Special connecting and fixing construction member for constructing wall surface of stone panel

A technology of stone slabs and slabs, applied in building construction, construction, covering/lining, etc., can solve problems such as pushing up construction costs, reducing strength, increasing weight and handling costs, reducing overall construction costs and improving image. And word of mouth, with the effect of market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

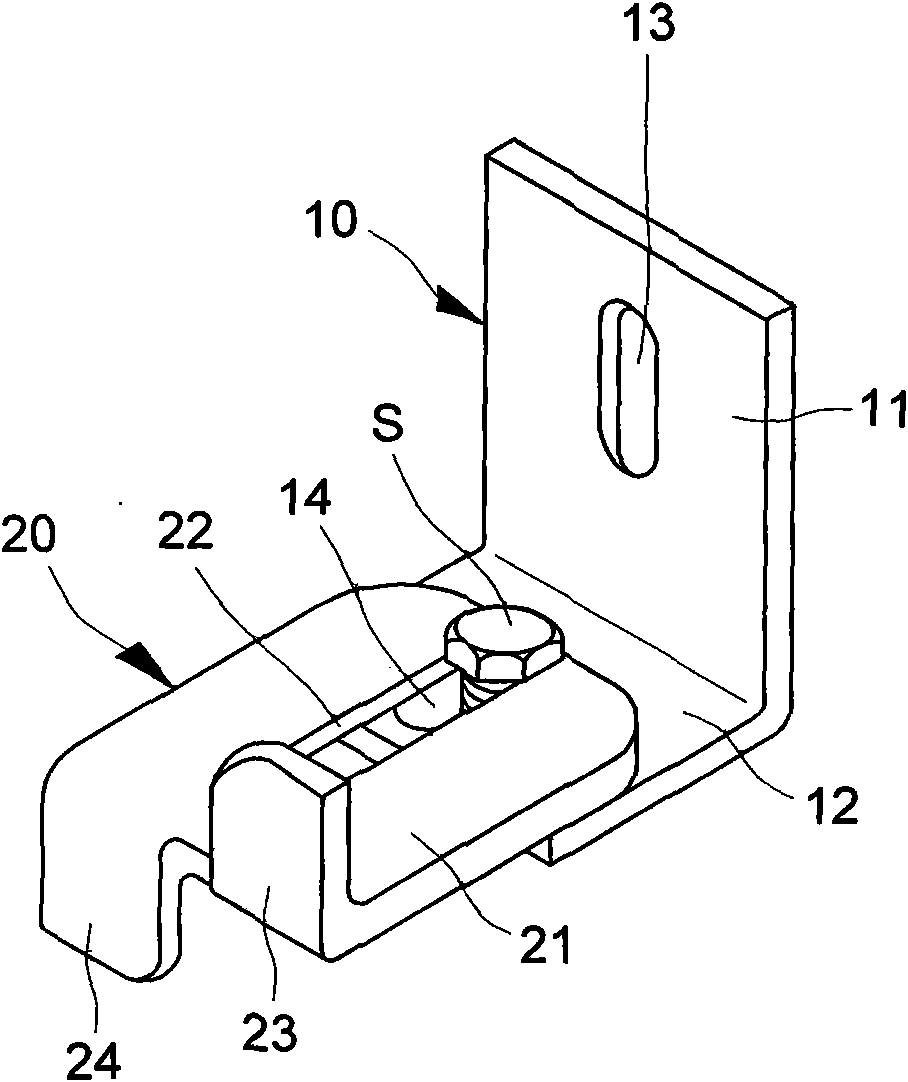

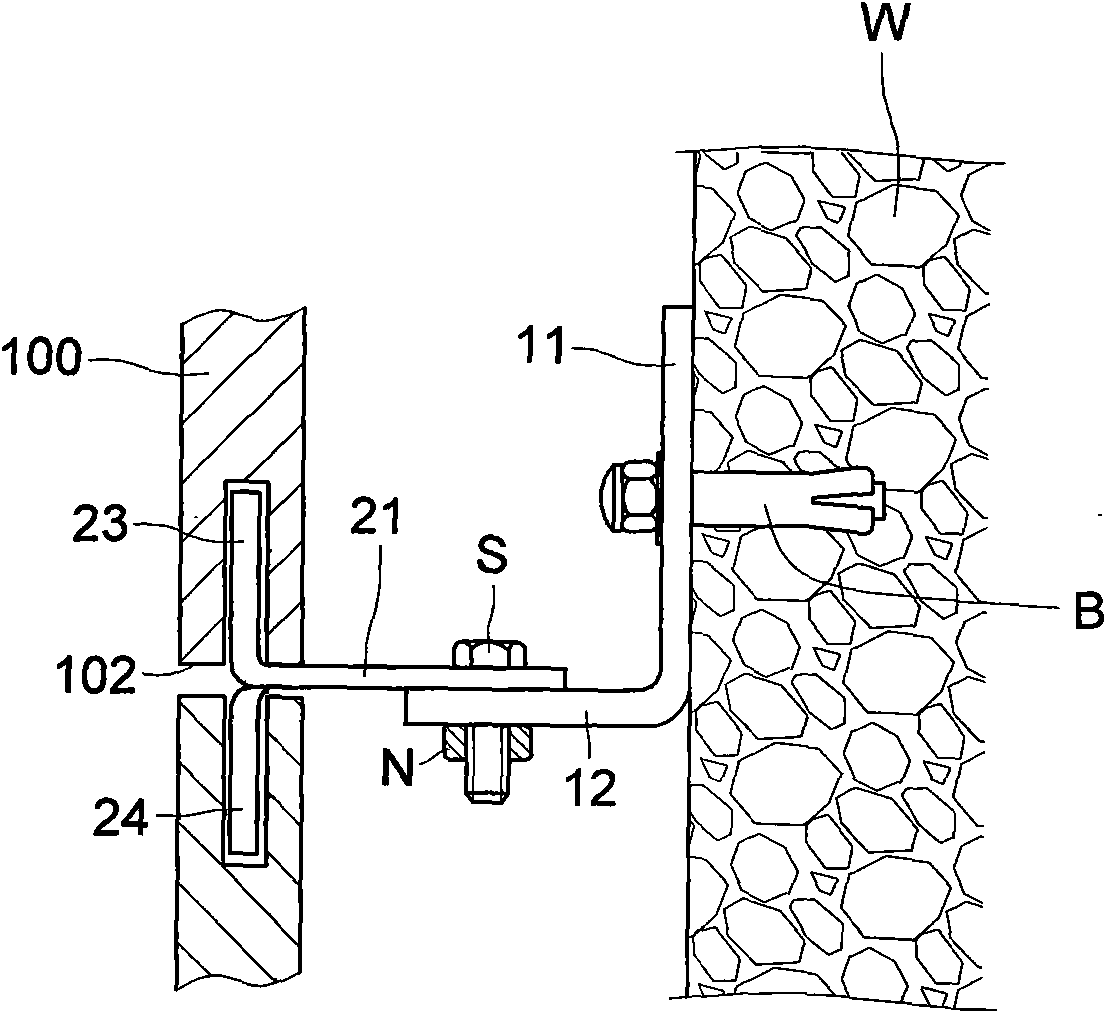

