Extensible paper for paper bag and production method thereof

A production method and paper bag technology are applied in the field of extensible paper bag paper and its production, which can solve the problems of high quantitative paper being unfavorable to save resources, high tear strength of extensible paper, etc. The effect of uniformity and consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

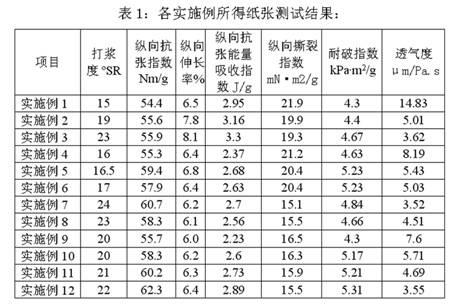

Embodiment 1

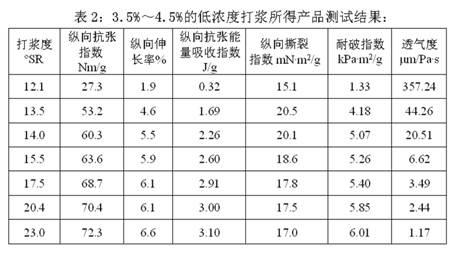

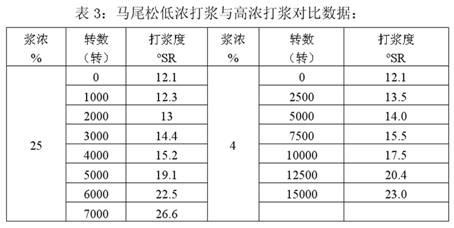

[0019] All use masson pine sulfate natural color pulp, the beating concentration is 23%, the beating degree is 15oSR, after beating, the pulp is desanded, seasoned, pressure sieved, screened, pressed, pre-dried, extensible compression, post-dried, rolled Taking, rewinding, and packaging to produce a weight of 85-87g / m 2 stretchable paper bag.

Embodiment 2

[0021] All use masson pine kraft natural color pulp, the beating concentration is 25%, the beating degree is 19oSR, after beating, the pulp is desanded, seasoned, pressure sieved, screened, pressed, pre-dried, extensible compression, post-dried, rolled Taking, rewinding, and packaging to produce a weight of 85-87g / m 2 stretchable paper bag.

Embodiment 3

[0023] All use masson pine sulfate natural color pulp, the beating concentration is 28%, the beating degree is 23oSR, after beating, the pulp is desanded, seasoned, pressure sieved, screened, pressed, pre-dried, extensible compression, post-dried, rolled Taking, rewinding, and packaging to produce a weight of 85-87g / m 2 stretchable paper bag.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Longitudinal tensile index | aaaaa | aaaaa |

| Burst index | aaaaa | aaaaa |

| Longitudinal tensile index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com