Transistor epitaxially growing source/drain region and manufacturing method thereof

An epitaxial growth and manufacturing method technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems affecting the performance of transistor devices, stacking faults of silicon germanium epitaxial layers, etc., to avoid the formation of pit defects , the effect of increasing hole mobility and improving device performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

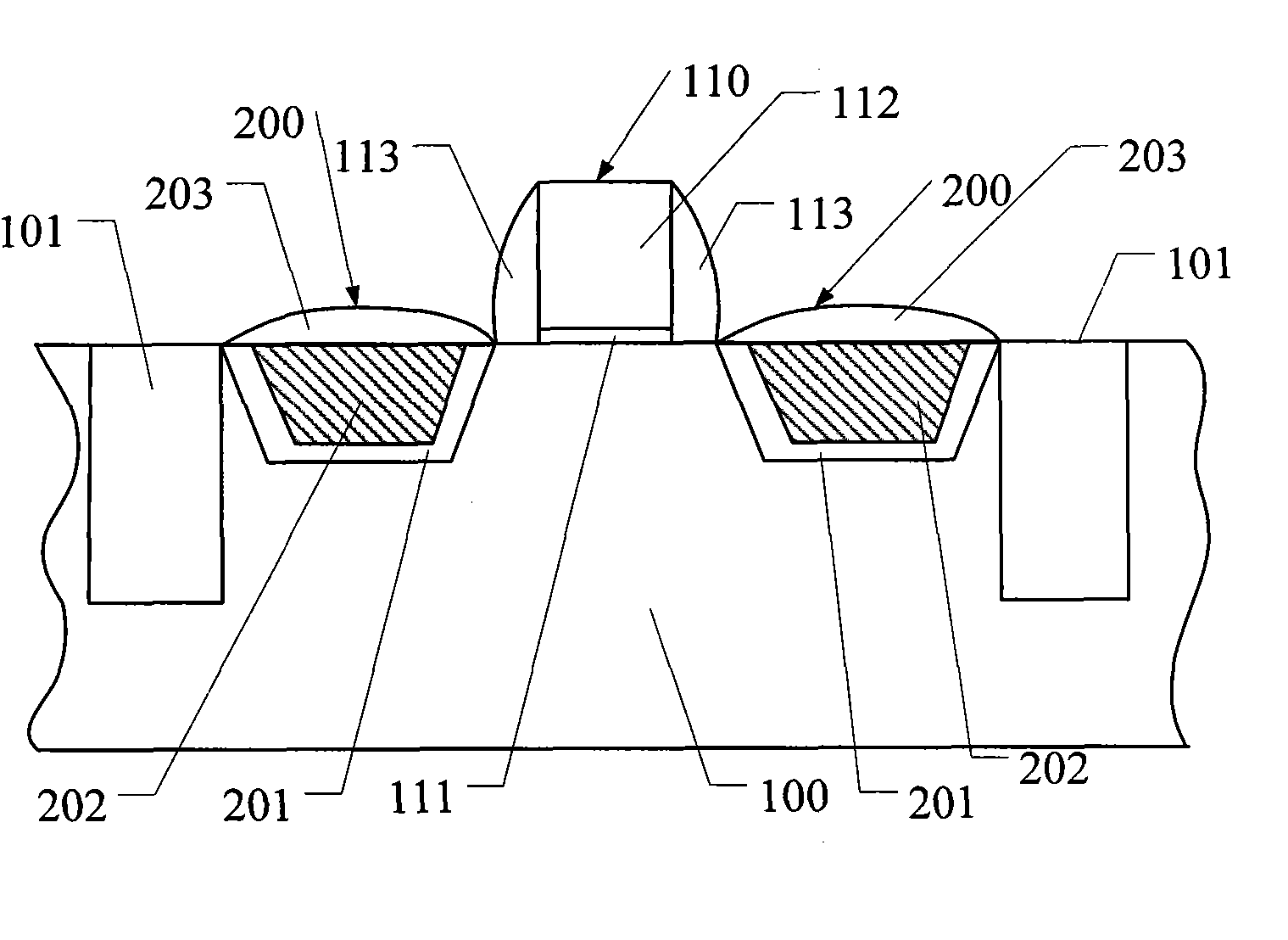

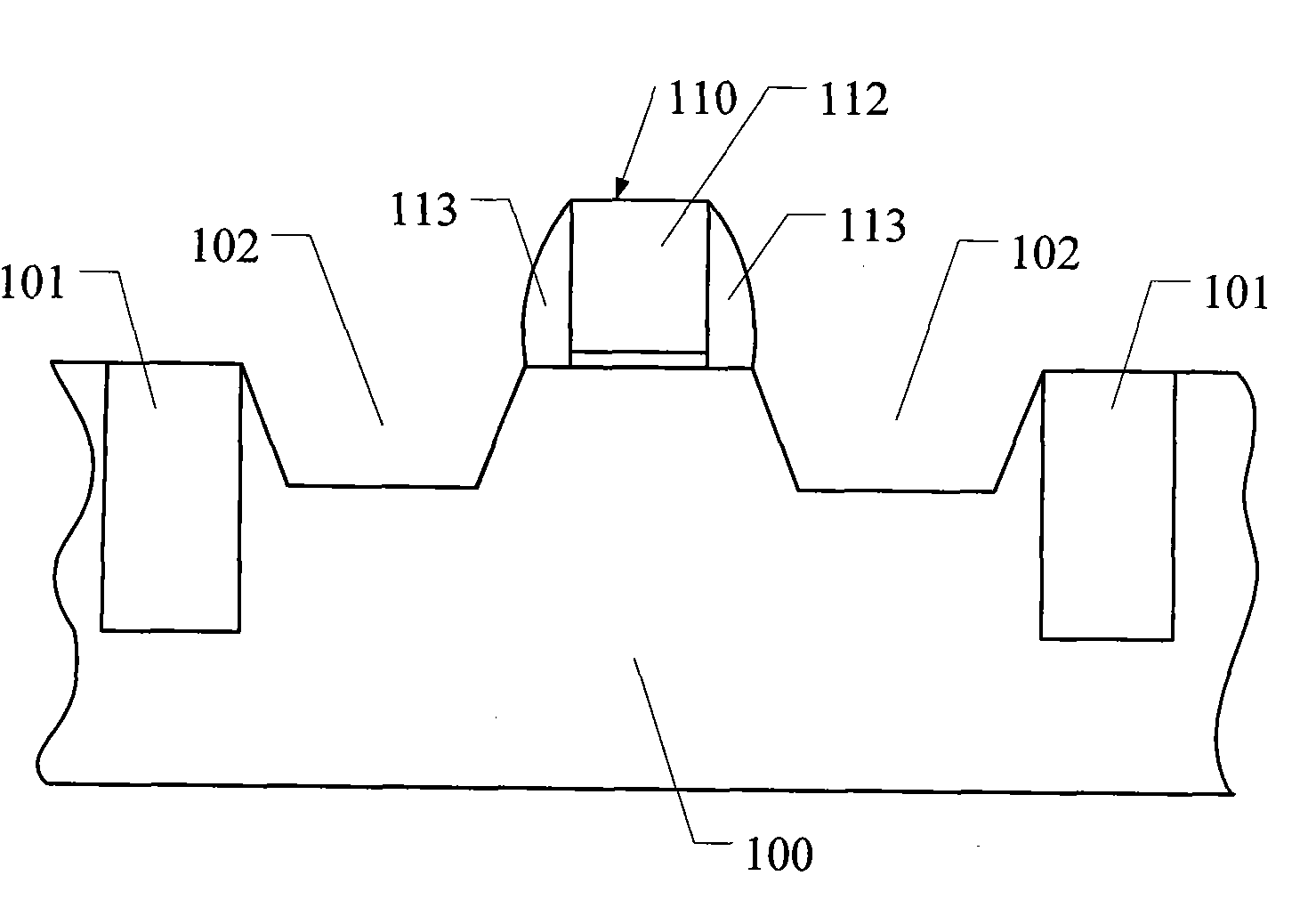

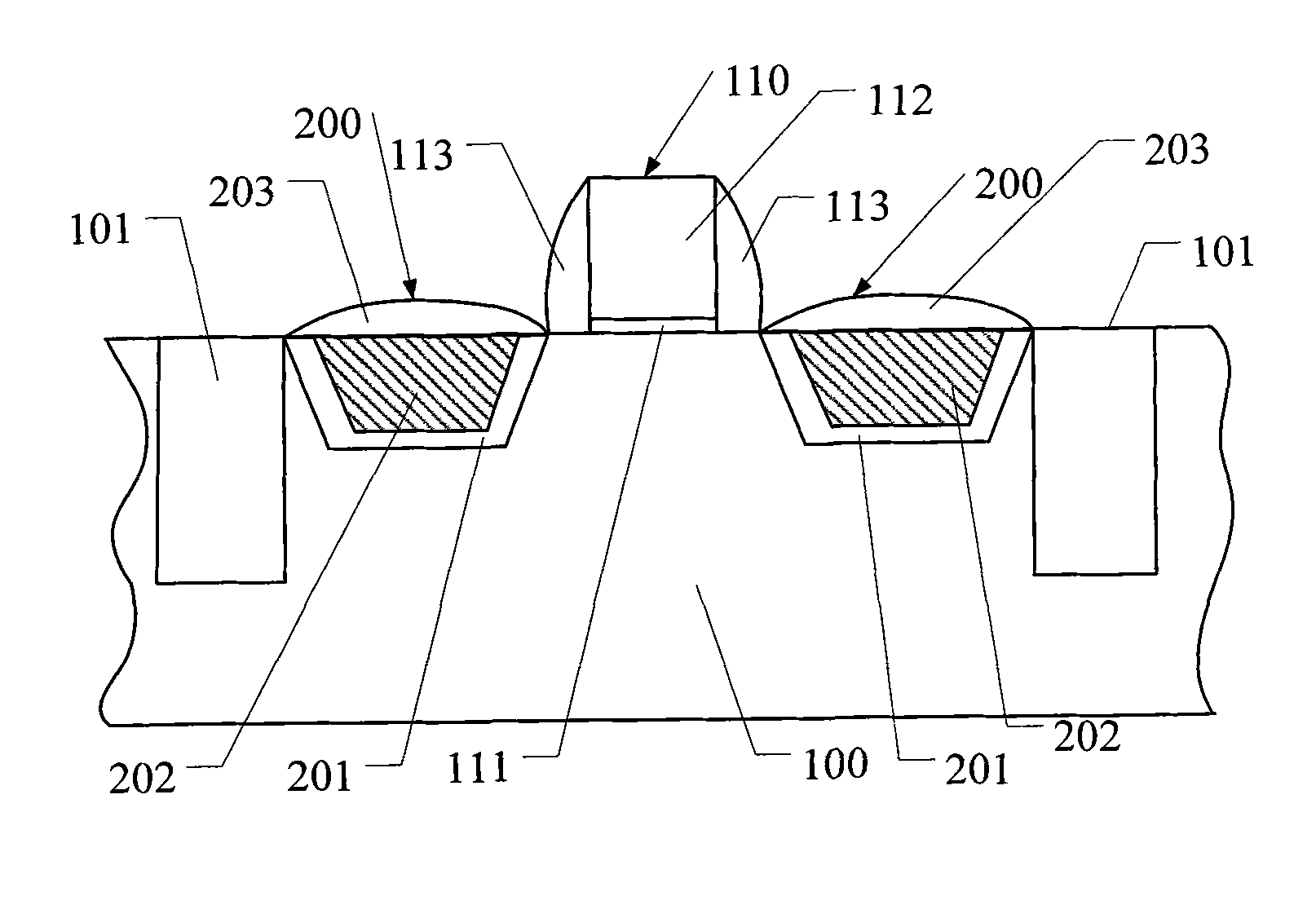

[0036] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0037] A kind of epitaxially grown source / drain region transistor and its manufacturing method described in the present invention can be realized in various alternative ways, and the following is an illustration through a preferred embodiment, of course, the present invention is not limited to this specific embodiment, Common substitutions known to those skilled in the art undoubtedly fall within the protection scope of the present invention.

[0038] Secondly, the present invention is described in detail using schematic diagrams. When describing the embodiments of the present invention in detail, for the sake of illustration, the schematic diagrams are not partially enlarged according to the general scale, which should not be used as a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com