Electric contact member and contact probe

A technology of electrical contacts and components, which is applied to contact parts, parts of connecting devices, parts of electrical measuring instruments, etc., can solve the problems of high price of contact probes, achieve economical durability, excellent durability, and reduce usage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Hereinafter, modes for implementing the present invention (hereinafter referred to as "embodiments") will be described with reference to the drawings. In addition, the drawings are schematic diagrams, and it should be noted that the relationship between the thickness and width of each part, the ratio of the thickness of each part, etc. may be different from reality, and of course there are also mutual dimensions between the drawings. The relationship or ratio of different parts of the situation.

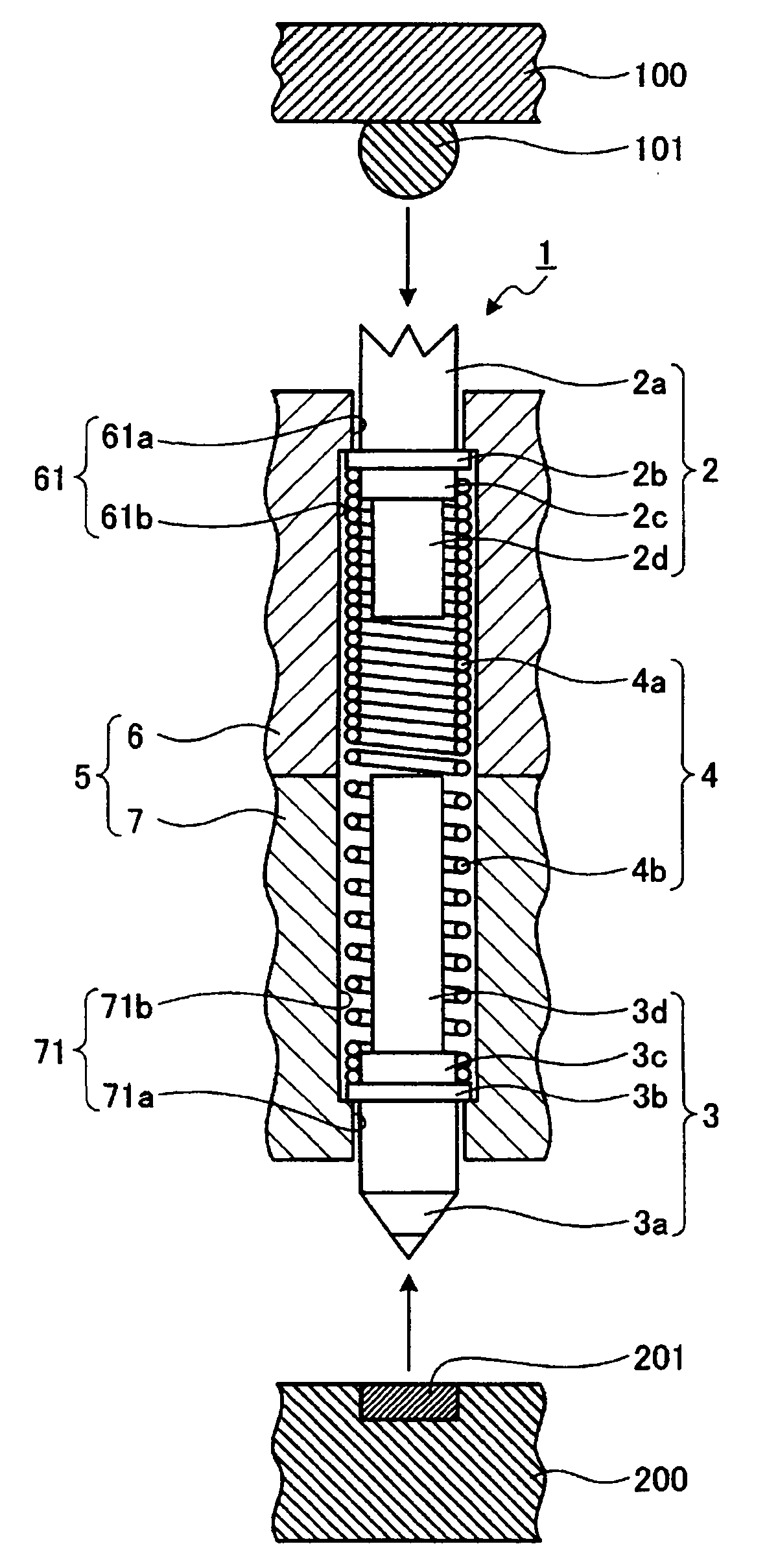

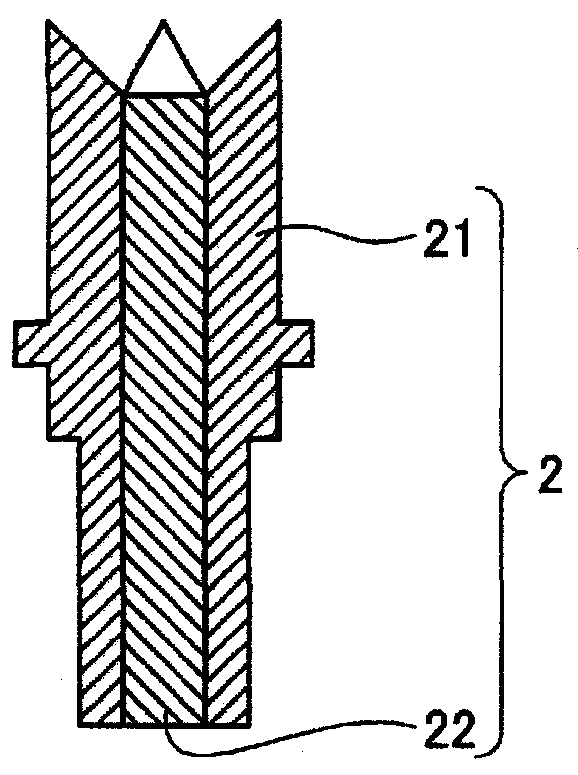

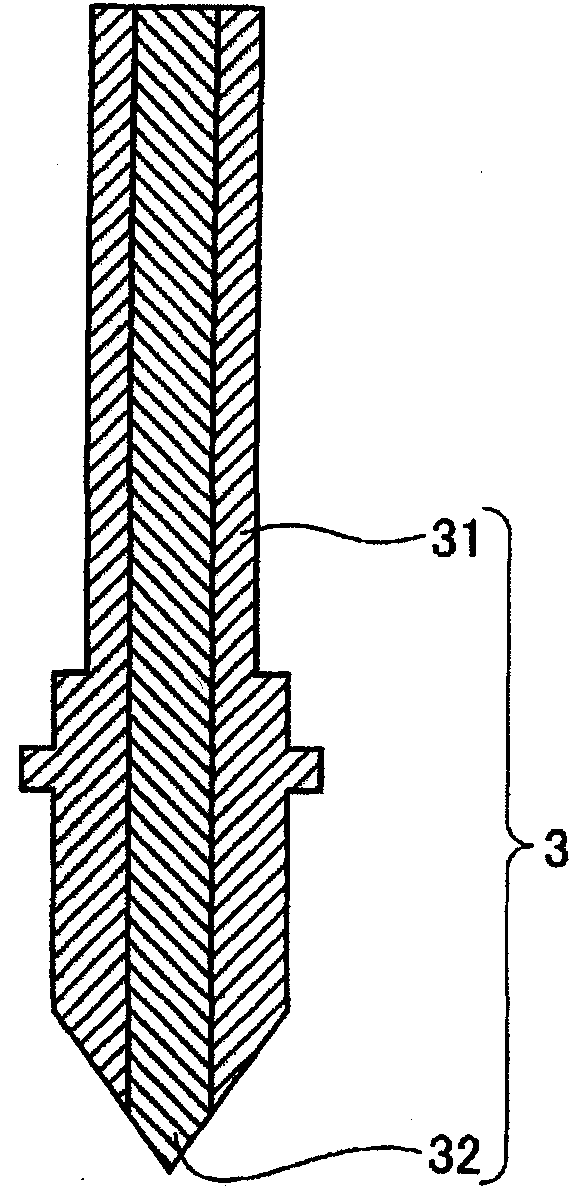

[0019] figure 1 It is a figure which shows the structure of the touch probe which concerns on one Embodiment of this invention. The touch probe 1 shown in this figure includes: a first plunger 2 and a second plunger 3 having front ends protruding in opposite directions; ( figure 1 The up and down direction) the spring member 4 that stretches freely.

[0020] The contact probe 1 is accommodated in the probe holder 5, and electrically connects a semiconductor integrated circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com