Improved plastic metal loose joint pipe

A technology for metal connectors and plastic parts, applied in the direction of pipes/pipe joints/fittings, pipeline connection layout, mechanical equipment, etc., can solve metal insert corrosion, metal insert and plastic body joint surface leakage, scaling, etc. problems, to achieve the effect of avoiding corrosion, increasing strength, and avoiding the possibility of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

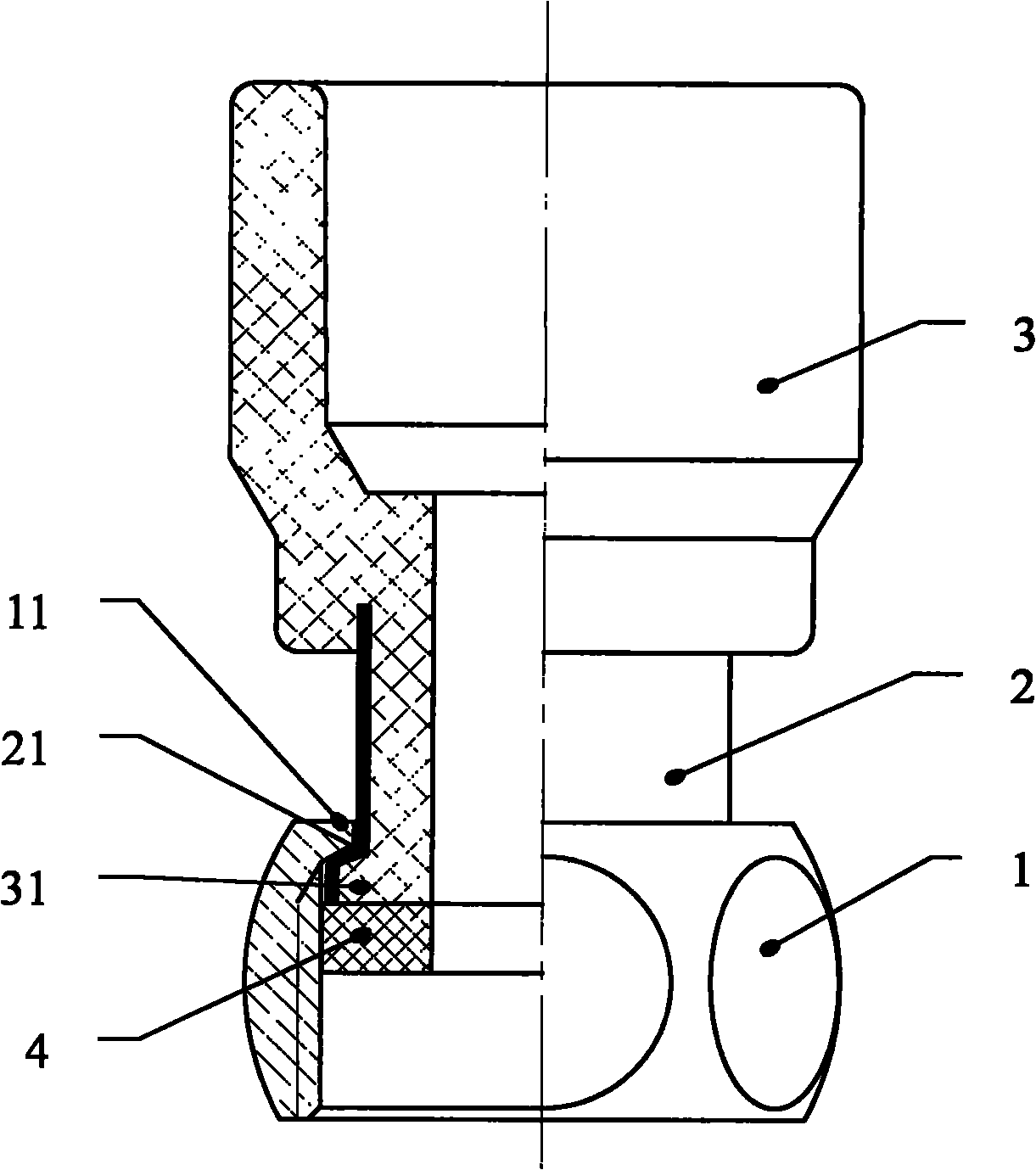

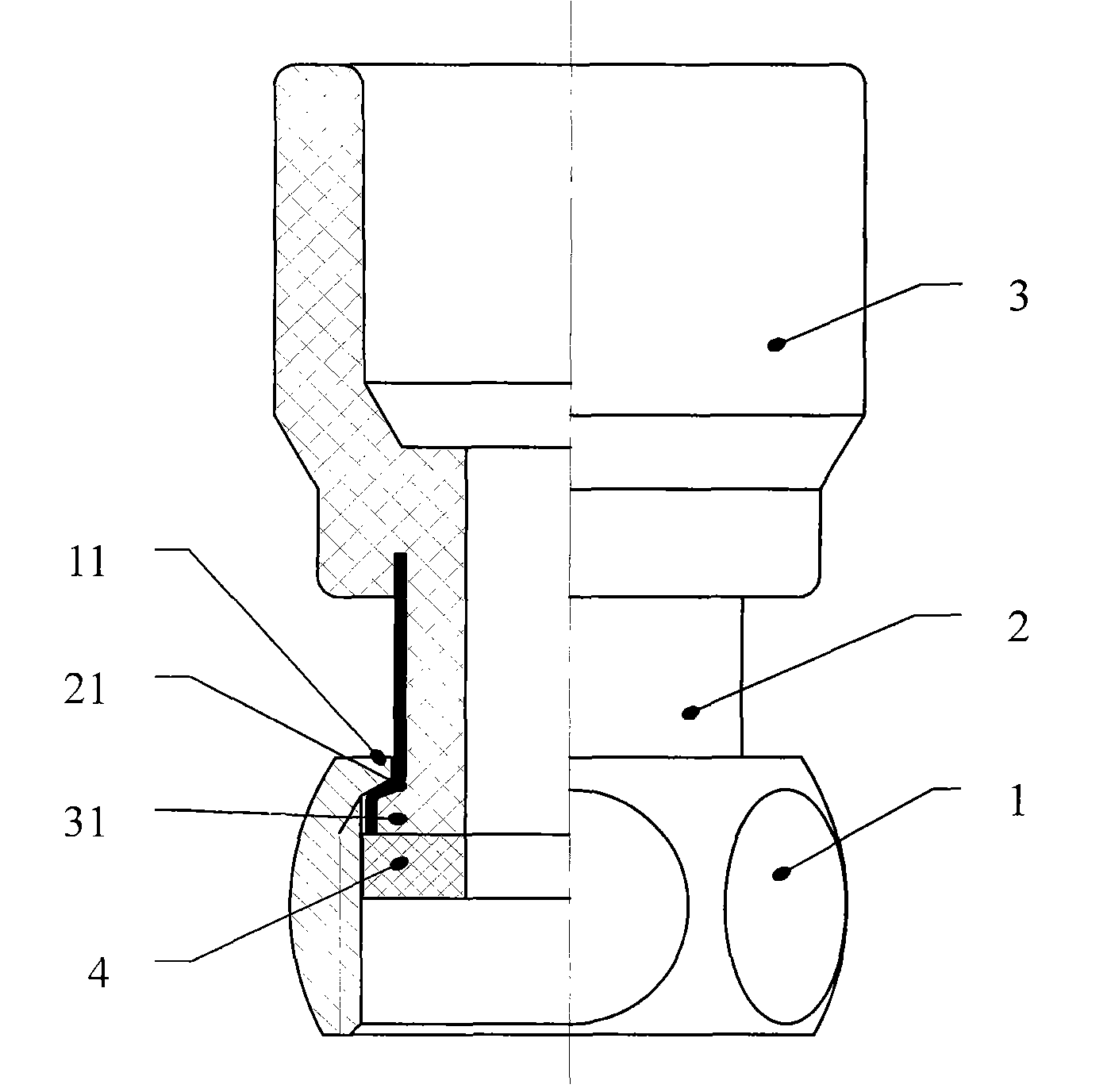

[0011] like figure 1 As shown, an improved plastic-metal union fitting of the present invention is composed of a metal connecting piece 1 and a plastic piece 3 containing a metal insert 2, wherein one end of the plastic piece 3 can be connected to another pipe Or a pipe joint (not shown in the figure) is sealed and connected, the other end of the plastic part 3 is movably connected with the metal connector 1, and the outer edge of the nozzle of the other end of the plastic part 3 is provided with a first flange 31, One end of the metal connector 1 is provided with a second flange 11 protruding toward its inner hole, the outer diameter of the first flange 31 is smaller than the inner diameter of the metal connector 1 and greater than the inner diameter of the second flange 11, the plastic part 3 and A metal insert 2 is provided on the outside of one end of the metal connector 1 , one end of the metal insert 2 is embedded in the plastic part 3 , and the other end of the metal in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com