Film bulk acoustic resonator (FBAR)-based wireless micro quality sensor network node

A thin-film bulk acoustic wave and mass sensor technology, which is applied in the field of mass sensors and wireless micro-mass sensor network nodes, can solve the problems of large structural mutual interference, limited measurement range, and lack of versatility of the three-mixing method, and achieve wide-range real-time Effects of measurement, ensuring measurement sensitivity, and improving measurement sensitivity and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

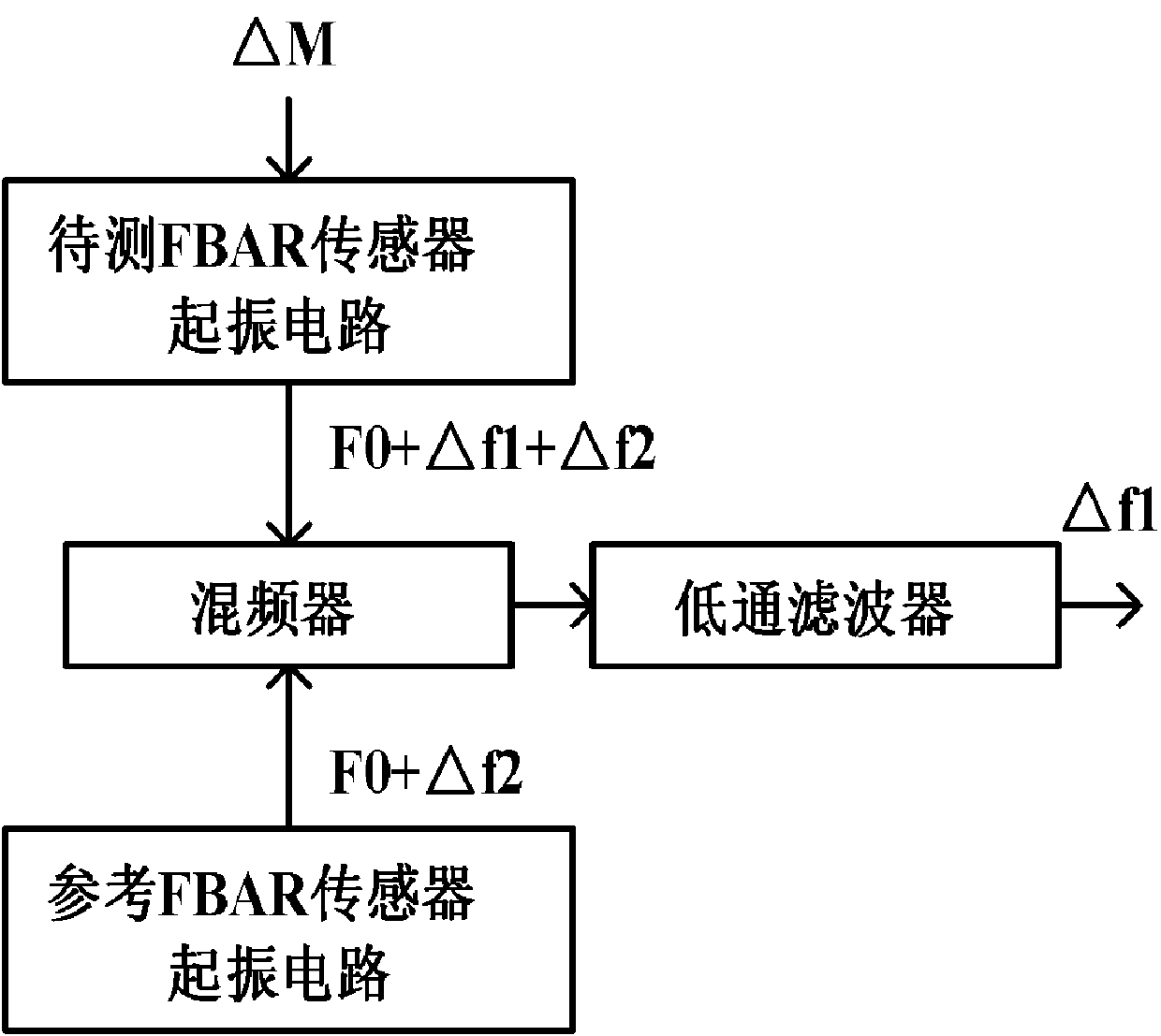

[0070] see figure 1 .

