Chocolate for coating egg roll and preparation method thereof and method for coating chocolate on inner wall of egg roll

A technology of chocolate and egg rolls, applied in the direction of coating preservation, application, cocoa, etc., can solve the problems of uneven spraying, low freezing point, chocolate is not easy to suck out, etc., achieve good fluidity and ensure brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

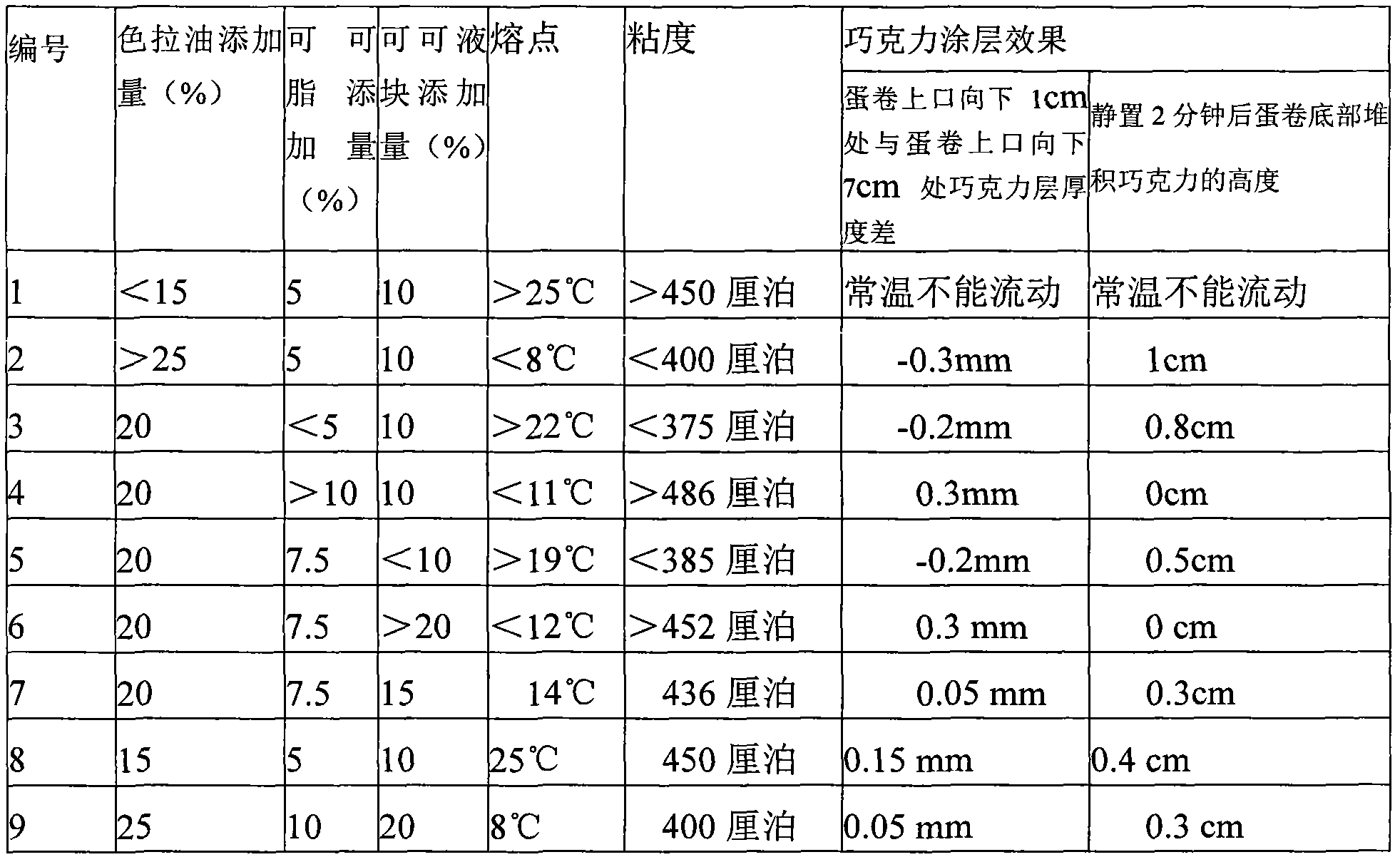

Examples

Embodiment 1

[0031] 1. A method for preparing chocolate for egg roll coating