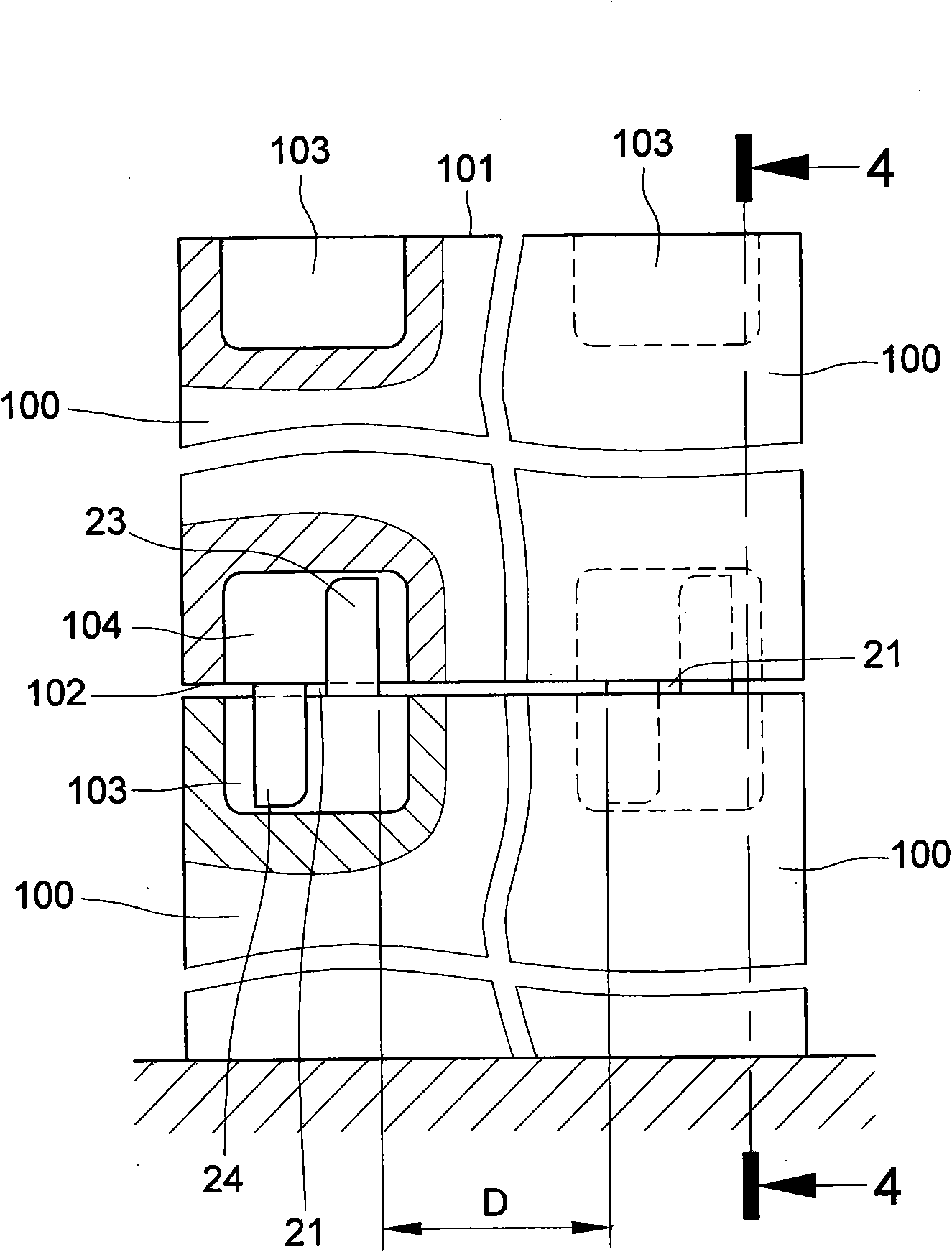

[0073] see Figure 9 to Figure 11 Shown, the present invention builds the special fastening component of stone slab wall surface, comprises:

[0074] An insert body 50 is formed by stamping and bending a long metal plate twice, and has an upper plate surface 51, a lower plate surface 52 and a middle plate surface 53, wherein the upper plate surface 51 and the lower plate surface 52 The middle plate surfaces 53 are connected by punching and bending to form parallel opposite sides up and down, and there is a distance d1 between the plate surfaces on the same side (such as Figure 10 As shown), in addition, a fixing hole 54 is perforated in the center of the upper plate surface 51, and a positioning foot 55 parallel to the upper plate surface 51 is protruded outward at the center of the free end edge surface of the lower plate surface 52;

[0075] A receiving seat 60 is formed by stamping and bending a long metal plate once, and has a horizontal plate surface 61 and a vertical p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com