[0071] Thin film bulk acoustic resonator sensor oscillating circuit to be tested: the sensor circuit, used to convert the micro-mass signal to be measured into a radio frequency signal through the thin film bulk acoustic resonator sensor oscillating circuit.

[0072] Reference thin film bulk acoustic resonator sensor oscillation circuit: that is, the sensor circuit, which is used to convert the reference micro-mass signal into a radio frequency signal through the thin film bulk acoustic resonator sensor oscillation circuit.

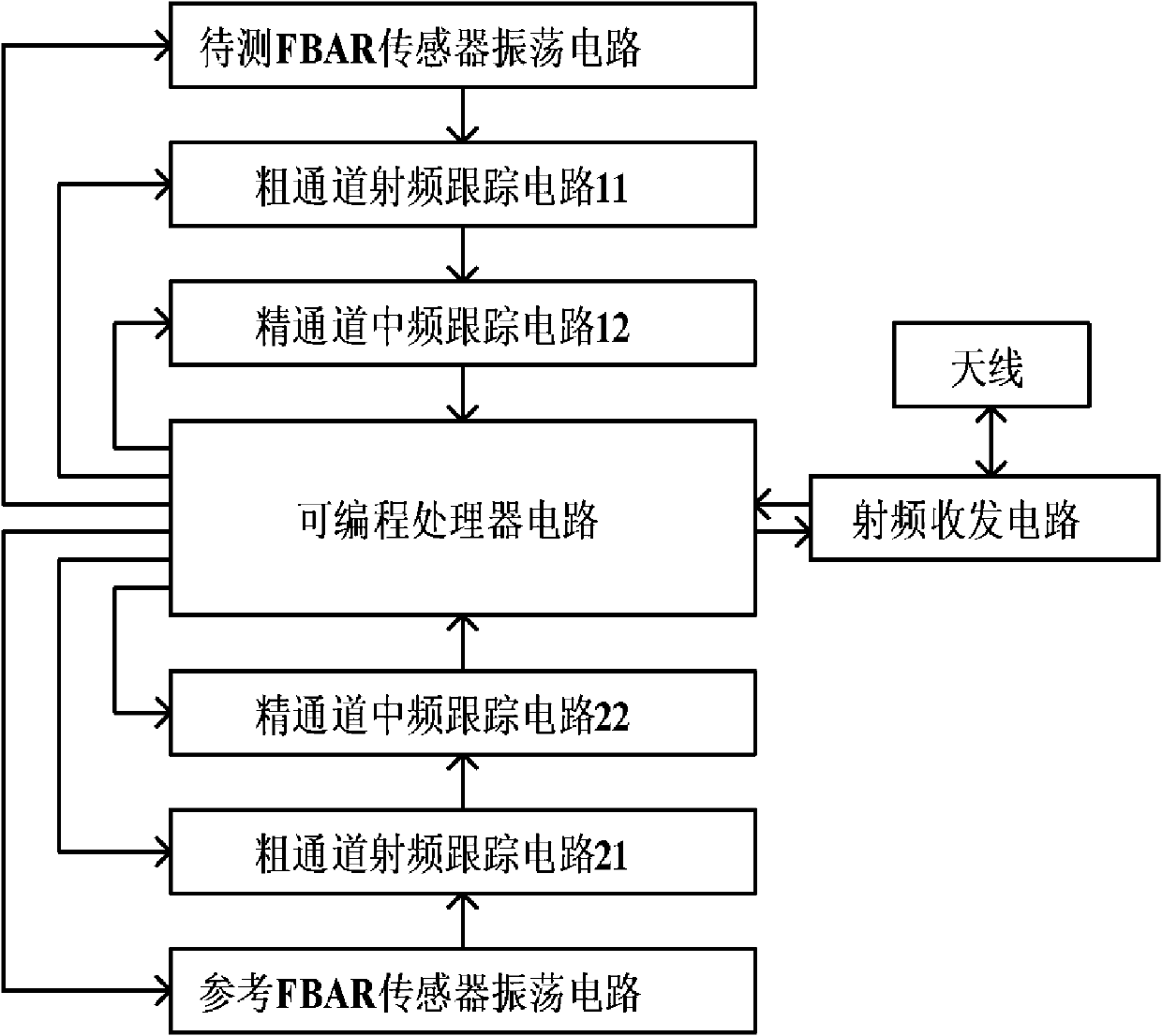

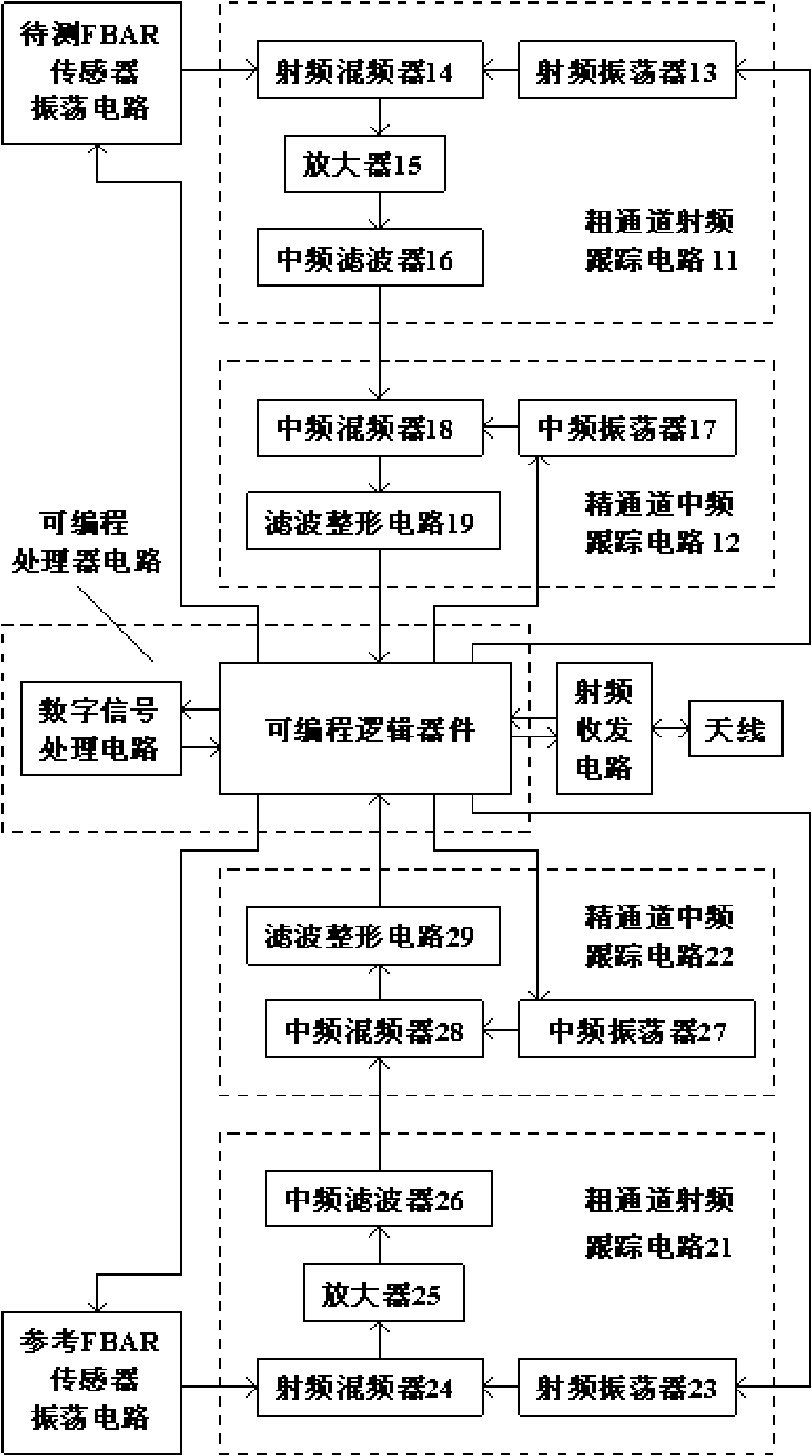

[0073] Coarse channel RF tracking circuit: used to convert the RF signal into an intermediate frequency signal, and dynamically modify the frequency setting parameters of the oscillation circuit according to the instructions of the programmable processor circuit, and track the frequency of the RF signal to realize wireless based on thin film bulk acoustic resonator Broadband range for tiny mass sensor network nodes.

[0074] Fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com