Off-axis free surface turning method by actively changing spindle rotating speed

A spindle speed and spindle technology, applied in the direction of automatic control devices, feeding devices, manufacturing tools, etc., can solve problems such as uneven processing surface quality, and achieve the effect of uniform processing surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

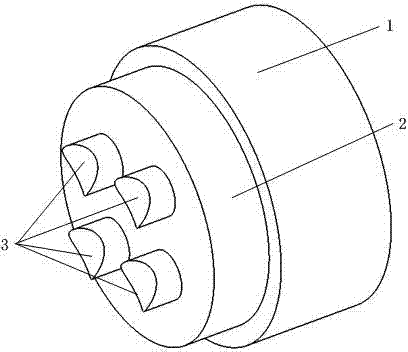

[0029] figure 1 A schematic diagram of the off-axis arrangement of two or more free-form surface workpieces 3 on the fixture positioning reference plane 2 is shown. by figure 1 It can be seen that in the circumferential direction coaxial with the center of rotation of the spindle 1, two or more workpieces are installed on the fixture at equal intervals, figure 1 Take 4 workpieces as an example to ensure the inertia balance of two or more workpieces during the rotation of the spindle, and make the minimum radius of gyration of the diamond tool contact point on the free-form surface deviate from the center of rotation of the spindle.

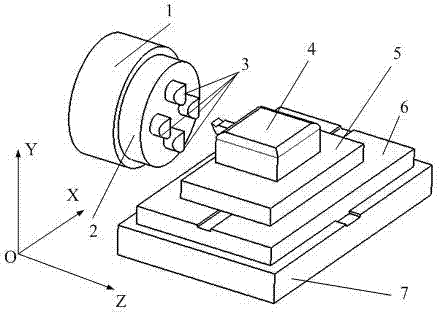

[0030] figure 2 It shows the machining movement required for off-axis turning to create a free-form surface. For free-form surface workpieces, whether it is installed coaxially or off-axis, it is difficult to eliminate the non-rotational symmetry of the surface to be processed, which makes the tool must perform rapid reciprocating motion on the X ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com