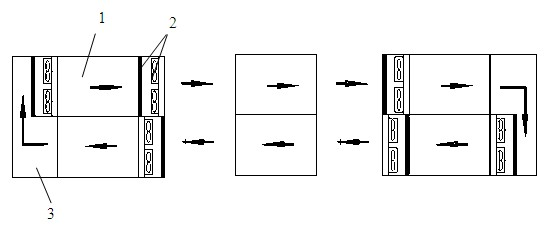

Embodiment 3

[0048] As a more preferred embodiment, the cooling terminal in this embodiment adopts a microchannel heat exchanger, and the thickness of the microchannel heat exchanger can be more than 70% smaller than common radiators such as copper tube fin heat exchangers, etc. The air resistance of the micro-channel heat exchanger is also much smaller, so the thickness of the cooling terminal in this embodiment can be made very small, thereby further saving valuable space in the machine room.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com