Concentric double-stator structured direct-drive cage type induction generator system

A technology of wind power generators and generators, applied in wind power generation, electromechanical devices, electrical components, etc., can solve the problems of large motor space, large rotor size, and no use, etc., to achieve increased power generation, maintenance-free, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

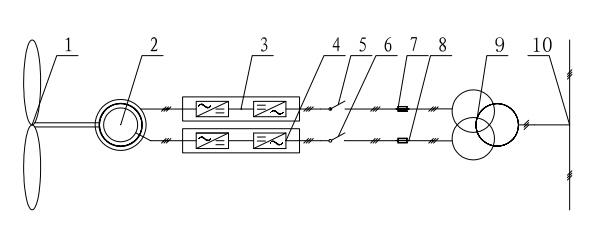

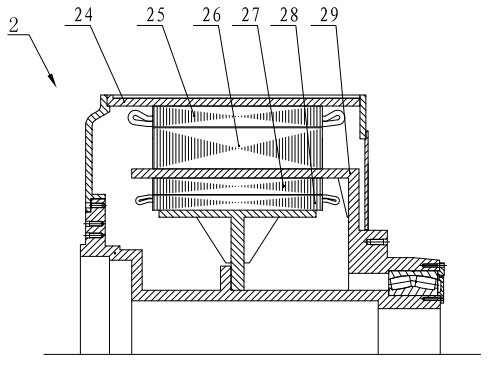

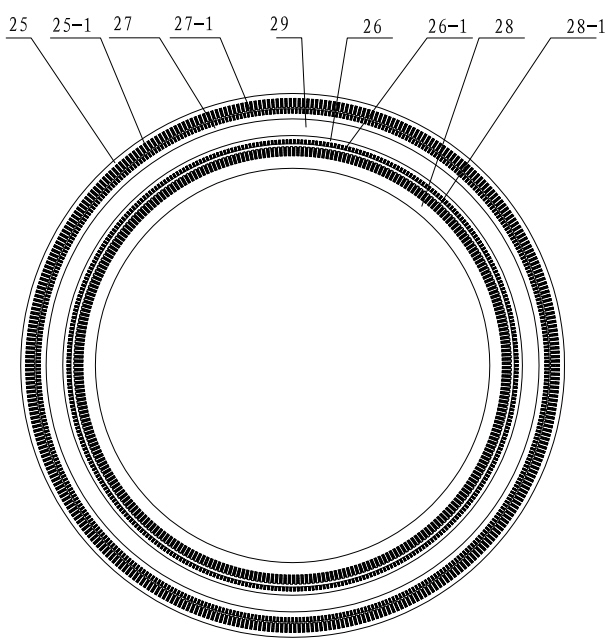

[0013] With the development of power electronics technology and control theory, power electronic converters are used to replace traditional capacitors to provide excitation, which breaks through the bottleneck of capacitor excitation adjustment difficulties, making cage-type asynchronous wind turbines more widely used in wind power systems . Such as figure 2 , image 3 As shown, the concentric dual-stator structure direct drive generator 2 can be regarded as two concentric motors: one is an inner rotor generator, which is composed of an outer stator 25 and an inner rotor 26; the other is an outer rotor generator, Composed of outer rotor 27 and inner stator 28; winding 25-1 is wound on outer stator 25, winding 28-1 is wound on inner stator 28; squirrel cage guide bar 27-1 is inserted into the core of outer rotor 27, and squirrel cage gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com