Rotor blade for use with a wind turbine and method for assembling the same

A technology for wind turbines and rotor blades, which is used in wind turbine combinations, wind turbines, and wind turbines in the same direction as the wind. The effect of power generation and total cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

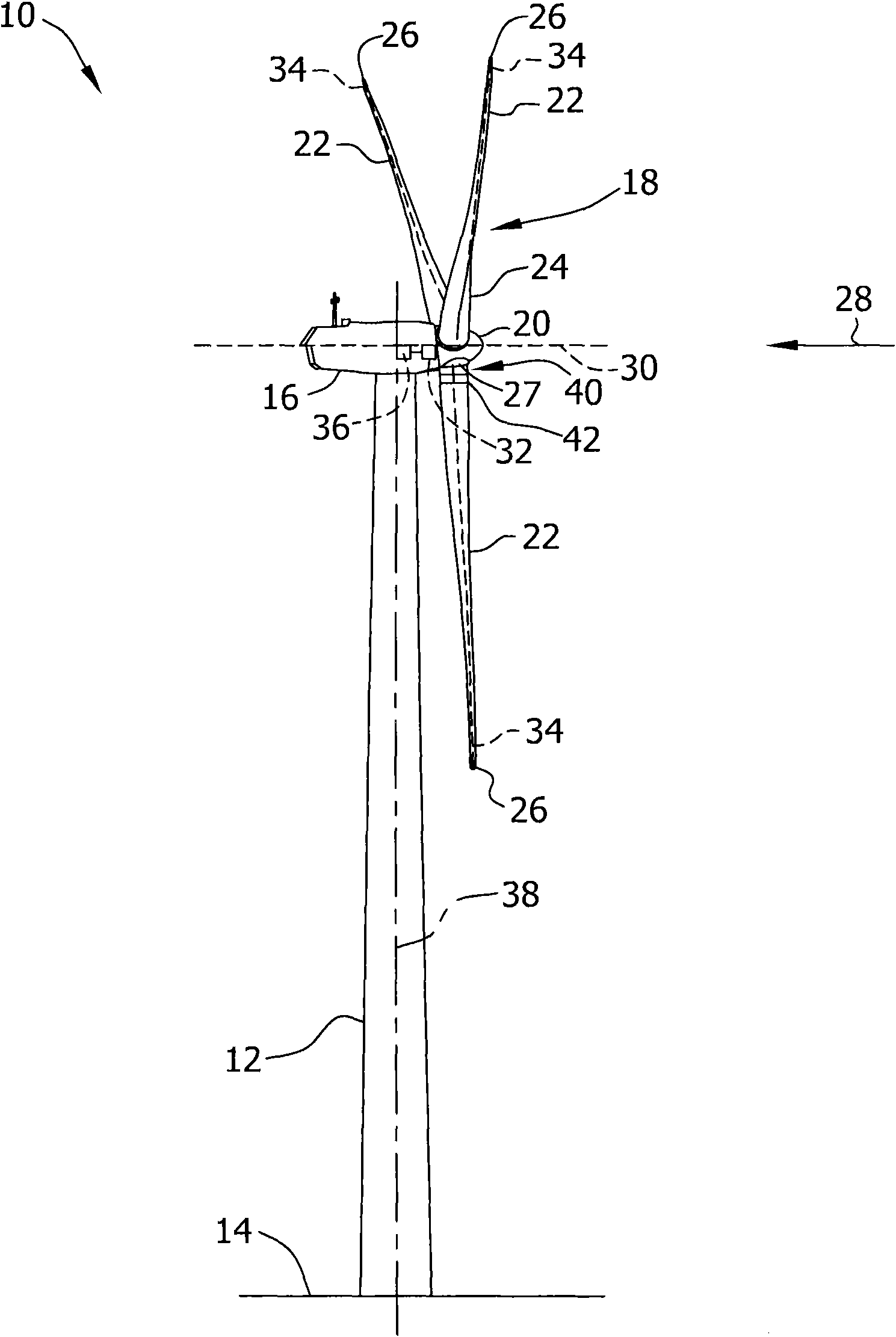

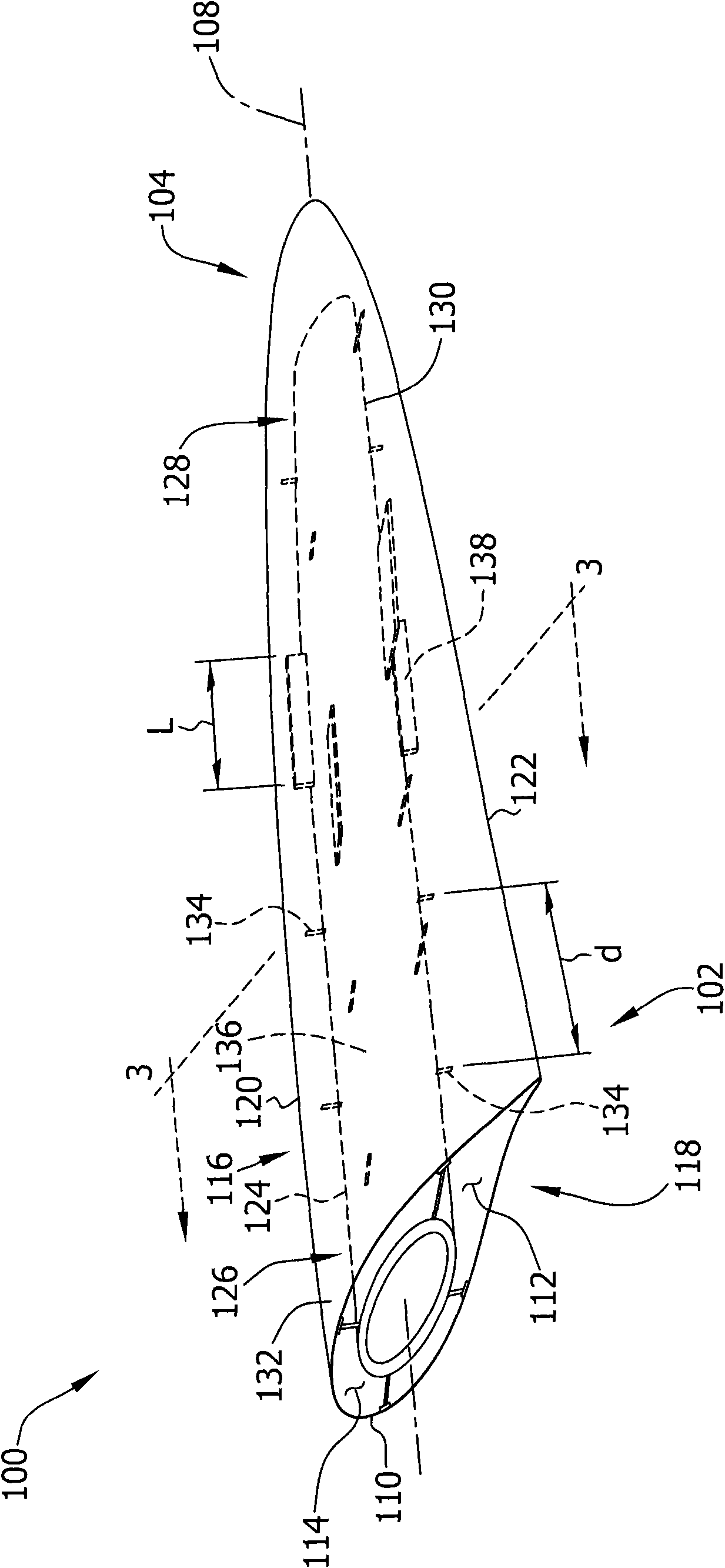

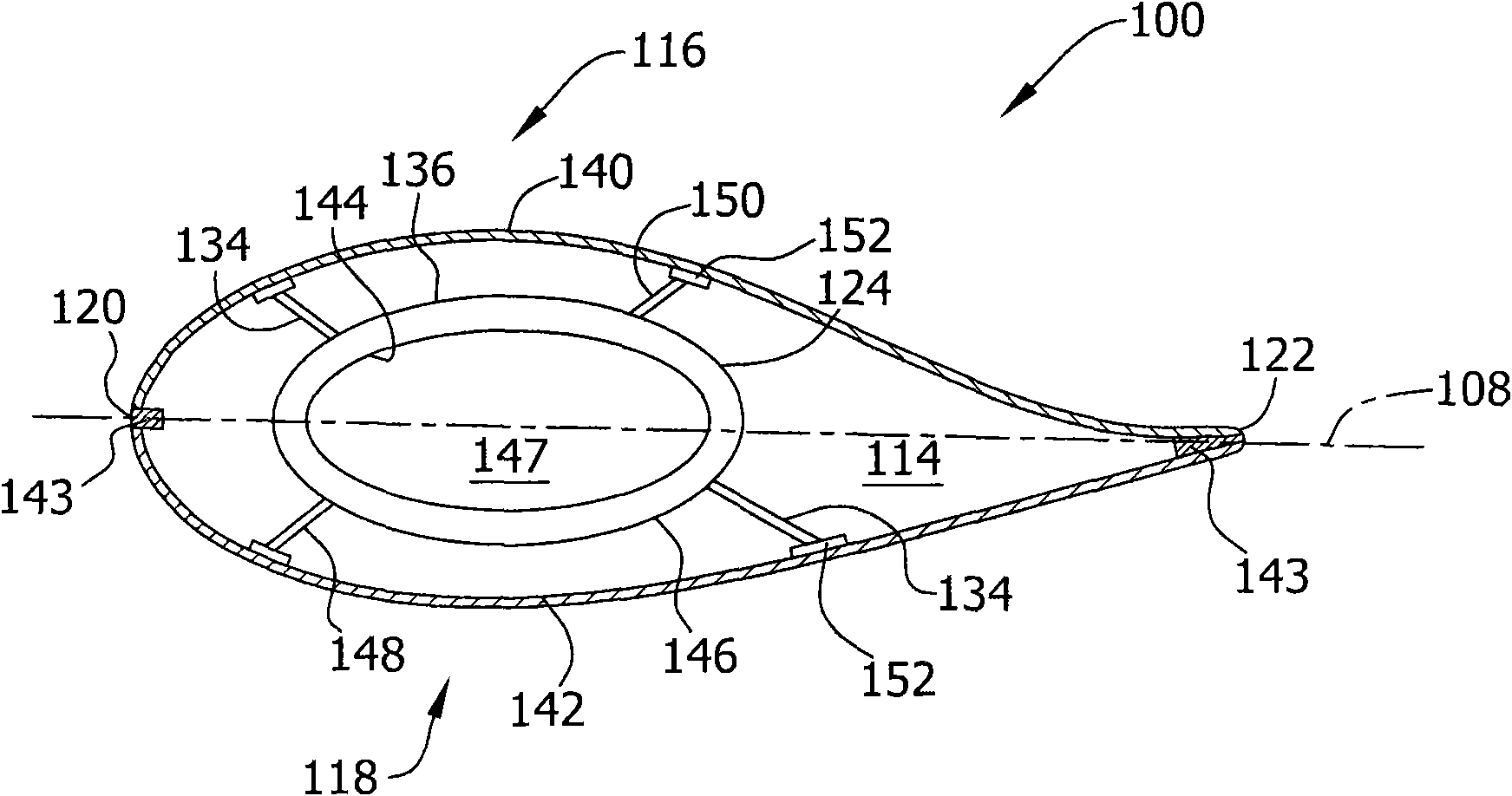

[0110] Embodiments described herein include a wind turbine that includes at least one rotor blade having an airfoil shape along the entire length of the rotor blade to facilitate increasing the annual power generation of the wind turbine. More specifically, the rotor blades described herein include a structural support assembly positioned within the rotor blade cavity, the structural support assembly being coupled to the wind turbine pitch bearing to facilitate having an airfoil shape at or near the hub of the wind turbine The root part of the rotor blade.

[0111] As used herein, the term "vane" is intended to represent any device that provides a reaction force when in motion relative to a surrounding fluid. As used herein, the term "wind turbine" is intended to represent any device that generates electrical power from rotational energy, and more specifically, converts kinetic energy of wind into mechanical energy and vice versa. As used herein, the term "annual production" ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com