Automatic bag binding device

A technology of a tie device and a forming bag is applied in the field of automatic tie device for forming bags, which can solve the problems of low work efficiency, high labor intensity, and inability to guarantee product hygiene quality, etc., so as to improve production efficiency, improve bundling quality and reduce labor costs The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

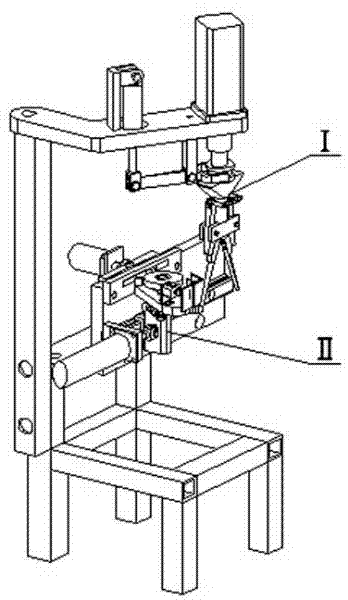

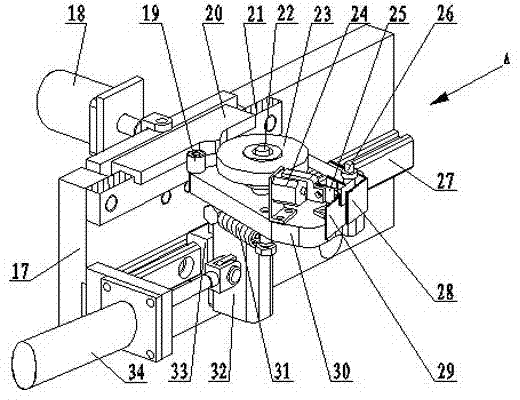

[0027] The forming bag automatic cable tie device described in this embodiment includes two parts: the rotating manipulator mechanism I and the tape automatic packaging mechanism II (such as figure 1 shown).

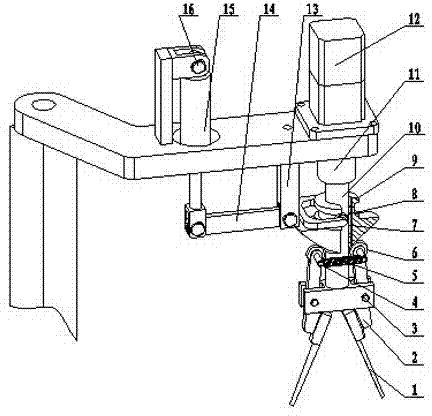

[0028] The first part is the rotating manipulator mechanism (such as figure 2 shown), it consists of a manipulator rotation mechanism and a mechanical finger opening and closing mechanism. The manipulator rotating mechanism is made up of finger 1, swing bar 2, hinge shaft 3, rotating shaft 10, coupling 11, servo motor 12. Wherein two fingers 1 are respectively fixedly connected to the bottom ends of two swing rods 2, and the rotating shaft 10 is a cylinder a at the upper end (such as Figure 5 shown), the lower end has a rectangular parallelepiped support plate b perpendicular to the cylinder (such as Figure 5 shown), the support plate is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com