A kind of wafer-level test probe card and wafer-level test probe card assembly method

A test probe, wafer-level technology, used in measurement devices, electronic circuit testing, measurement of electricity and other directions, can solve the problem of difficult to distribute power supply decoupling, signal noise reduction filter impedance matching, ground potential unequal signal insertion loss probe Card test performance, difficulty in ensuring capacitor placement space, etc., to improve power integrity and signal integrity, improve overall test performance, and reduce dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0063] The following are specific implementations of the wafer-level test probe card of the present invention.

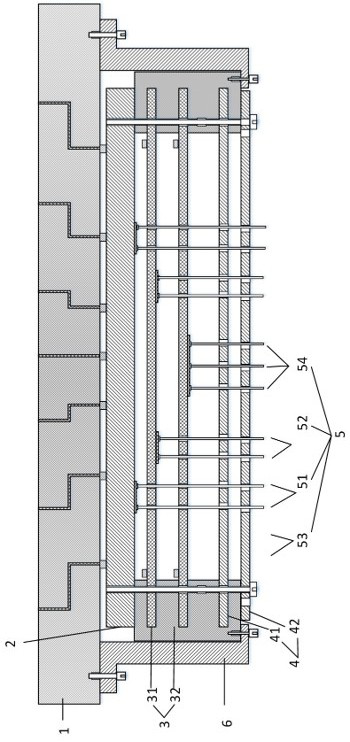

[0064] The wafer-level test probe card under the present embodiment, such as Figure 1-5 As shown, it includes PCB board 1, signal adapter board 2 and probe 5, and also includes intermediary board group 3, guide board group 4 and spacer board group 6;

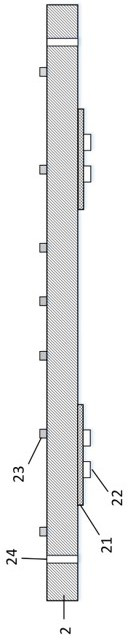

[0065] The surface of the signal transfer board 2 is distributed with a patterned signal transfer board metal interconnection layer 21, a signal transfer board connection structure 22, a signal transfer board signal interface 23 and a signal transfer board pin fixing hole 24; The signal adapter board connection structure 22 is located on the metal interconnection layer 21 of the signal adapter board, and is used to realize the connection between the signal adapter board metal interconnection layer 21 and the probe 5;

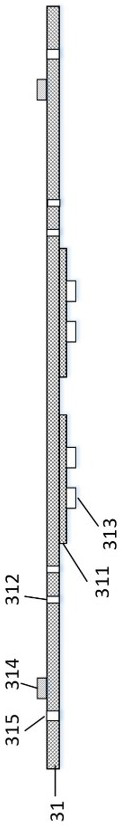

[0066] The interposer group 3 includes a top interposer 31 and a bottom interposer 32, the surface...

specific Embodiment approach 2

[0072] The following are specific implementations of the wafer-level test probe card of the present invention.

[0073] The wafer-level test probe card under this embodiment is further defined on the basis of Embodiment 1: the surface and interior of the signal adapter board 2, the top interposer 31 and the bottom interposer 32 are based on the probes accommodated. 5 types, distributed with power supply decoupling capacitors, signal filtering and noise reduction circuits and / or impedance matching circuits.

specific Embodiment approach 3

[0074] The following are specific implementations of the wafer-level test probe card of the present invention.

[0075] The wafer-level test probe card under this embodiment is further defined on the basis of the first embodiment: the signal interface 23 of the signal adapter board, the signal interface 314 of the top interposer and the signal interface 324 of the bottom interposer are connected to Signal types include power signals, ground signals, low frequency test signals, or high frequency test signals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com