Digital closed circuit TV (television) cable for marine engineering and manufacturing method thereof

A marine engineering and closed-circuit television technology, which is applied in the direction of cable/conductor manufacturing, power cables, insulated cables, etc., can solve the problems of low strength of twisted wires, poor shielding effect, and easy to be messy, so as to avoid signal interference and carry Convenience, the effect of reducing signal noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

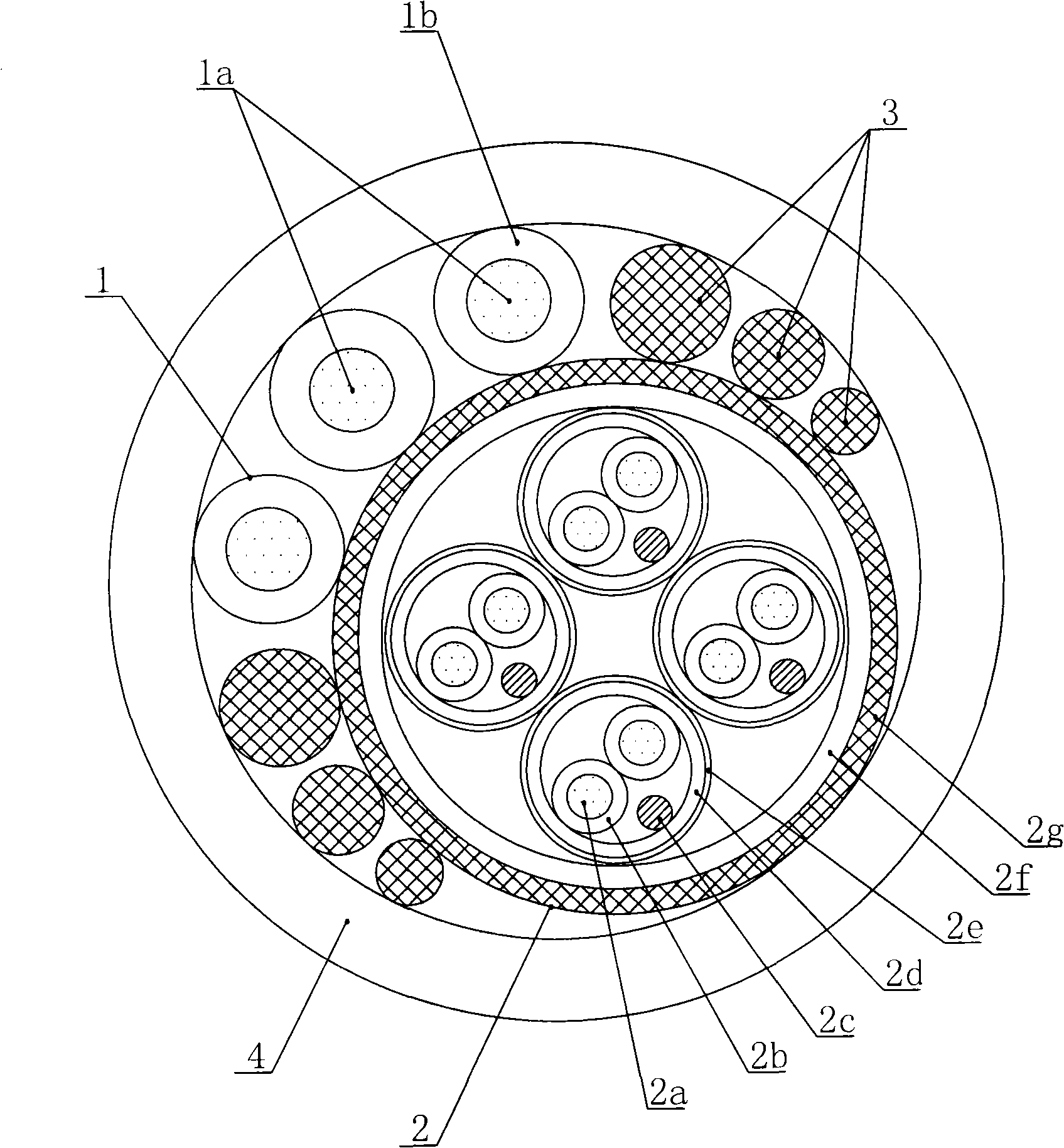

[0017] (1) Twisting forty-nine tinned copper wires with a diameter of 0.25mm into a power cable conductor 1a, the stranded pitch ratio is 9 times; The power cable 1 is formed by extruding the insulating layer 1b of the power cable with halogen material, and the extruded thickness is 0.6mm;

[0018] (2) Twisting seven tinned copper wires with a diameter of 0.2mm into a twisted pair conductor 2a, the twisted pitch ratio is 8 times; the outer circumference of the twisted pair conductor 2a adopts a low-density flame-retardant non-woven fabric with high insulation resistance The insulating layer 2b of the twisted wire extruded with halogen material, the extruded thickness is 0.3mm, and the outer diameter of the insulation is 1.1mm; two insulated core wires are twisted into a twisted pair, and the twisted pitch ratio is 9 times;

[0019] Twisting seven tinned copper wires with a diameter of 0.2 mm into a drain wire 2c, the twisted pitch ratio is 8 times;

[0020] Wrap aluminum foil...

Embodiment 2

[0025] (1) Twisting forty-nine tinned copper wires with a diameter of 0.28mm into a power cable conductor 1a, the stranded pitch ratio is 12 times; The power cable insulation layer 1b is extruded with halogen material to form the power cable 1, and the extruded thickness is 0.8mm;

[0026] (2) Twisting seven tinned copper wires with a diameter of 0.24mm into a twisted pair conductor 2a, the twisted pitch ratio is 12 times; the outer circumference of the twisted pair conductor 2a is made of a low-density flame-retardant non-woven fabric with high insulation resistance. The insulating layer 2b of the twisted wire extruded with halogen material, the extruded thickness is 0.35mm, and the outer diameter of the insulation is 1.3mm; two insulated core wires are twisted into a twisted pair, and the twisted pitch ratio is 12 times;

[0027] Twisting seven tinned copper wires with a diameter of 0.24 mm into a drain wire 2c, the twisted pitch ratio is 12 times;

[0028] Wrap aluminum fo...

Embodiment 3

[0033] (1) Twisting forty-nine tinned wires with a diameter of 0.26mm into a power cable conductor 1a, the stranded pitch ratio is 10 times; The power cable insulation layer 1b is extruded with halogen material to form the power cable 1, and the extruded thickness is 0.7mm;

[0034] (2) Twisting seven tinned copper wires with a diameter of 0.22mm into a twisted pair conductor 2a, the twisted pitch ratio is 10 times; a low-density flame-retardant non-flammable wire with high insulation resistance is used on the outer circumference of the twisted pair conductor 2a The insulating layer 2b of the twisted wire extruded with halogen material, the extruded thickness is 0.32mm, and the outer diameter of the insulation is 1.2mm; two insulated core wires are twisted into a twisted pair, and the twisted pitch ratio is 11 times;

[0035] Twisting seven tinned copper wires with a diameter of 0.22 mm into a drain wire 2c, the twisted pitch ratio is 10 times;

[0036] Wrap aluminum foil pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com