Flex-rigid wiring board and electronic device

A technology for flexible circuit boards and electronic equipment, applied in printed circuits, printed circuits, printed circuit manufacturing, etc., can solve problems such as the size limitation of rigid substrates, achieve the effect of shortening signal paths and suppressing signal delays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] Next, a flex-rigid circuit board and an electronic device according to an embodiment of the present invention will be described.

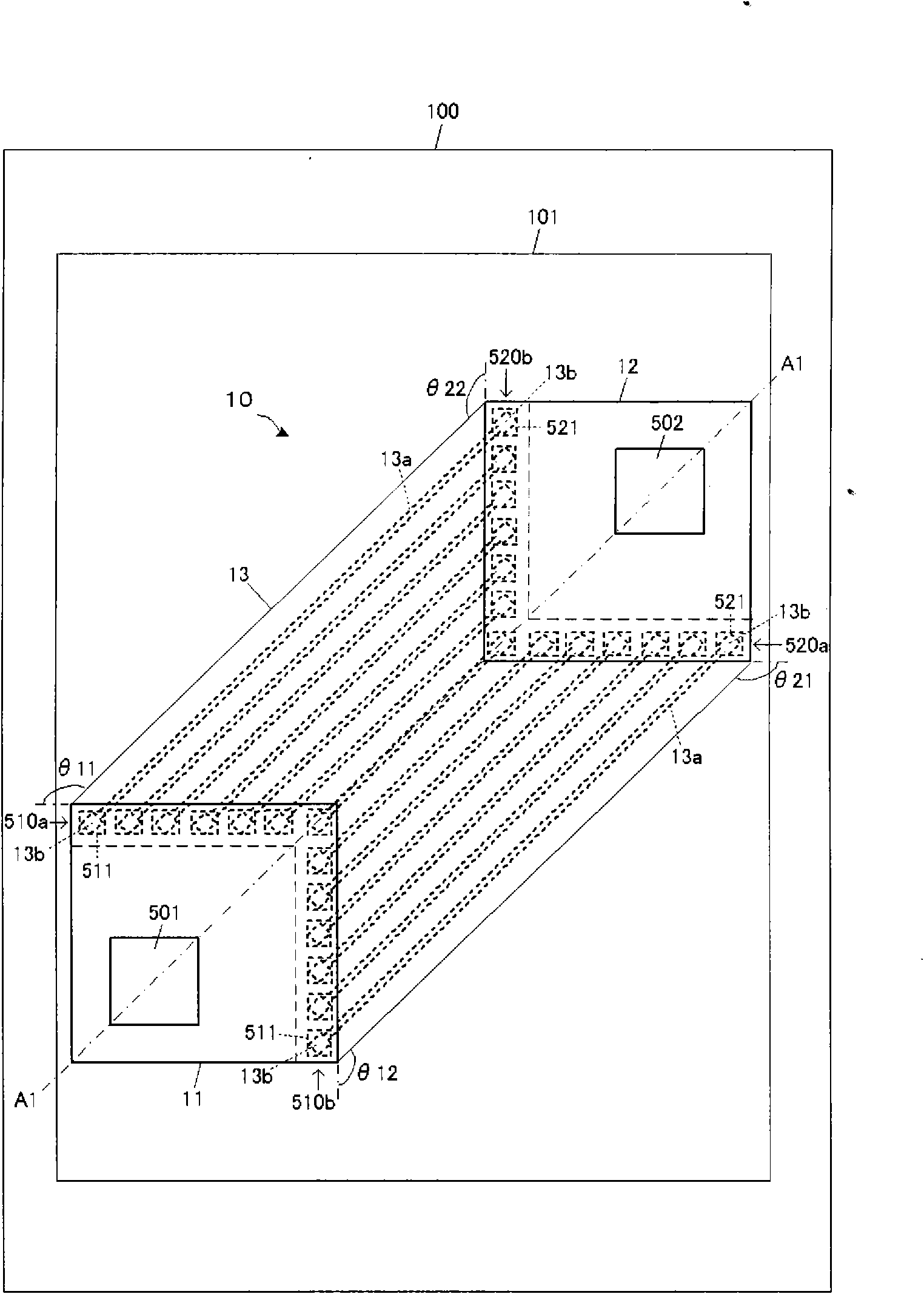

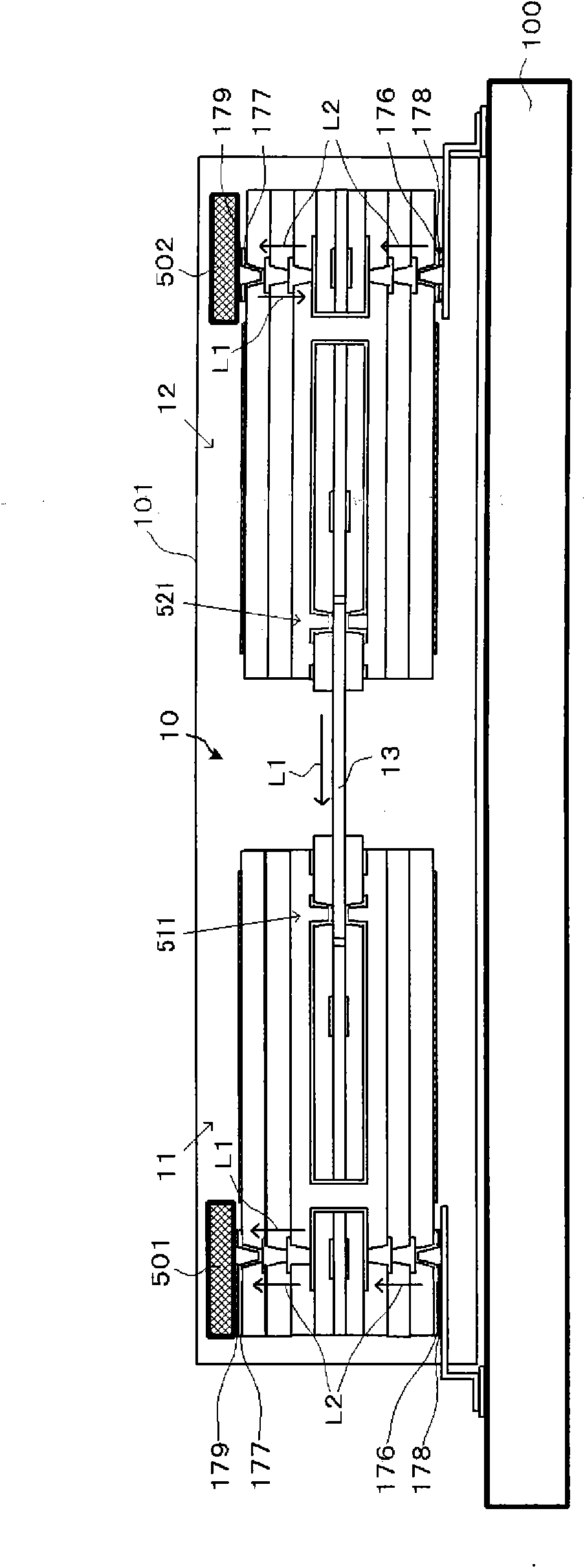

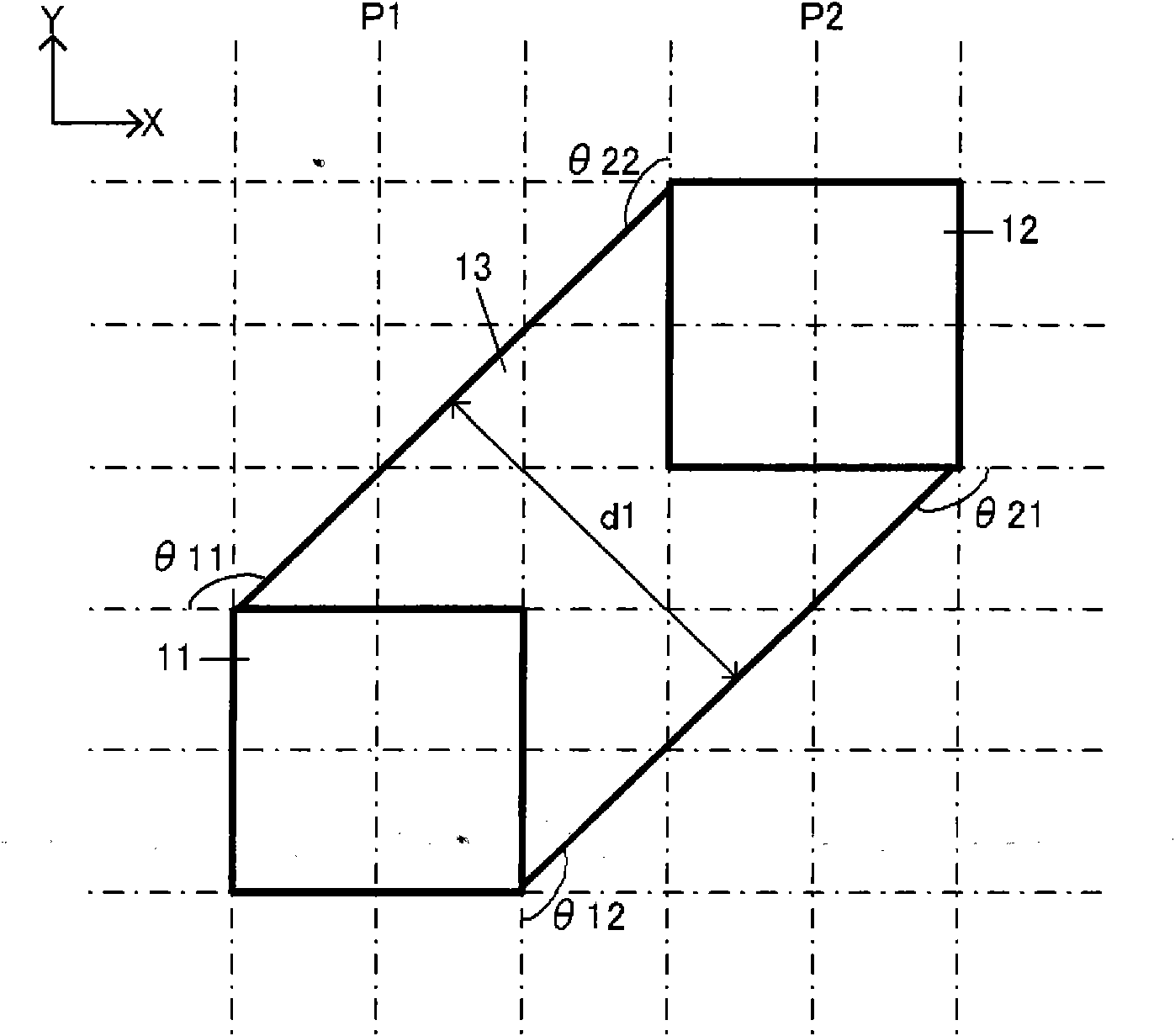

[0076] Such as figure 1 as well as figure 2 ( figure 1 As shown in the plan view structure and cross-sectional structure in A1-A1 cross-sectional view), the electronic device of this embodiment has a rigid-flex circuit board 10 and, for example, a rectangular package 101 . The flex-rigid circuit board 10 is surface-mounted, for example by soldering, on the surface of the rigid motherboard 100 and sealed into the package 101 . The motherboard 100 has a size capable of mounting a plurality of printed circuit boards. Here, as the motherboard 100 , a rigid printed circuit board having a larger wiring pitch (wider pitch width) than the rigid substrates 11 and 12 is used. In addition, the motherboard 100 is a printed circuit board on which connection terminals connectable to the printed circuit board are mounted. Also included in the mothe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com