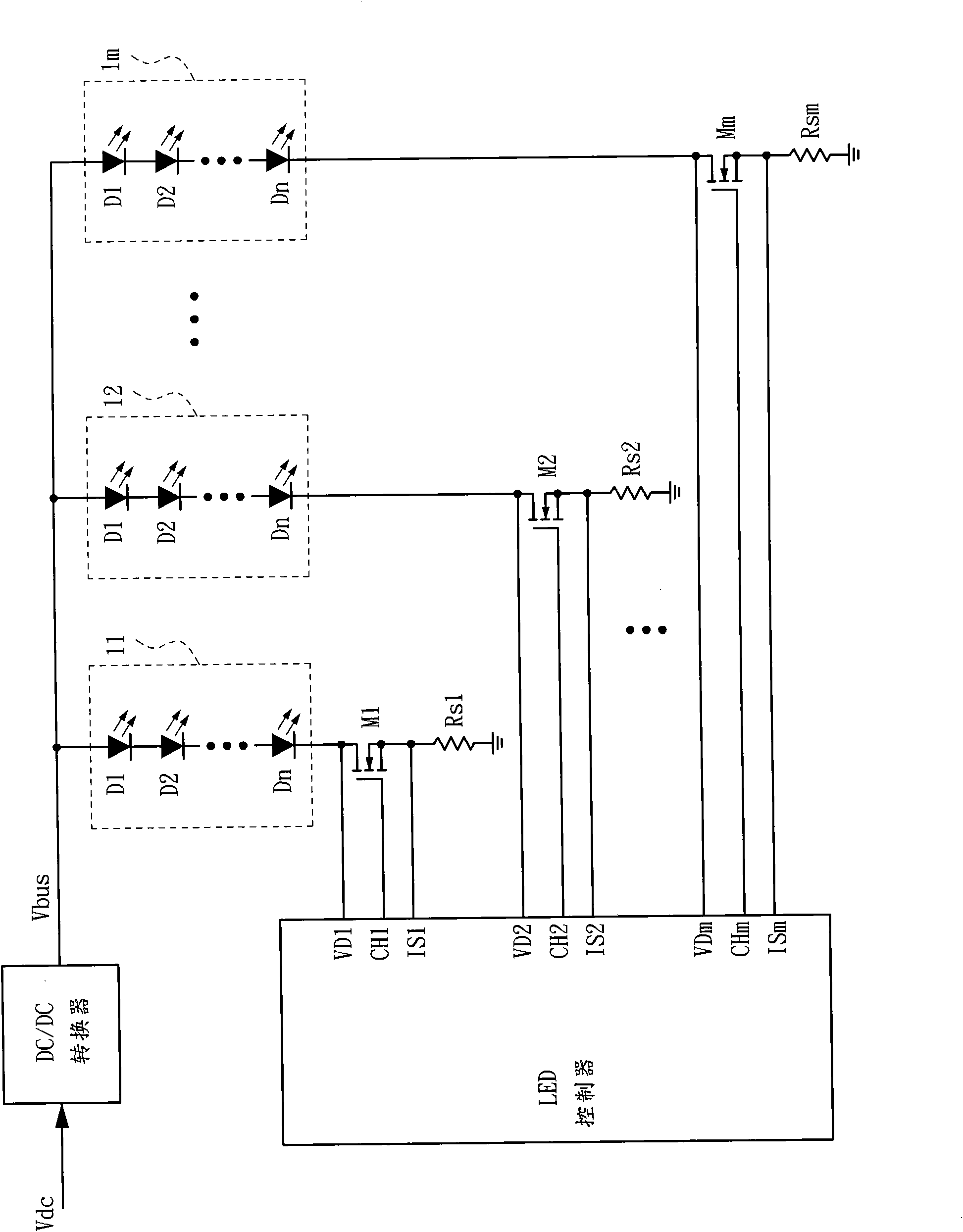

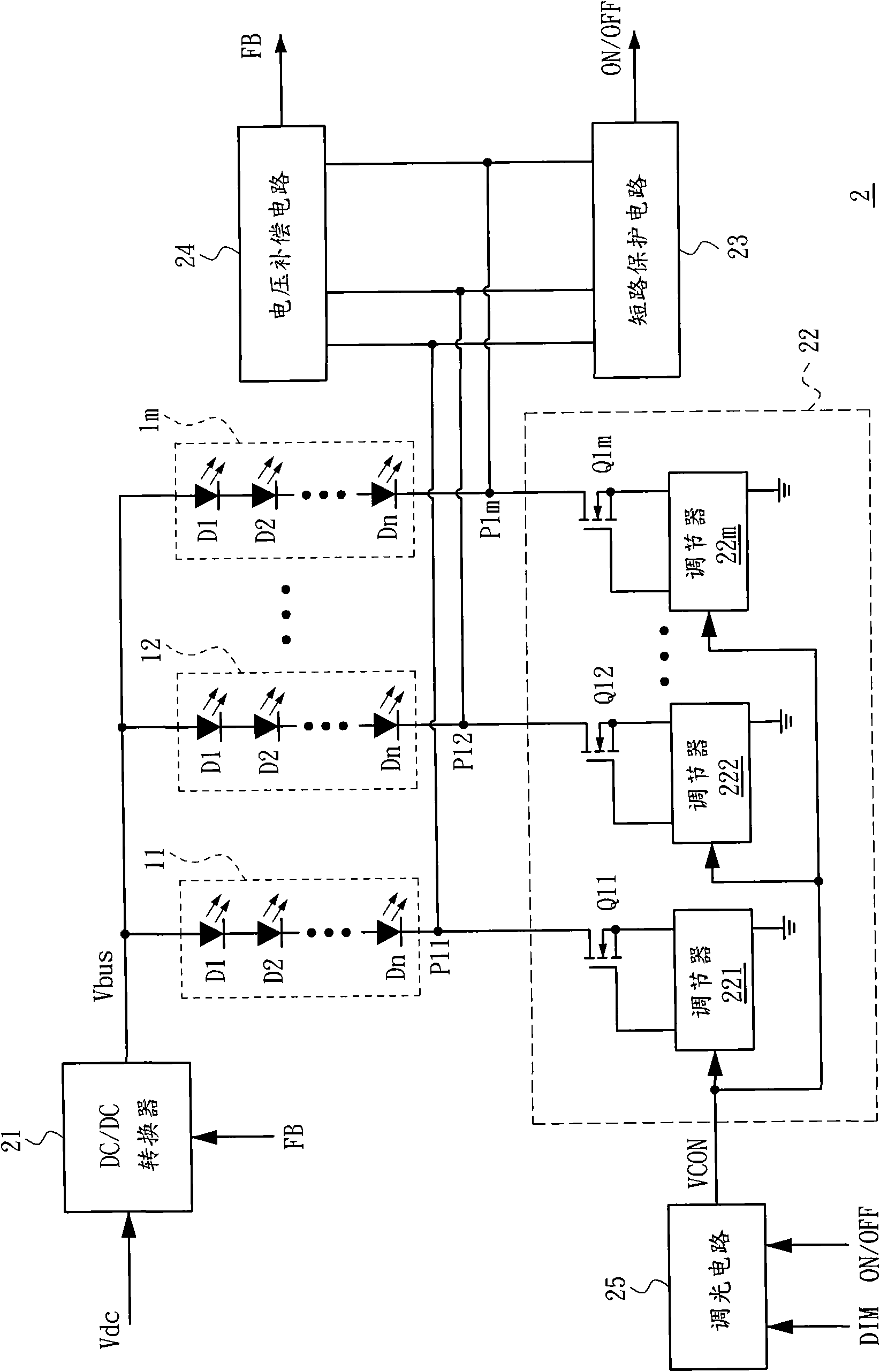

Light-emitting diode driving circuit

A technology of light emitting diodes and driving circuits, which is applied in the layout of electric lamp circuits, light sources, electric light sources, etc., can solve the problems of complicated circuits, rising design costs, and difficult control, and achieves the effect of simple driving circuit structure and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

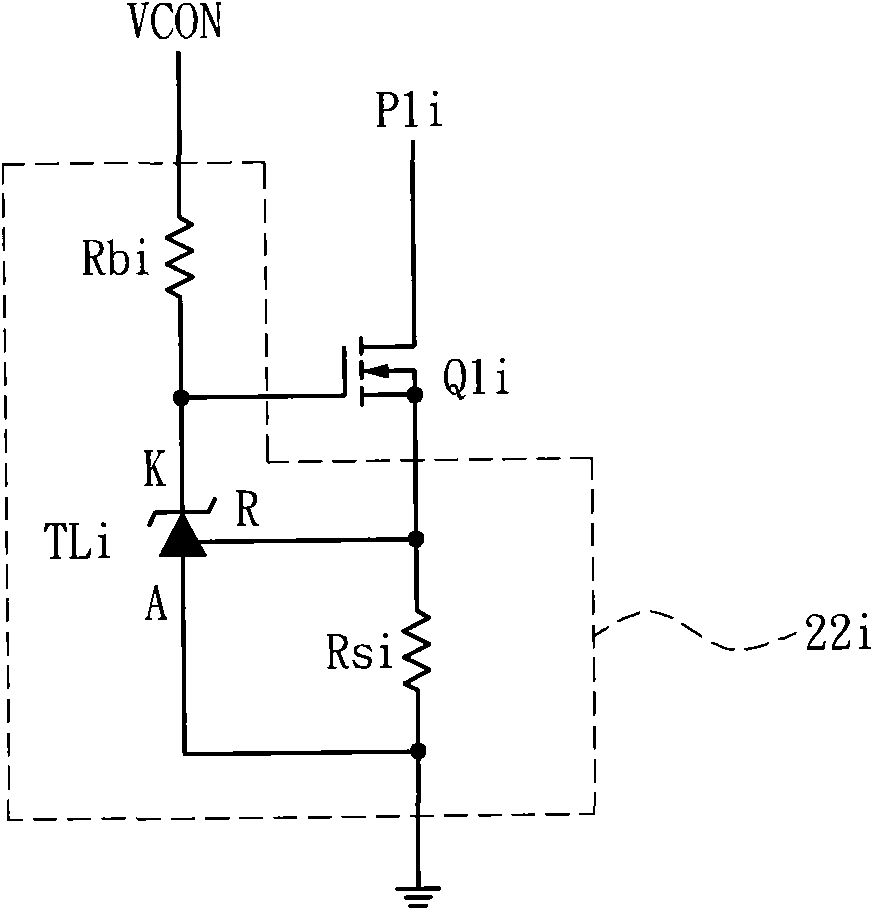

Embodiment Construction

[0020] First of all, it should be noted that those skilled in the art should know that the switch or the switch circuit has a first terminal, a second terminal and a control terminal. The first type switch or switch circuit is turned on when the control terminal receives a high-level signal (that is, the first terminal and the second terminal are connected), and is not turned on when the control terminal receives a low-level signal (that is, the first terminal is connected). And the second terminal is disconnected); the second type switch or switch circuit is turned on when the control terminal receives a low-level signal (that is, the first terminal and the second terminal are connected) and when the control terminal receives a high-level signal No conduction (that is, the first terminal and the second terminal are disconnected). The first type of switch or switch circuit can be implemented with NPN bipolar transistors (or N-channel field effect transistors), the first termina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com