Processing method of roast whole lamb

A processing method and technology of roasted whole lamb, applied in the fields of application, food preparation, food science, etc., can solve the problems of increasing the processing time of roasted whole lamb, reducing the freshness of meat products, and being unfavorable for large-scale production, so as to promote scale The effect of streamlining production, reducing chances of survival and reproduction, and shortening processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

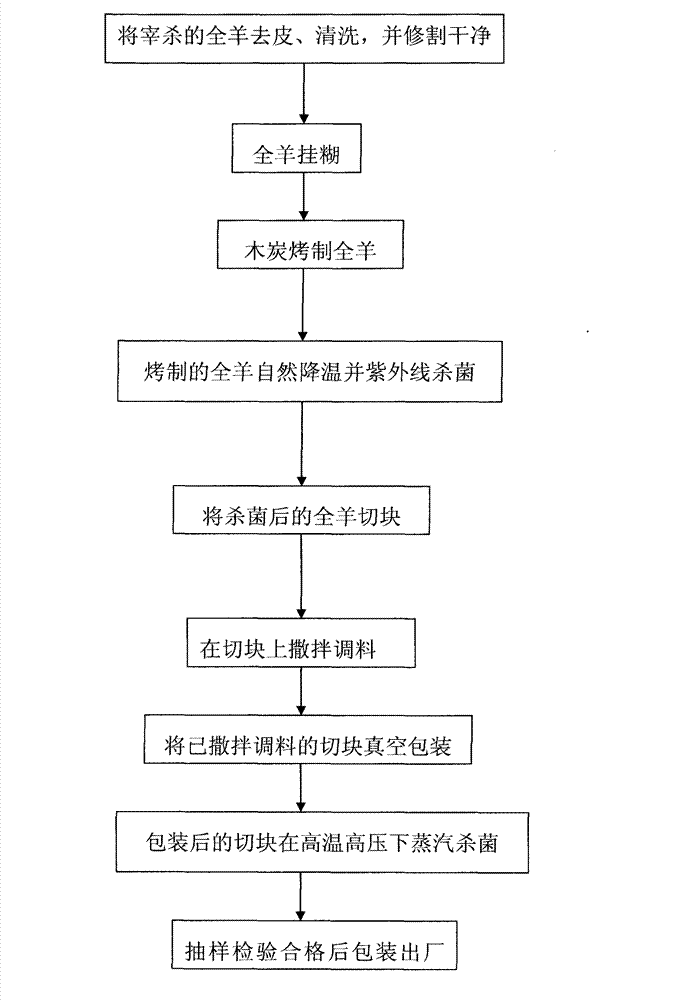

[0020] Such as figure 1 Shown, a kind of processing method of roasting whole sheep, its steps are:

[0021] (1) Choose lambs weighing less than half a year and less than 6-8 kilograms that have passed the quarantine inspection. After slaughtering, the whole lambs are peeled, cleaned, and trimmed clean, and used as whole lamb raw materials.

[0022] (2) Whole sheep paste, 1000 parts by weight Whole sheep takes 100 parts by weight of flour, 200 parts by weight of eggs, 20 parts by weight of cumin, 20 parts by weight of chili powder, 10 parts by weight of pepper, 10 parts by weight of sesame, and 30 parts by weight of table salt Then make a paste with 1000 parts by weight of water, and apply it evenly from the inside to the outside on the cleaned and trimmed sheep carcass by hand, especially the special powder for flour;

[0023] (3) Roast the whole lamb. The whole lamb is roasted with charcoal for 90 minutes, until the outside is charred and the inside is tender, and the meat i...

Embodiment 2

[0032] Step (3) Roast the whole sheep with charcoal for 80 minutes; Step (4) Cool down naturally for 2 hours under ventilated and shaded conditions with a temperature of 4-16°C; Step (8) Steam pressure for sterilization under high temperature and high pressure is 1.8 Atmospheric pressure, the steam temperature is 100°C, and the steam sterilization time is 20 minutes. Other steps are with embodiment 1.

Embodiment 3

[0034] Step (3) Roast the whole sheep with charcoal for 100 minutes; Step (4) Cool down naturally for 4 hours under ventilated and cool conditions with a temperature of 4-16°C; Step (8) The steam pressure for sterilization under high temperature and high pressure is 2.2 Atmospheric pressure, the steam temperature is 150°C, and the steam sterilization time is 60 minutes. Other steps are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com