Automatic feeding green feed chopper

A technology of automatic feeding and green feed, applied in cutting equipment, agricultural machinery and implements, applications, etc., can solve the problems of cutting knife consumption, no actual work effect, low work efficiency, etc., to reduce labor intensity, large production capacity, The effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

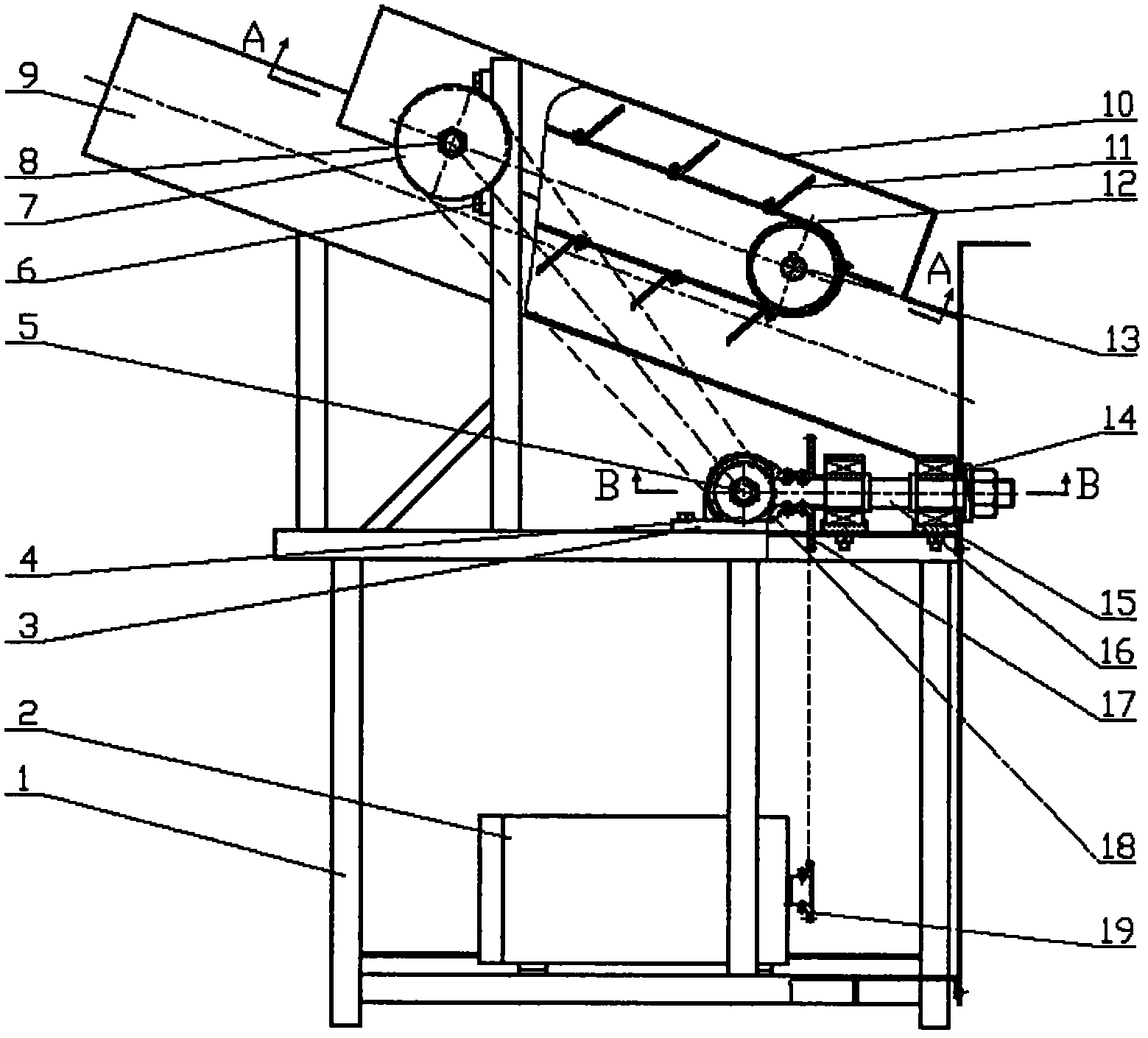

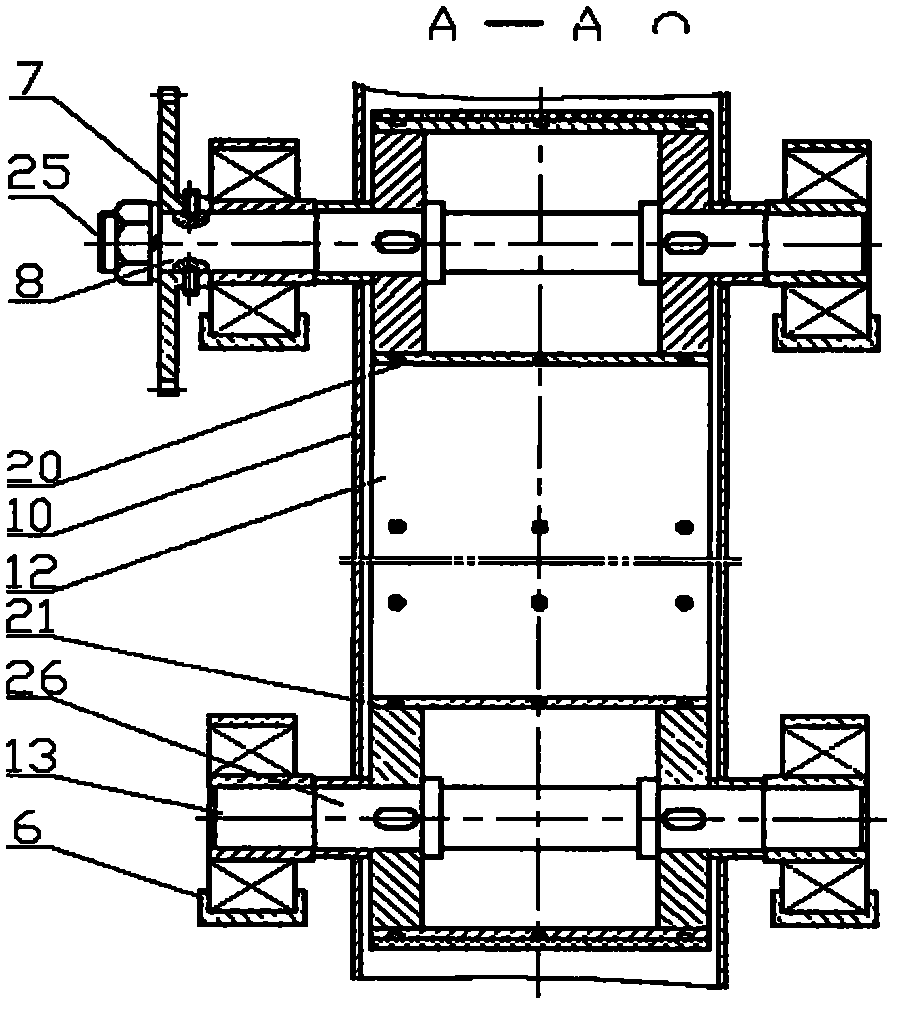

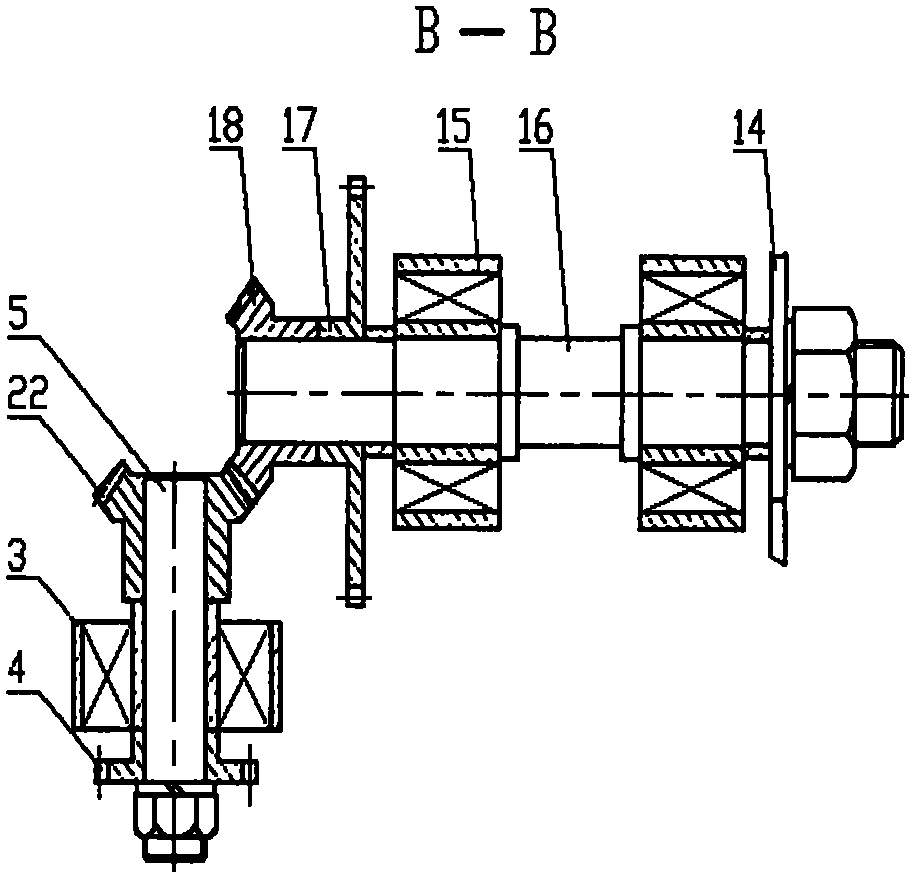

[0015] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0016] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 Shown, a kind of automatic feeding green fodder chopper of the present invention mainly is made of automatic feeding mechanism, transmission transfer mechanism, main cutter 14, frame 1, motor 2. The automatic feeding mechanism is composed of a first roller assembly 25 , a second roller assembly 26 , a conveyor belt 12 and a combination cutter 11 . One end of the first roller shaft 8 is equipped with a large sprocket 7, which rotates under the drive of the small sprocket 4, thereby driving the first roller 20 to rotate, and the rotation of the first roller 20 drives the conveyor belt 12 to move and the second roller 21 to rotate. Conveyor belt 12 is equipped with combination cutter 11, and combination cutter 11 is made up of three wide blades 23, two narrow bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com