Fuel cell engine air turbine compressor with energy recovery

A technology of fuel cells and air turbines, applied in combustion engines, fuel cell additives, internal combustion piston engines, etc., can solve the problems of working pressure establishment, large power loss, slow change of intake pressure, etc., and achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to understand the technical means, technical features, objectives and effects achieved by the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

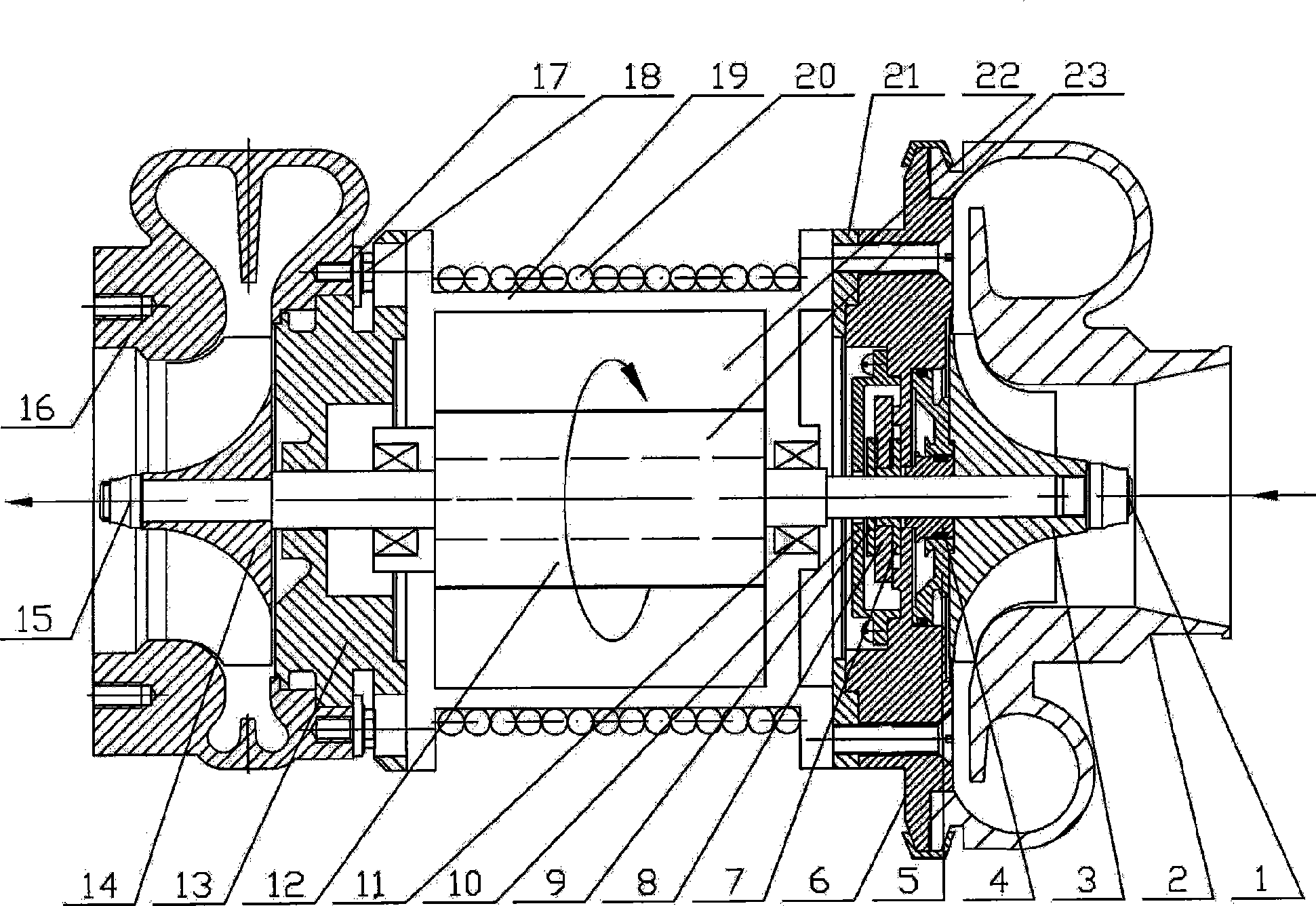

[0014] see figure 1 , a fuel cell engine air turbine compressor with energy recovery, including an electrically driven compressor and a turbine composed of a motor and a compressor, the motor is composed of a casing 19, a stator 22, a rotor 23 and a rotating shaft 12, and the stator is installed on the machine Inside the casing 19, the rotor 23 is installed on the rotating shaft 12, and the rotating shaft 12 is supported in the casing 19 through the high-speed bearings 11 at both ends, and protrudes from its left and right sides.

[0015] A cooling water pipe 20 is surrounded on the outer wall of the casing 19, and the cooling water pipe 20 is connected to a cooling water source so as to cool the motor and ensure the stable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com