Connector and manufacture method thereof

A manufacturing method and connector technology, which are applied in the connection, the parts of the connection device, the protective grounding/shielding device of the connection parts, etc., can solve the deformation of the conductive terminal, the inner iron shell and the outer iron shell, the low work efficiency, and the assembly process. Complex problems, to achieve the effect of preventing external moisture intrusion, high work efficiency, and simple manufacturing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

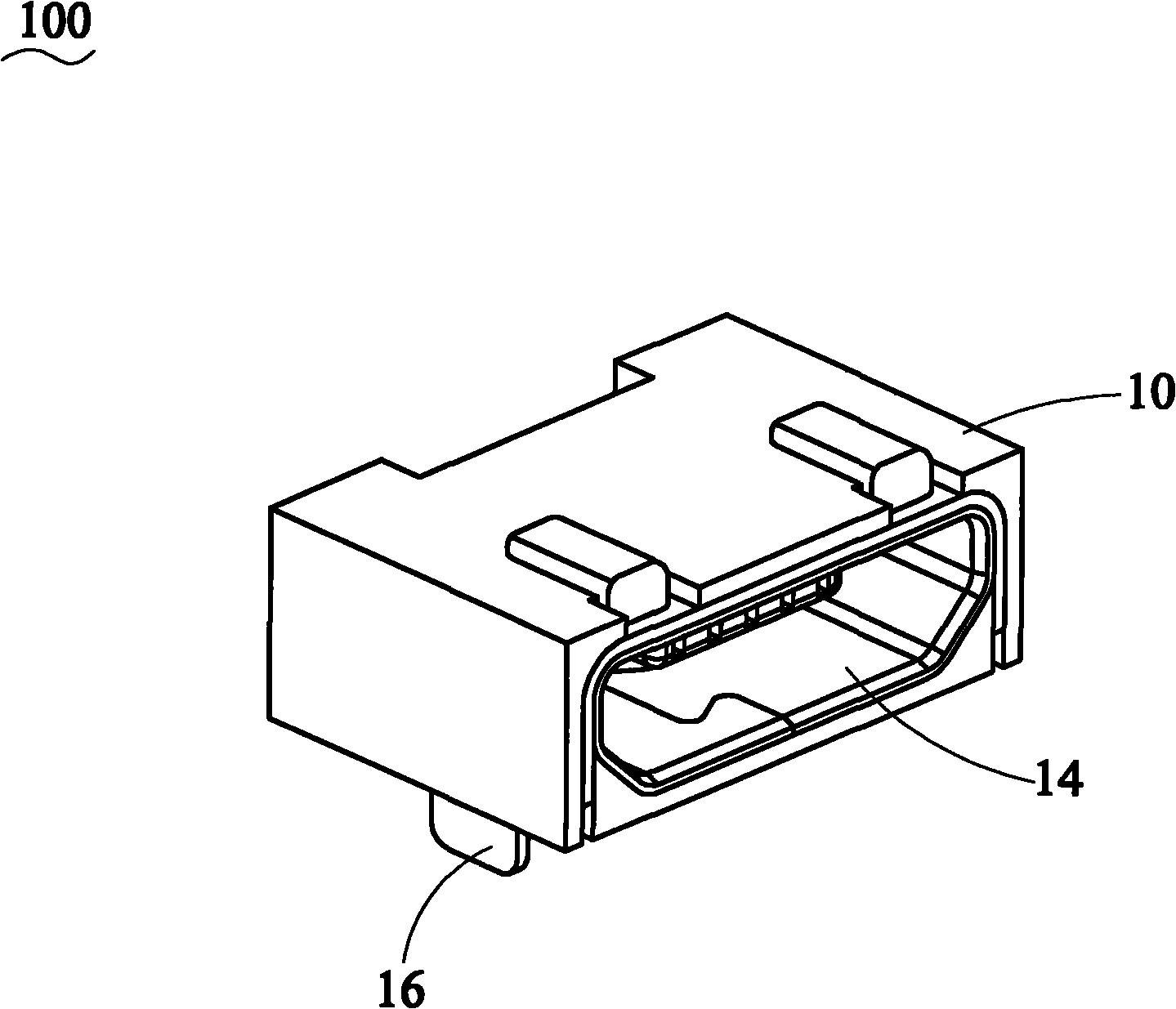

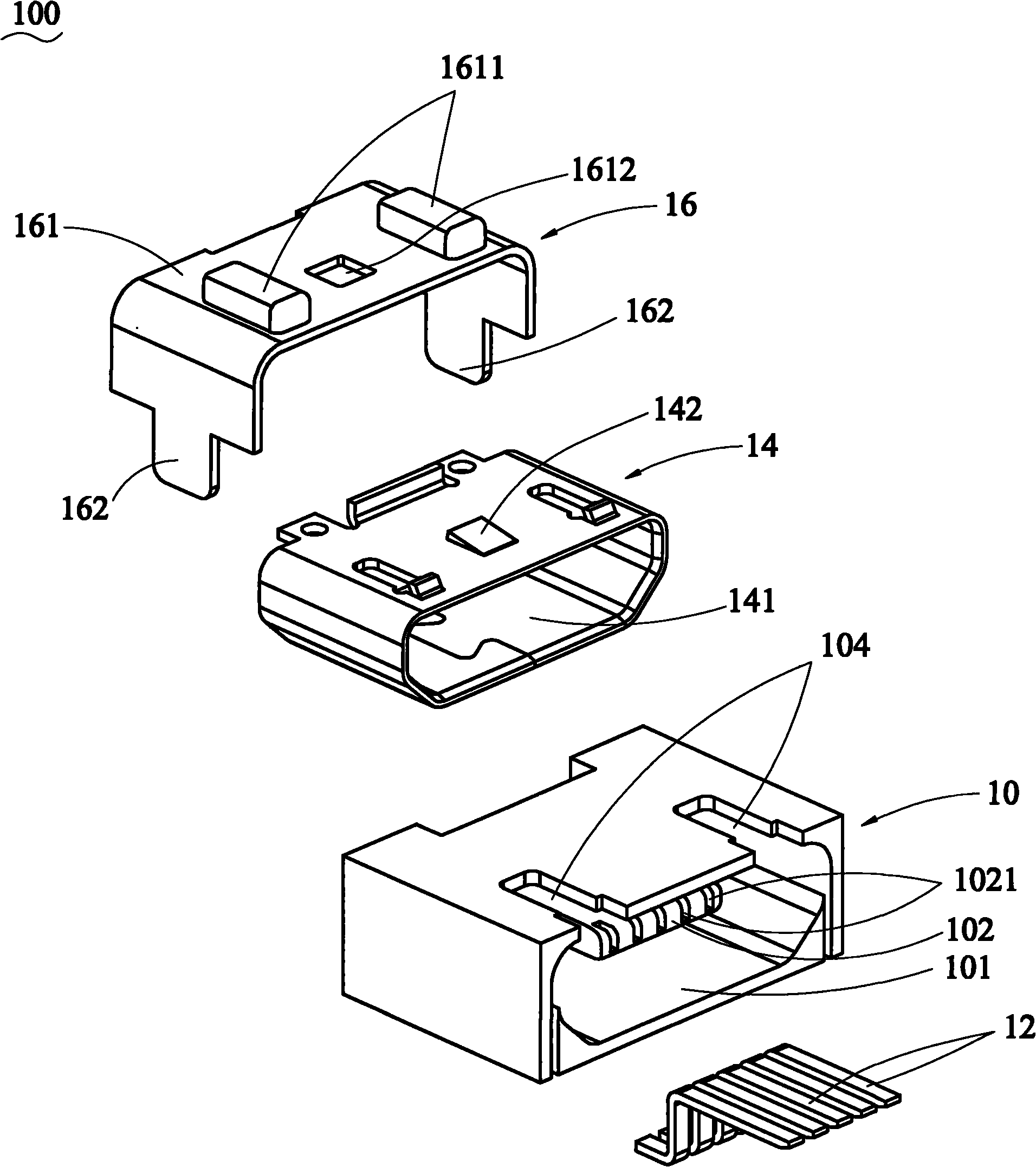

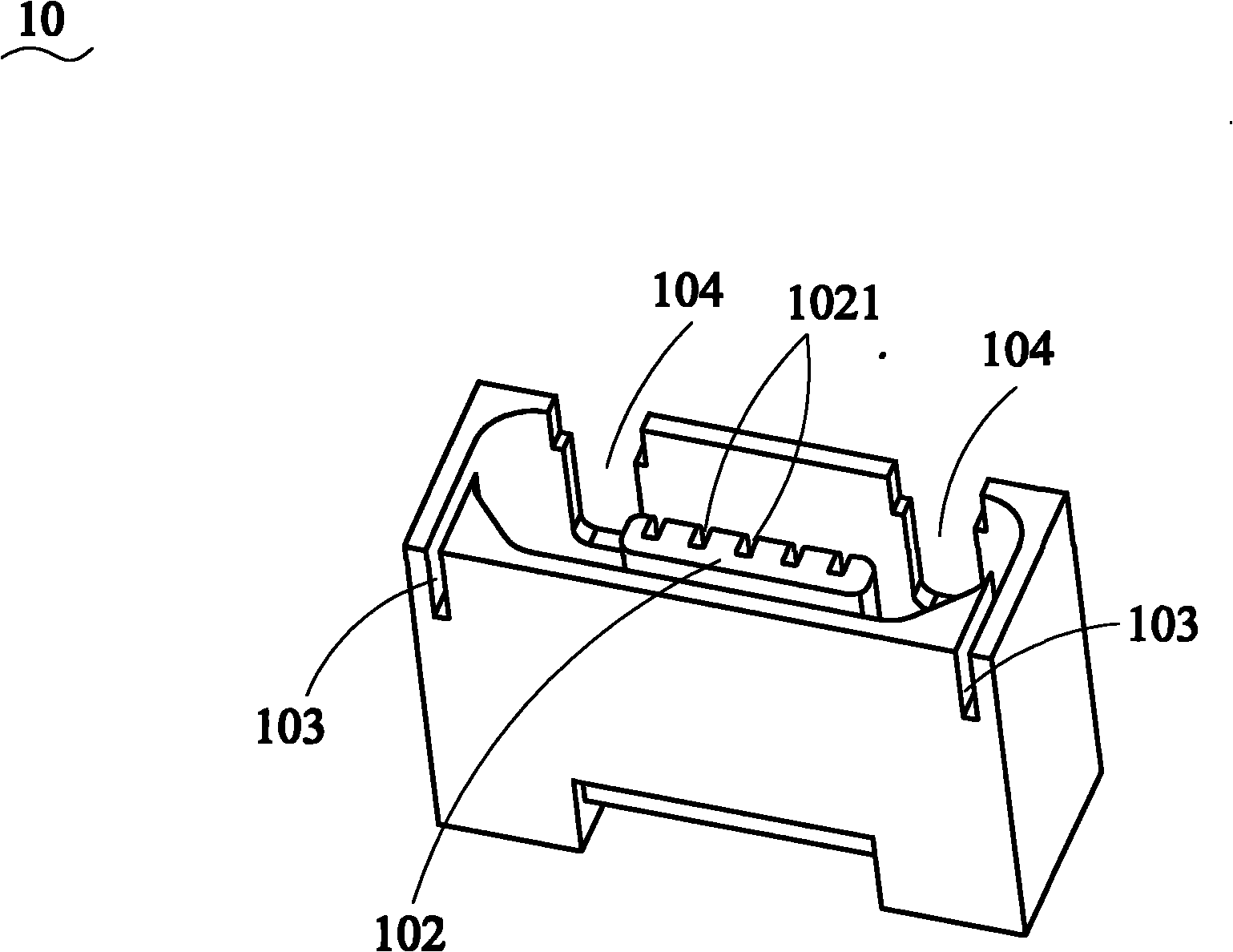

[0022] see figure 1 and figure 2 The connector 100 of the present invention includes an insulating body 10, a conductive terminal 12, a first metal shell 14, and a second metal shell 16, and the second metal shell 16 is fixedly wrapped around the first metal shell 14 and forms a shielding shell (not marked in the figure), the first metal shell 14 has a butt joint groove 141 penetrating through it, the insulating body 10 has an accommodating cavity 101 in a hollow structure, and the insulating body 10 has a protrusion protruding into the The carrying portion 102 in the accommodating cavity 101 and facing the opening of the accommodating cavity 101, the carrying portion 102 protrudes into the pair of connecting grooves 141 and is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com