Novel rotation type compound vibrating screen

A compound vibration and rotary technology, applied in the direction of filter screen, solid separation, grid, etc., can solve the problem that it is difficult to meet higher and higher requirements, and achieve the effect of improving screening efficiency and processing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

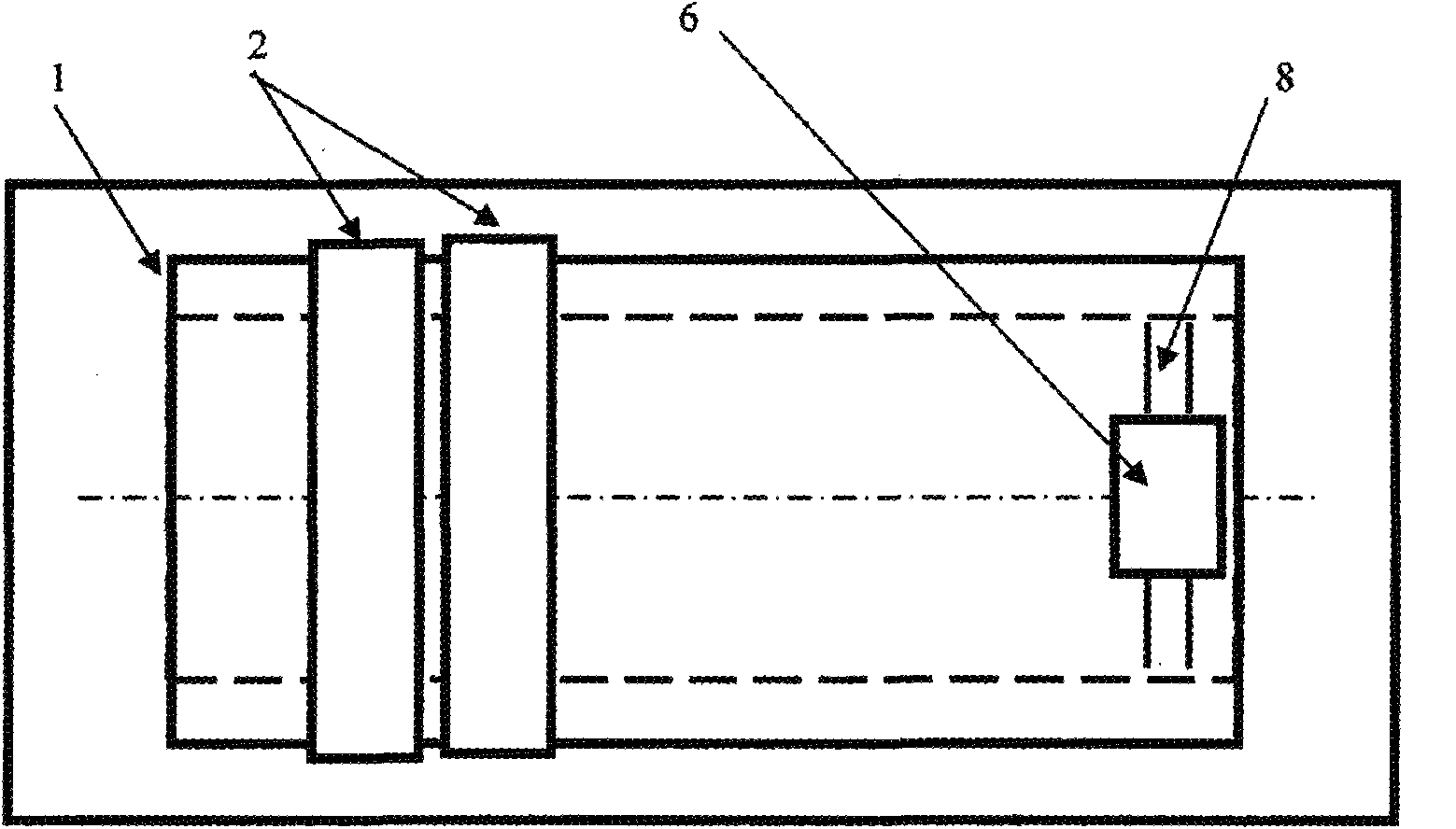

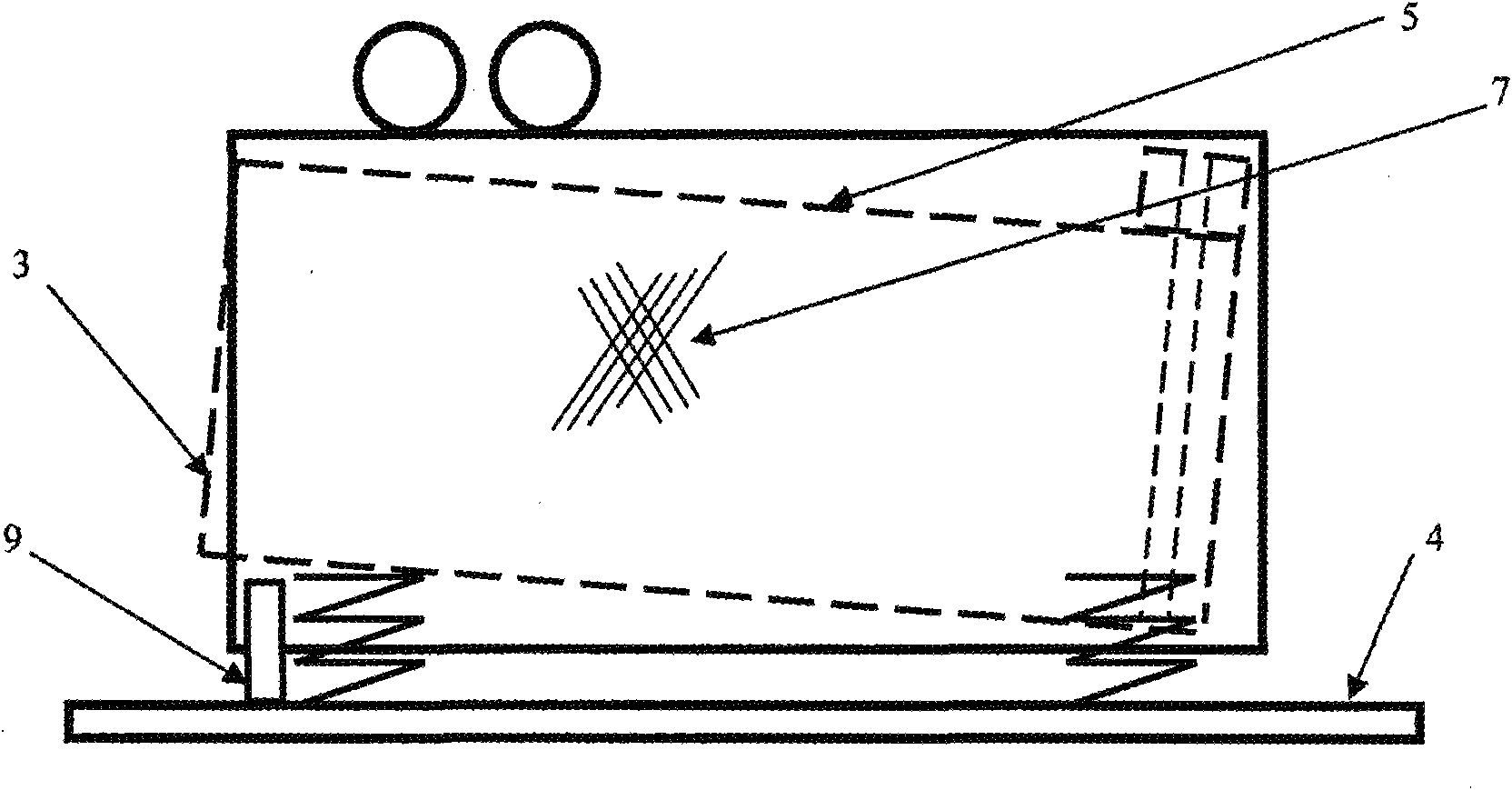

[0027] Example: see figure 1

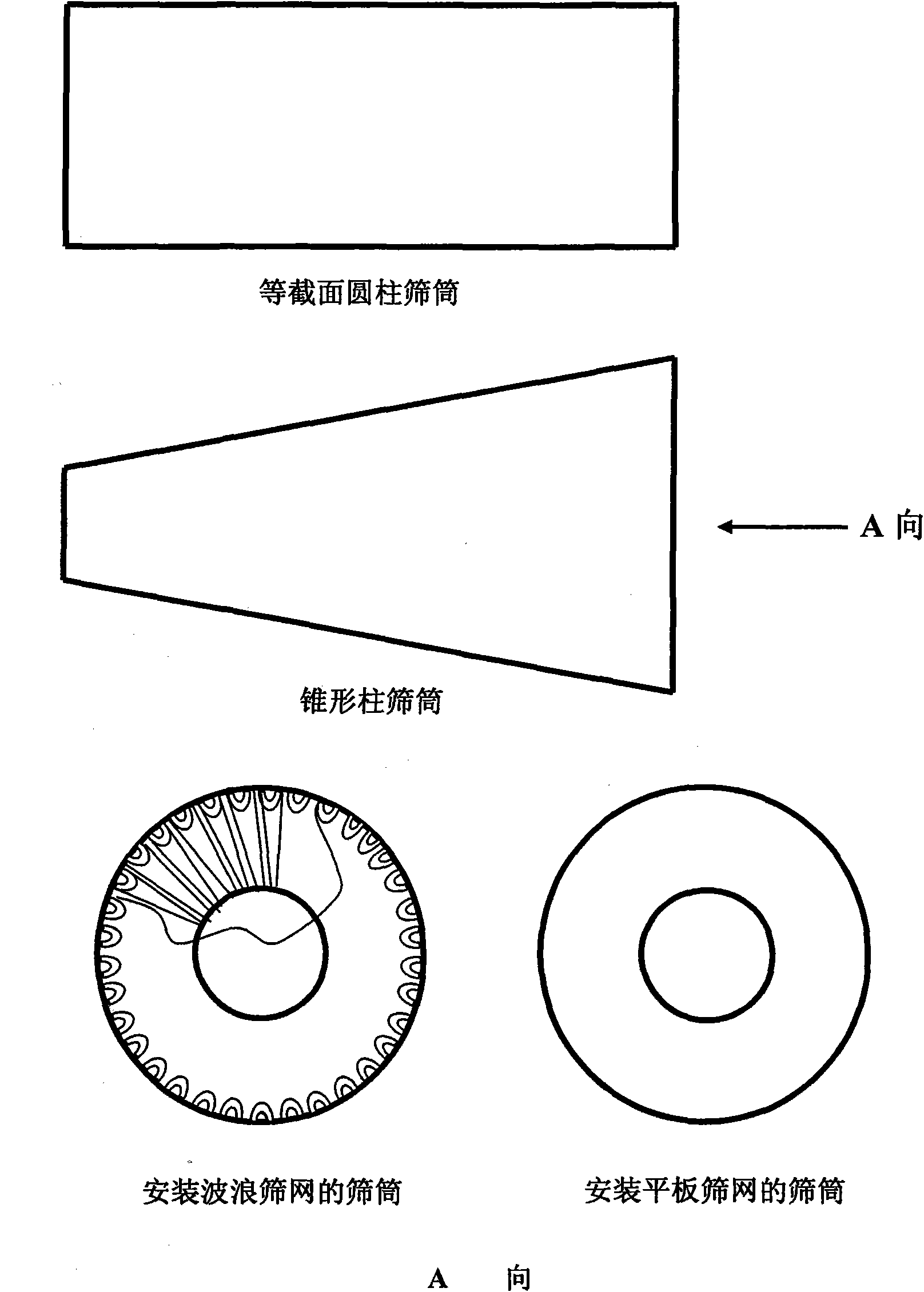

[0028] The patented vibration-rotating composite vibrating screen of the present invention is mainly composed of a screen box 1, an upper-mounted vibration excitation motor 2 installed on the top of the screen box, a supporting damping spring 3, a base 4, a screen cylinder 5, an anti-vibration transmission motor 6, and a multi-layer cylinder. Formula sieve 7 etc. are formed. The screen cylinder 5 is installed on the screen box 1 . The screen box 1 is excited by the vibration excitation motor 2, and the screen cylinder 5 is driven by the anti-vibration transmission motor 6 according to the required law.

[0029] The anti-vibration transmission motor 6 drives the sieve drum 5 to rotate according to a predetermined law through a transmission belt 8 .

[0030] The screen box 1 is self-synchronously excited by the excitation motor 2 to vibrate in various trajectory modes such as circles, straight lines, translational ellipse, straight line, or elli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com