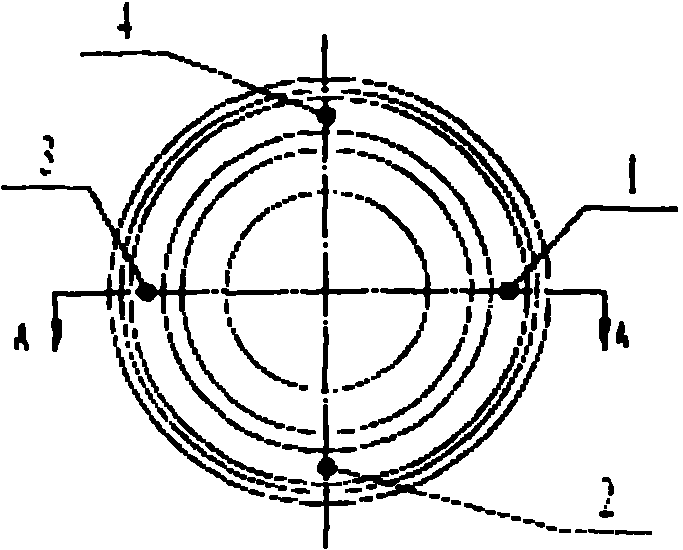

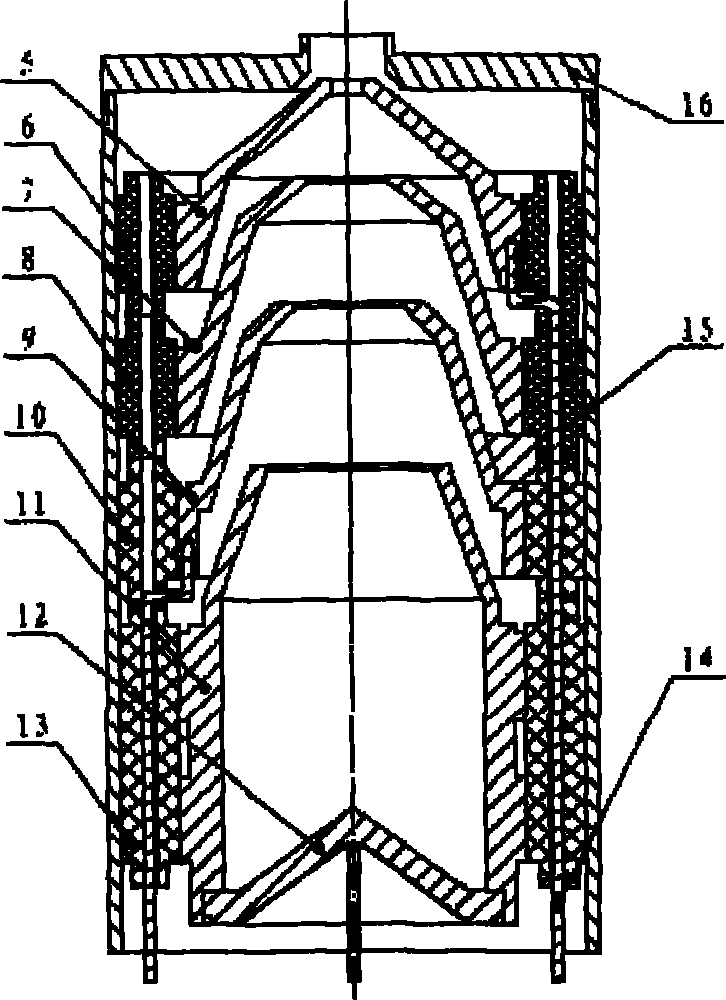

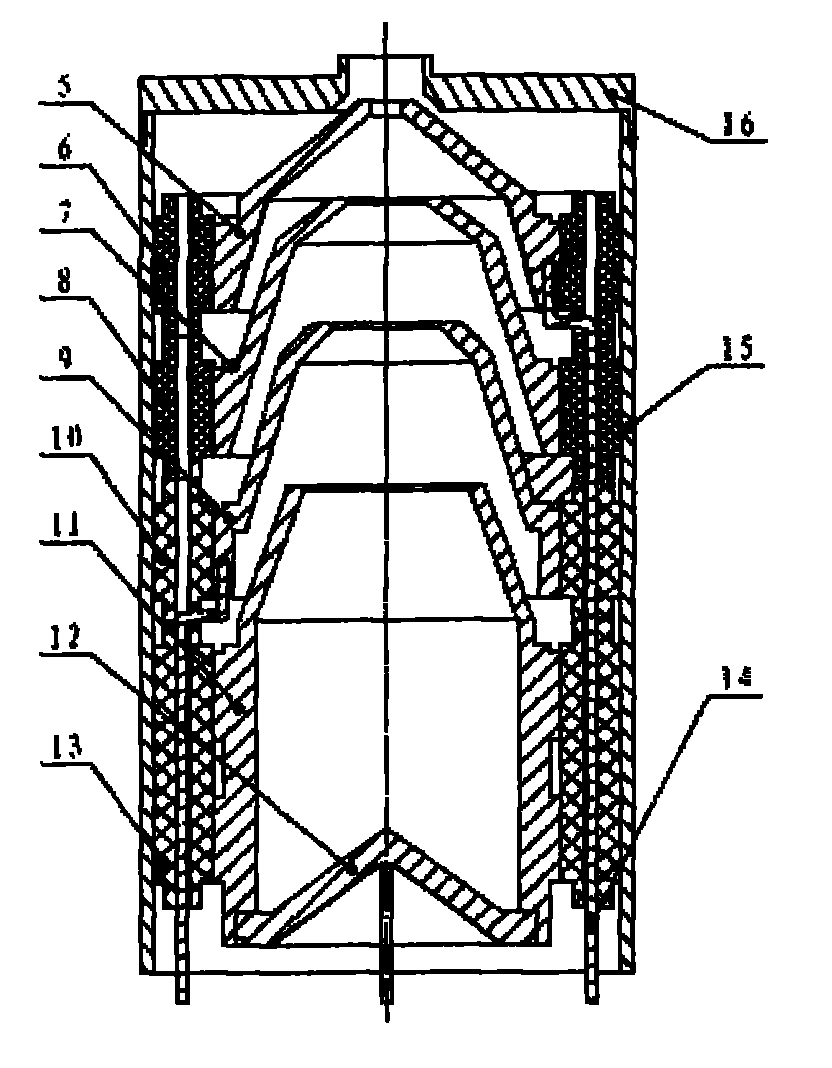

Four-stage depressed collector for space traveling-wave tube

A collector and traveling wave tube technology, applied in the field of collectors, can solve the problems of increasing the number of power supply circuits and increasing the complexity of the power supply, achieving good heat dissipation and improving recovery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution adopted in the present invention is: each collector electrode and the outer cylinder of the collector are welded together by insulating ceramics, which not only ensures the insulation withstand voltage performance between each electrode and the outer cylinder, but also effectively transfers the heat of each electrode It is transmitted to the outer cylinder of the collector through insulating ceramics, which facilitates the heat dissipation of the outer cylinder of the collector and improves the heat dissipation capacity of the multi-stage step-down collector. Each collector assembly is arranged in sequence with gaps inside the collector outer cylinder, and the insulation performance between each collector assembly is guaranteed through a vacuum gap. The lead wires of each collector electrode pass through the insulating porcelain tube, and the insulation performance between the electrodes is guaranteed through the insulating porcelain tube. After t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com