Method for preparing iron ion immobilization affinity chromatography monolith column

A technology of iron ion and monolithic column, which is applied in the field of immobilized affinity chromatography monolithic column, which can solve the problem of poor reproducibility of immobilized metal ion affinity chromatography monolithic column preparation, unstable performance of affinity chromatography monolithic column, and long chemical modification time and other problems, to achieve the effect of less steps, simple preparation method and fast mass transfer rate

Active Publication Date: 2011-06-29

DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

View PDF1 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The purpose of the present invention is to provide a method for preparing an iron ion-immobilized affinity chromatography monolithic column, in order to solve the problem of long chemical modification time, cumbersome operation process and the problem of immobilized metal ion affini

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

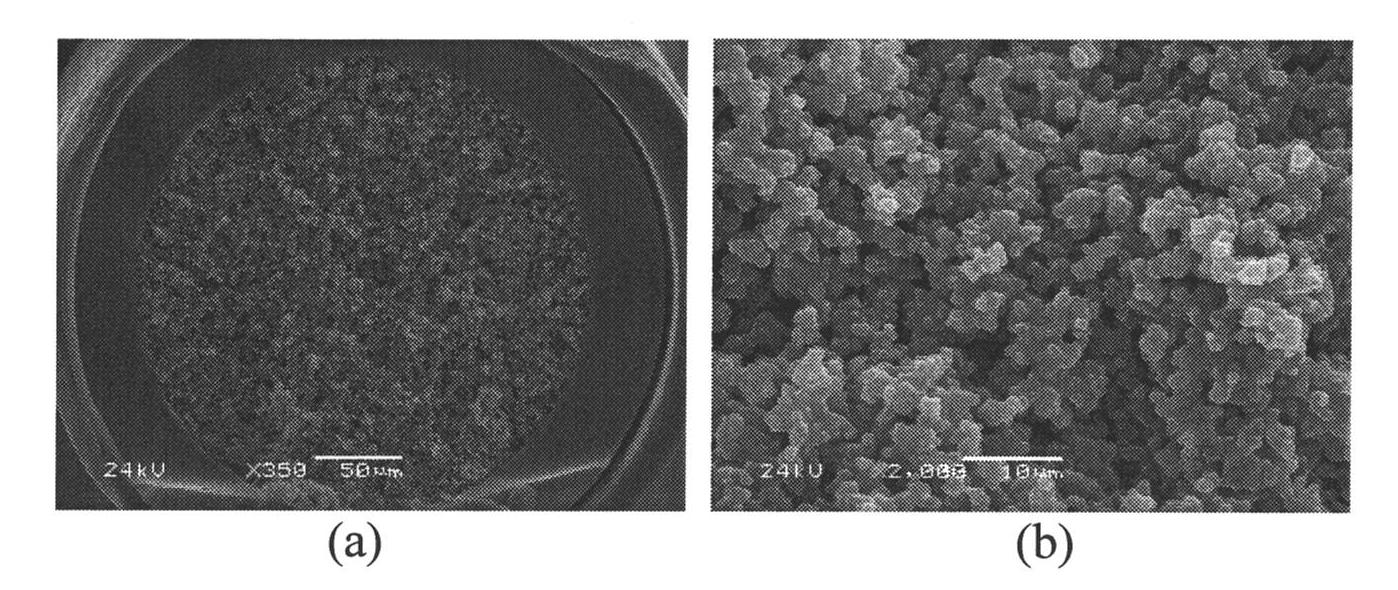

The invention relates to a method for preparing an iron ion immobilization affinity chromatography monolith column, which comprises: preparing porous monolith column substrate by polymerization in capillaries with N-hydroxysuccinimide serving as a functional monomer, ethanedimethylethyl acrylate as a crosslinking agent, mixture of cyclohexanol, dodecanol and N,N-dimethylformamide as a porogen andazodiisobutyronitrile as an initiator; bonding carboxyl-containing functional groups on the surface of the monolith column substrate through surface modification for subsequent iron ion immobilization; and immobilizing iron ions by using iron ion containing solution to accomplish the preparation of the iron ion immobilization affinity chromatography monolith column. The invention has the advantages that: the preparation method is simple and convenient; and the micro structure of the obtained substrate material is uniform. Compared with other metal ion immobilization affinity chromatography monolith column, the iron ion immobilization affinity chromatography monolith column prepared by the method has high preparation repeatability, and has stable performance and high specific enriching capacity for phosphorylated peptide fragments.

Description

Technical field [0001] The invention relates to an immobilized affinity chromatographic monolithic column for the selective enrichment and separation of online or offline phosphorylated peptides, in particular to the preparation of an iron ion immobilized affinity chromatographic monolithic column. Background technique [0002] Protein phosphorylation is one of the most common post-translational modifications, and it plays an important role in signal transduction, metabolic regulation, and cell function regulation during life. However, phosphorylated proteins / peptides are usually low in content and are often interfered by a large number of non-phosphorylated proteins / peptides in mass spectrometry analysis. Therefore, the development of selective enrichment techniques for phosphorylated peptides is essential for in-depth research on phosphorylated proteome. [0003] Immobilized metal affinity chromatography based on the specific interaction between immobilized metal ions and phosph...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C07K1/22B01J20/286

Inventor 张丽华张丽媛王晖梁振张玉奎

Owner DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com