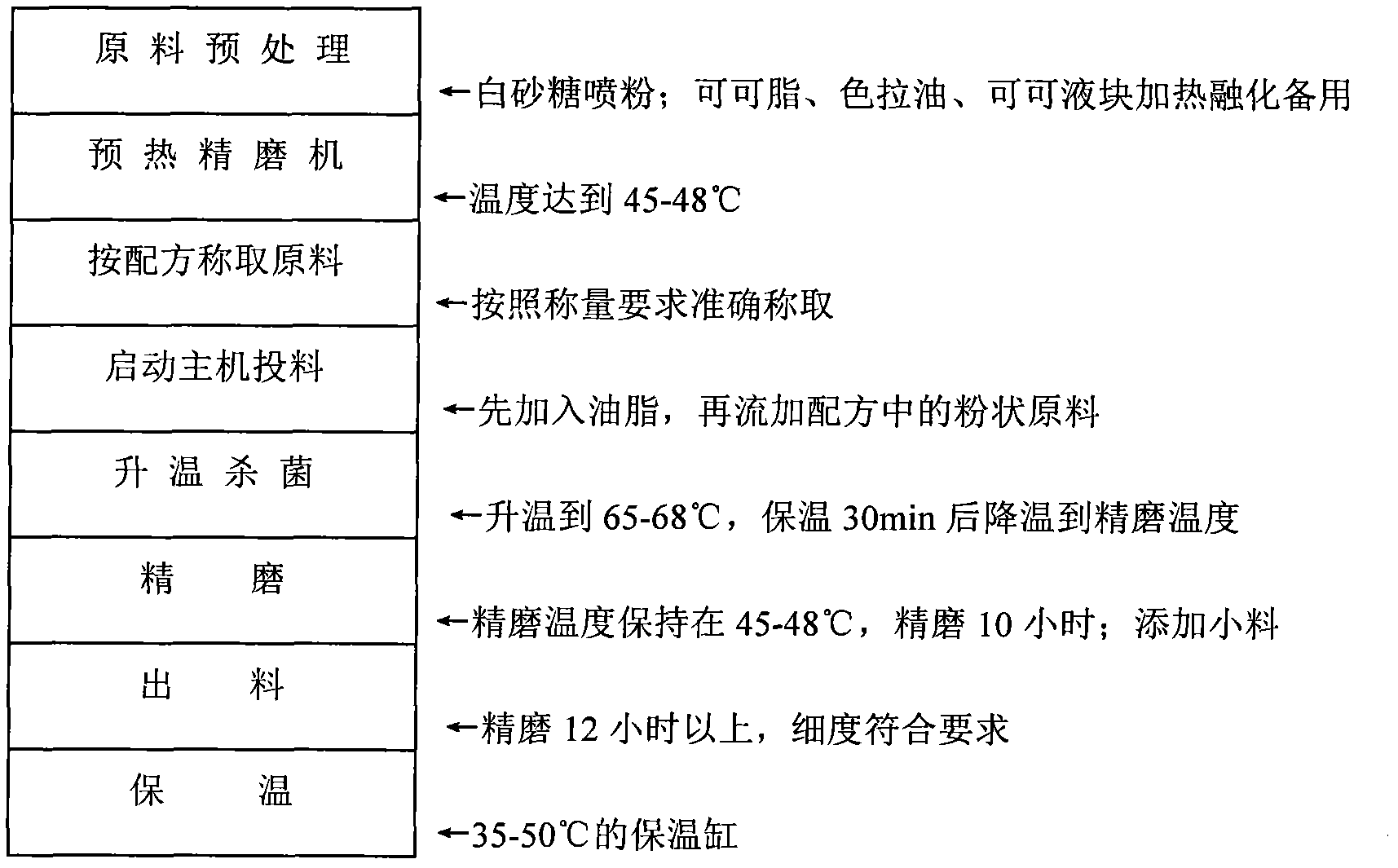

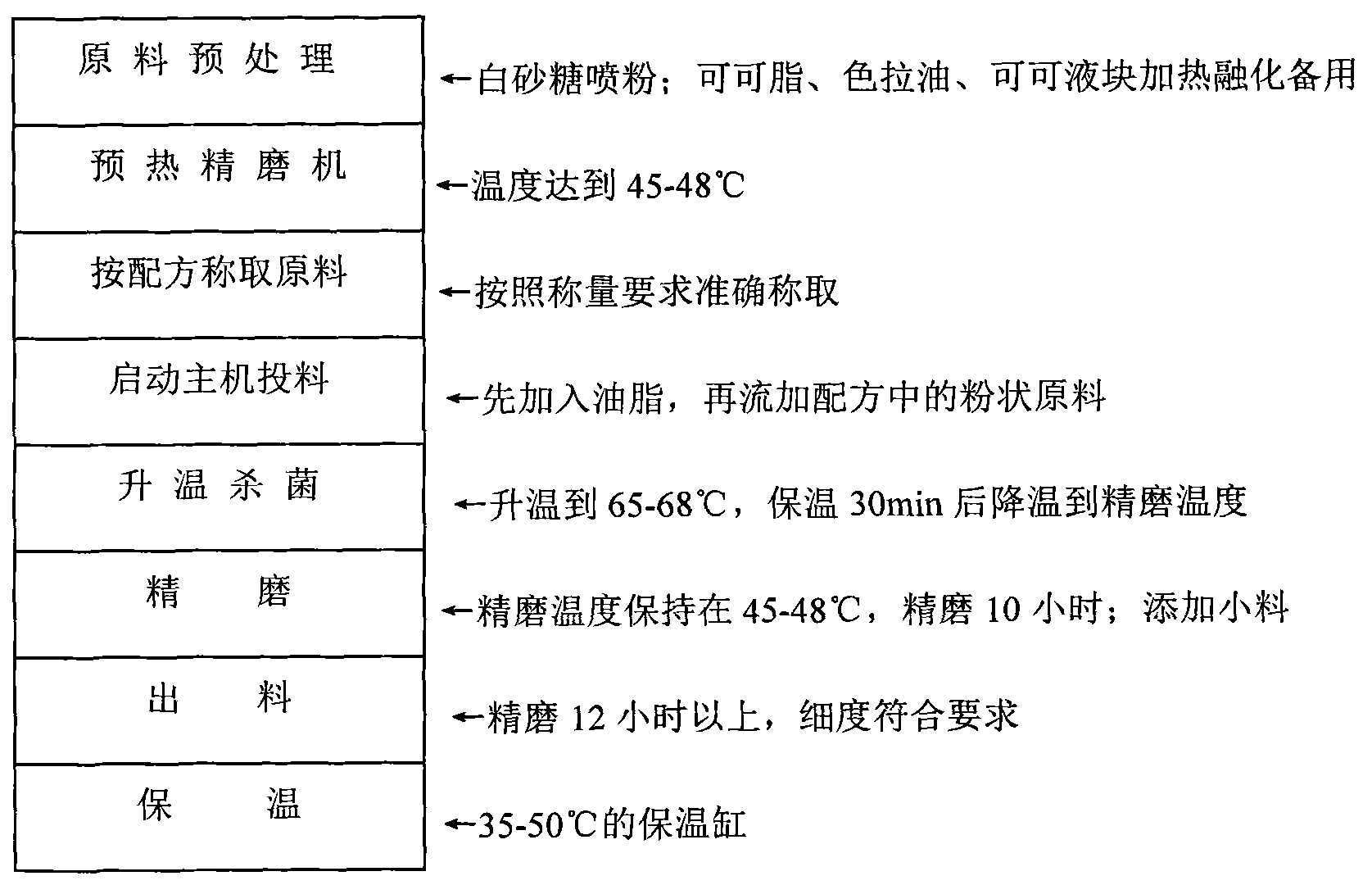

[0032] The method for preparing the chocolate for egg roll coating comprises the following steps:

[0033] 1) Raw material pretreatment: powder the white granulated sugar; heat and melt the cocoa butter, salad oil, and cocoa liquor for later use;

[0034] 2) Preheat the refiner so that its temperature reaches 45-48°C;

[0035] 3) Weigh the raw materials according to the formula;

[0036] 4) Start the main engine to feed, first add liquid oil, and then add the powdery raw materials in the formula;

[0037] 5) Warm up to sterilize, heat up to 65-68°C, keep warm for 30 minutes, cool down to the fine grinding temperature, keep the fine grinding temperature at 45-48°C, and finely grind for 10 hours; add lecithin;

[0038] 6) Fine grinding for more than 12 hours, the fineness meets the requirements, heat preservation, and discharging to obtain the chocolate for egg roll coating of the present invention.

[0039] 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com