Environment-friendly halogen-free inflaming retarding adhesive tape and production process thereof

A flame-retardant adhesive tape and production process technology, applied in the field of environmentally friendly halogen-free flame-retardant adhesive tape and its production process, can solve the problems of threatening human health, polluting the environment, and the non-recyclable use of flame-retardant adhesives/adhesive tapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

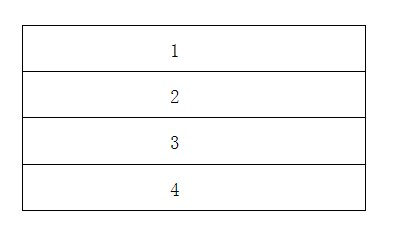

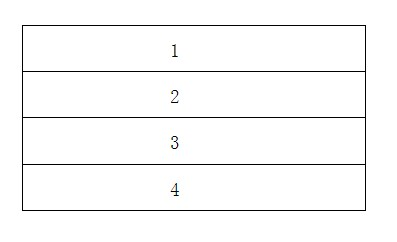

[0024] This embodiment is an environmentally friendly halogen-free flame-retardant adhesive tape with a layered structure such as figure 1 As shown, from top to bottom: halogen-free flame-retardant adhesive layer 1, tissue paper layer 2, halogen-free flame-retardant adhesive layer 3 and double-silicon release paper layer 4; halogen-free flame-retardant adhesive consists of the following groups by weight percentage Composition: 56% mixture of acrylate copolymer, adhesive, tackifying resin and flame retardant, 26% ethyl acetate, 18% toluene.

[0025] In the mixture of acrylate copolymer, adhesive, tackifying resin and flame retardant, the weight percentage of each component is: acrylate copolymer 35%, adhesive 50%, tackifying resin 5%, flame retardant 10% .

[0026] The production process of environmentally friendly halogen-free flame-retardant tape is carried out according to the following steps:

[0027] (1) Mix acrylate copolymer, adhesive, tackifying resin and flame retard...

Embodiment 2

[0036] This embodiment is an environmentally friendly halogen-free flame-retardant adhesive tape with a layered structure such as figure 1 As shown, from top to bottom: halogen-free flame-retardant adhesive layer 1, tissue paper layer 2, halogen-free flame-retardant adhesive layer 3 and double-silicon release paper layer 4; halogen-free flame-retardant adhesive consists of the following groups by weight percentage Composition: 50% mixture of acrylate copolymer, adhesive, tackifying resin and flame retardant, 30% ethyl acetate, 20% toluene.

[0037] In the mixture of acrylate copolymer, adhesive, tackifying resin and flame retardant, the weight percentage of each component is: acrylate copolymer 55%, adhesive 30%, tackifying resin 10%, flame retardant 5% .

[0038] The production process of environmentally friendly halogen-free flame-retardant tape is carried out according to the following steps:

[0039] (1) Mix acrylate copolymer, adhesive, tackifying resin and flame retard...

Embodiment 3

[0048] This embodiment is an environmentally friendly halogen-free flame-retardant adhesive tape with a layered structure such as figure 1 As shown, from top to bottom: halogen-free flame-retardant adhesive layer 1, tissue paper layer 2, halogen-free flame-retardant adhesive layer 3 and double-silicon release paper layer 4; halogen-free flame-retardant adhesive consists of the following groups by weight percentage Composition: 60% mixture of acrylate copolymer, adhesive, tackifying resin and flame retardant, 25% ethyl acetate, 15% toluene.

[0049] In the mixture of acrylate copolymer, adhesive, tackifying resin and flame retardant, the weight percentages of each component are: 38% of acrylate copolymer, 32% of adhesive, 15% of tackifying resin, and 15% of flame retardant .

[0050] The production process of environmentally friendly halogen-free flame-retardant tape is carried out according to the following steps:

[0051] (1) Mix acrylate copolymer, adhesive, tackifying res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com