Cleaning and drying integrated car washing line

A technology of car washing line and cleaner, which is applied in the direction of vehicle external cleaning devices, etc., can solve the problems of high energy consumption, high water consumption, and large floor space, and achieve the effect of small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

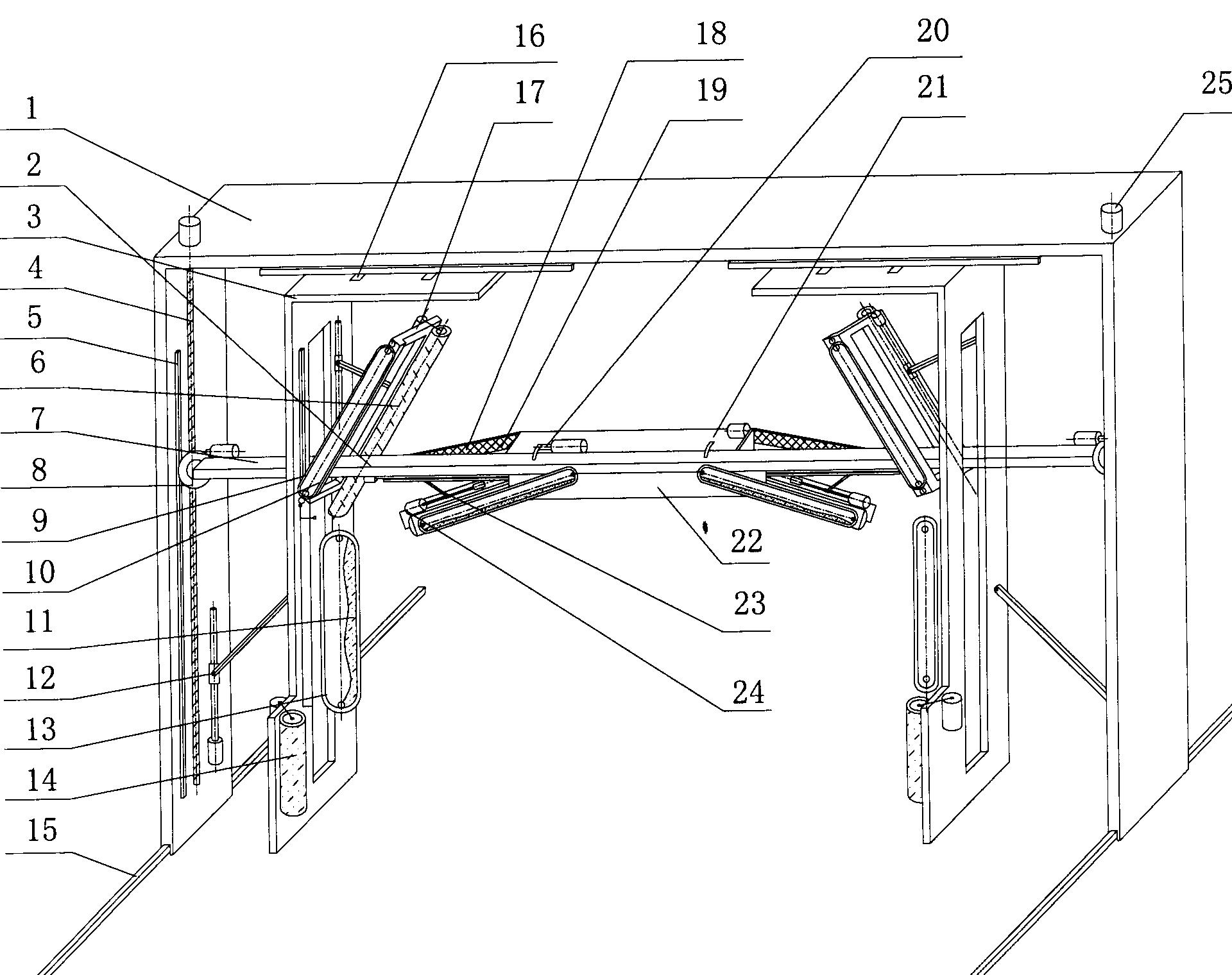

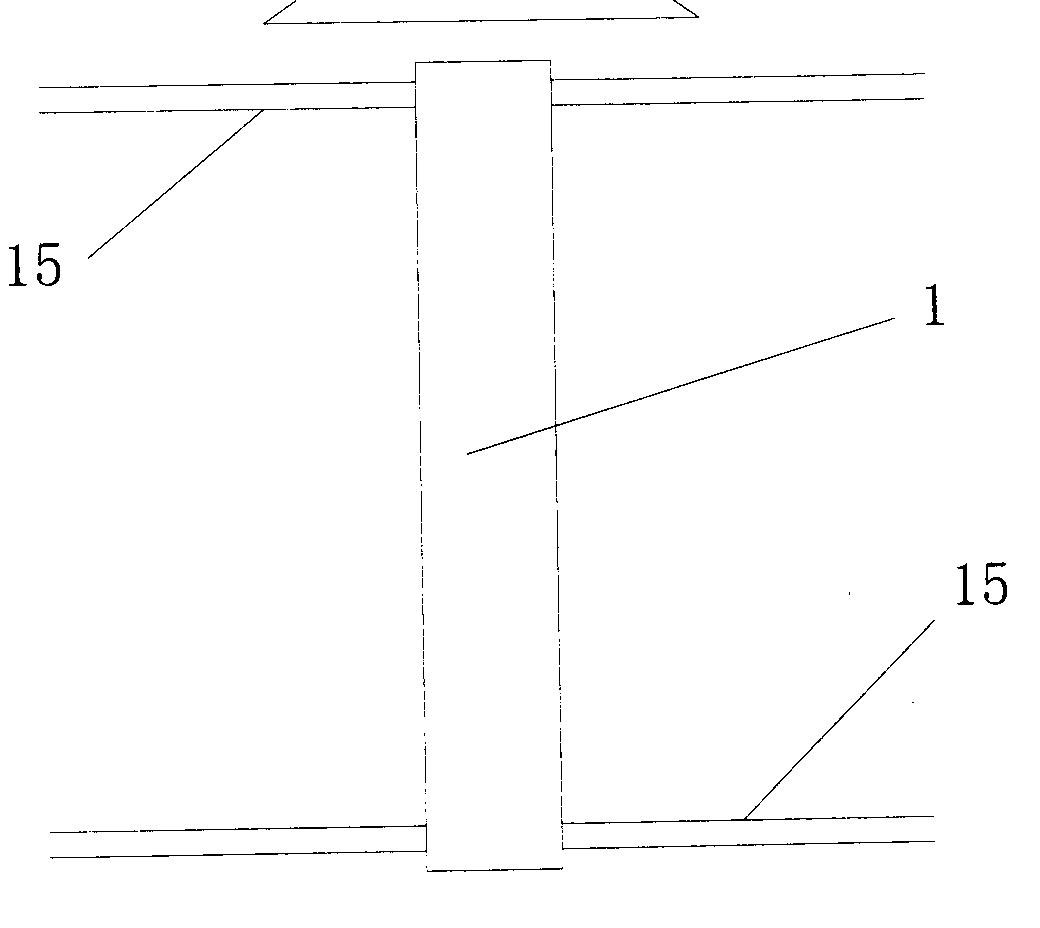

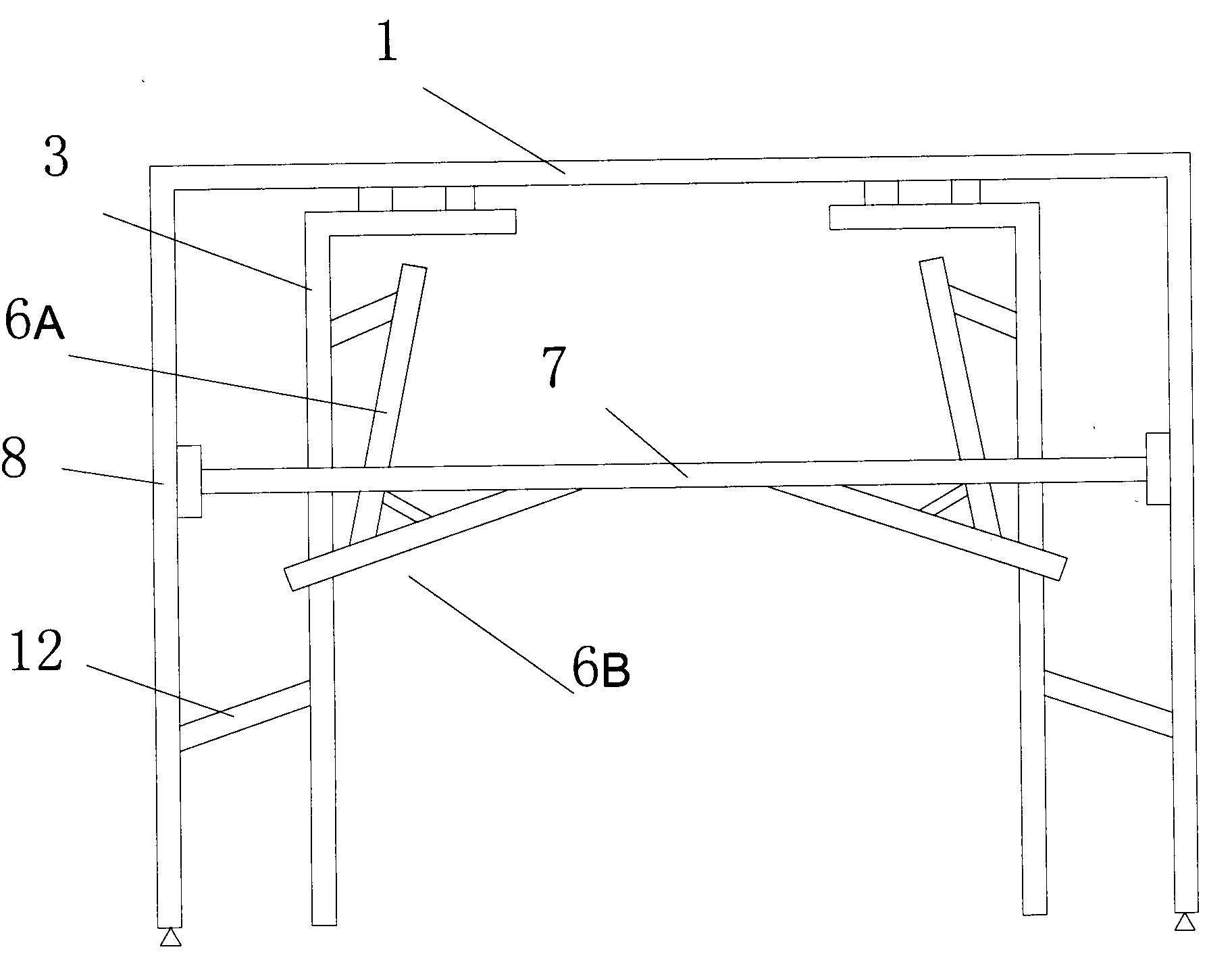

[0021] The cleaning and drying integrated car washing line includes water supply and cleaning liquid pipelines, sensor devices and electrical devices for performing control. There are pulleys at the lower end of the gantry frame 1 that intersect with two parallel slideways on the ground perpendicularly and move in the frame slideway 15. One set Gantry frame structure and slides, see figure 1 , figure 2 , which is characterized in that only one group of gantry frames is provided, slideways are provided on the inner frame and beams, columns and horizontal bars, and lead screws are also provided on all parts except the beams, see Figure 4 There are two column cleaning devices 3 symmetrically arranged in the gantry frame, and the upper ends of the two columns of the column cleaning device 3 are at right angles to each other, see Figure 4 , the lower part of the column is connected with the screw in the gantry frame through the telescopic pull rod 12, and the upper slideway 16 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com