Heat-radiating, recovering and cooling system for mine

A heat recovery and mine technology, applied in mine/tunnel ventilation, mining equipment, earthwork drilling and mining, etc., can solve problems such as difficulty in cooling and waste of heat, and achieve a good cooling effect in the well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

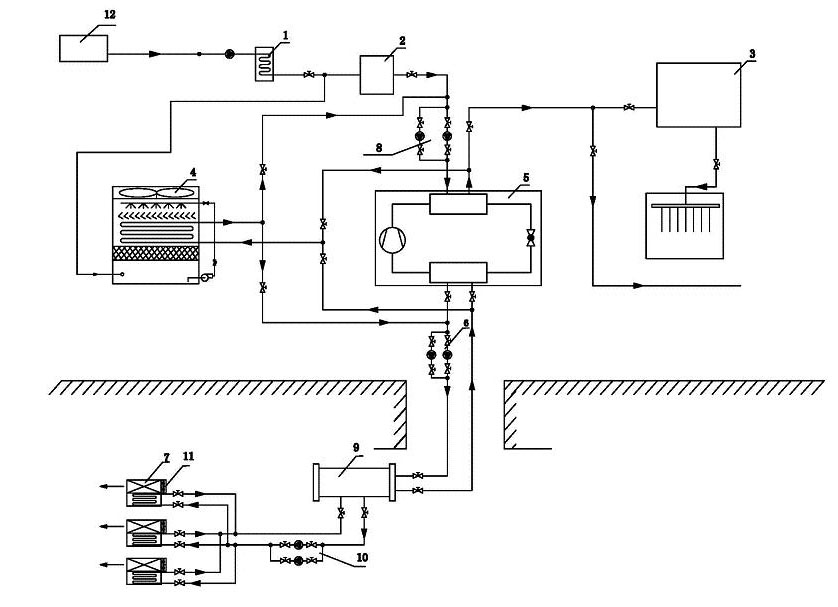

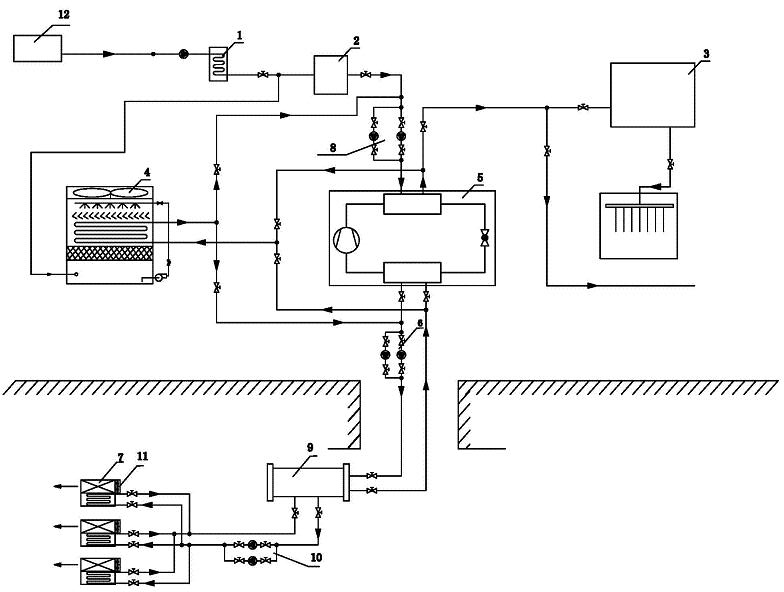

[0013] The principle of the mine heat dissipation recovery and cooling system of the present invention is as follows: figure 1 As shown, the system is divided into two parts: the uphole part and the downhole part, wherein the uphole part includes a closed cooling tower 4, a heat energy recovery device 5, a water treatment device 1, a heat energy recovery device circulating water pump 8, a pressure exchanger circulating water pump 6, Clean water tank 2, hot water tank 3, pipelines and automatic control valves, etc. The underground part consists of pressure exchanger 9, refrigeration cooling device 7, fan 11, well cooling unit circulating water pump 10, pipelines and automatic control valves, etc. The water source 12 is connected to the water inlet end of the water treatment device 1 through pipelines, and the water outlet end of the water treatment device 1 is connected to the closed cooling tower 4 and the clean water tank 2 through valves and pipelines, and the water outlet en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com