Cement mortar for constructional engineering

A cement mortar and construction engineering technology, applied in the field of construction engineering materials, can solve the problems of peeling, bulging and surface cracking of the plastering layer, and achieve the effect of reducing the drying shrinkage value

Inactive Publication Date: 2011-06-29

NANJING EFFUL

View PDF3 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

When such plastering mortar is used on new wall materials, surface cracking and swelling will also occur, and in severe cases, the plastering layer will peel off

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

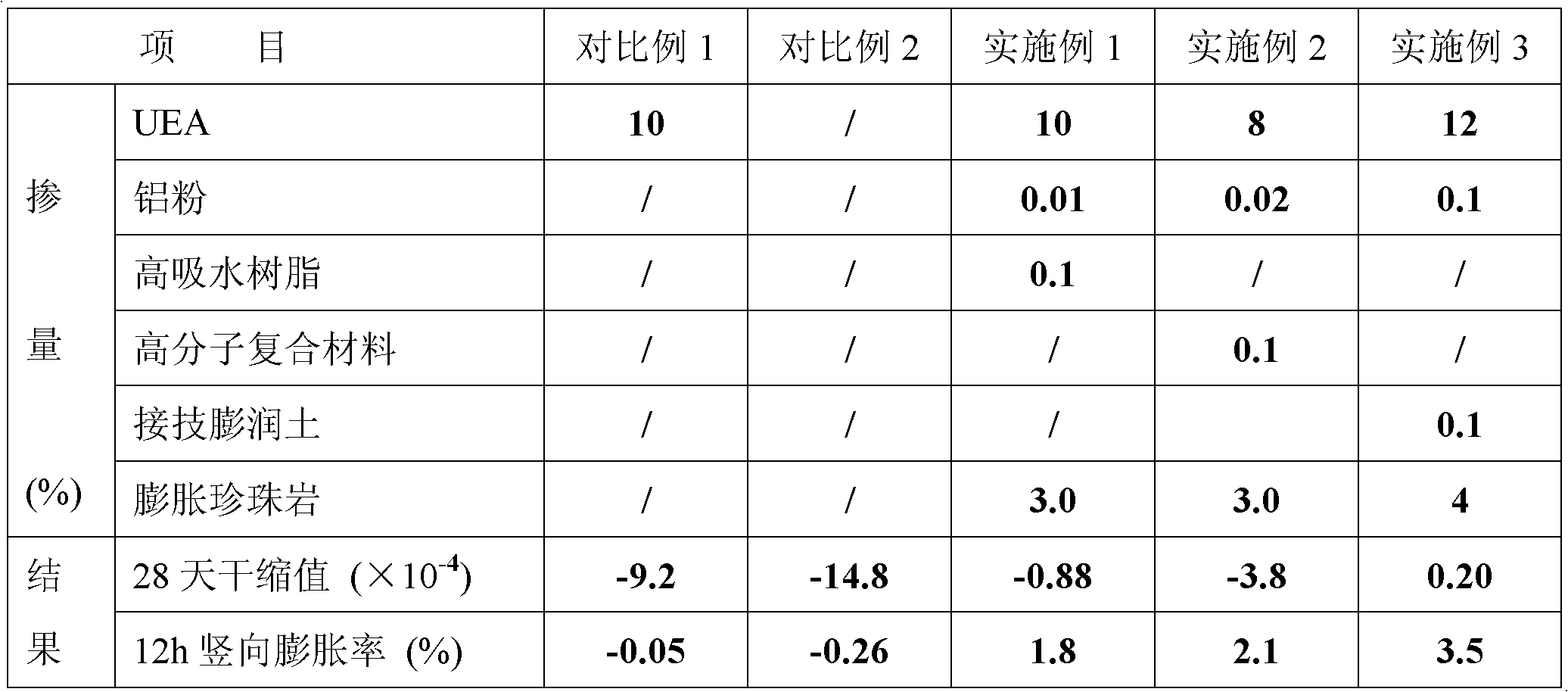

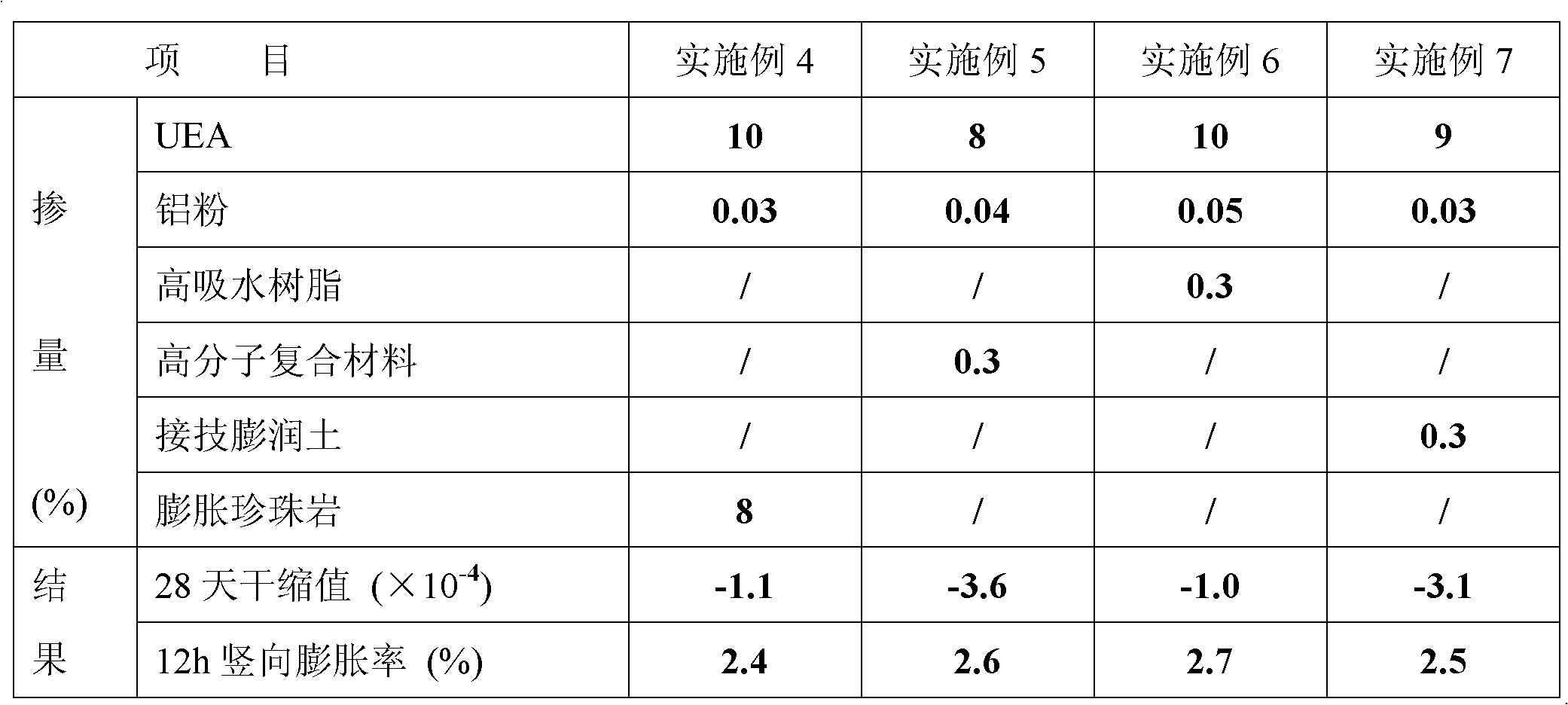

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a cement mortar for constructional engineering. The cement mortar comprises a cement, yellow ground, a water-retaining and thickening agent, a plastic swelling agent, a concrete swelling agent and an internal curing agent. Because the plastic swelling agent forms a large amount of fine and uniform bubbles in the mortar, the plastic mortar swells; after the internal curing agent is mixed, innumberable mini-impounding reservoirs are built in the cement mortar; and when the mortar is in lack of water, the water in the internal curing agent can be slowly released so as to ensure the concrete and the swelling agent to continuously hydrate until the water is used up. Thus, long hydration time is provided for the swelling agent, and more swell crystal ettringites are generated, thereby reducing the dry shrinkage value of the cement mortar.

Description

A kind of cement mortar for construction engineering technical field The invention relates to a construction engineering material, in particular to a cement mortar for construction engineering with early plastic expansion properties and a small later drying shrinkage value. Background technique Cement plastering mortar is an indispensable engineering material for building walls. After years of innovation in wall materials, major successes have been achieved. The production and use of clay bricks have been restricted nationwide, and a large number of new wall materials have emerged, such as autoclaved aerated concrete blocks, small concrete hollow blocks, and various lightweight slats. These wall materials have different properties and put forward higher requirements for masonry mortar. For example, the water absorption rate of the autoclaved aerated concrete block is very high, and the water in the masonry mortar is quickly absorbed, and the mortar shrinks greatly. Howev...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B38/02C04B28/00

CPCC04B28/02C04B18/02

Inventor 唐绍林汤淑平万建东肖启明徐红英刘丽娟王彦梅唐修仁

Owner NANJING EFFUL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com