Method for controlling inverter-integrated electric compressor for vehicle air-conditioning system

A technology of electric compressors and vehicle air conditioners, which is applied in the direction of machines/engines, liquid variable displacement machines, pump control, etc., can solve the problems of cooling power drop, increase in overall size and number of components, increase in production and other costs, etc. Achieve the effect of increasing energy consumption efficiency and preventing joint damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

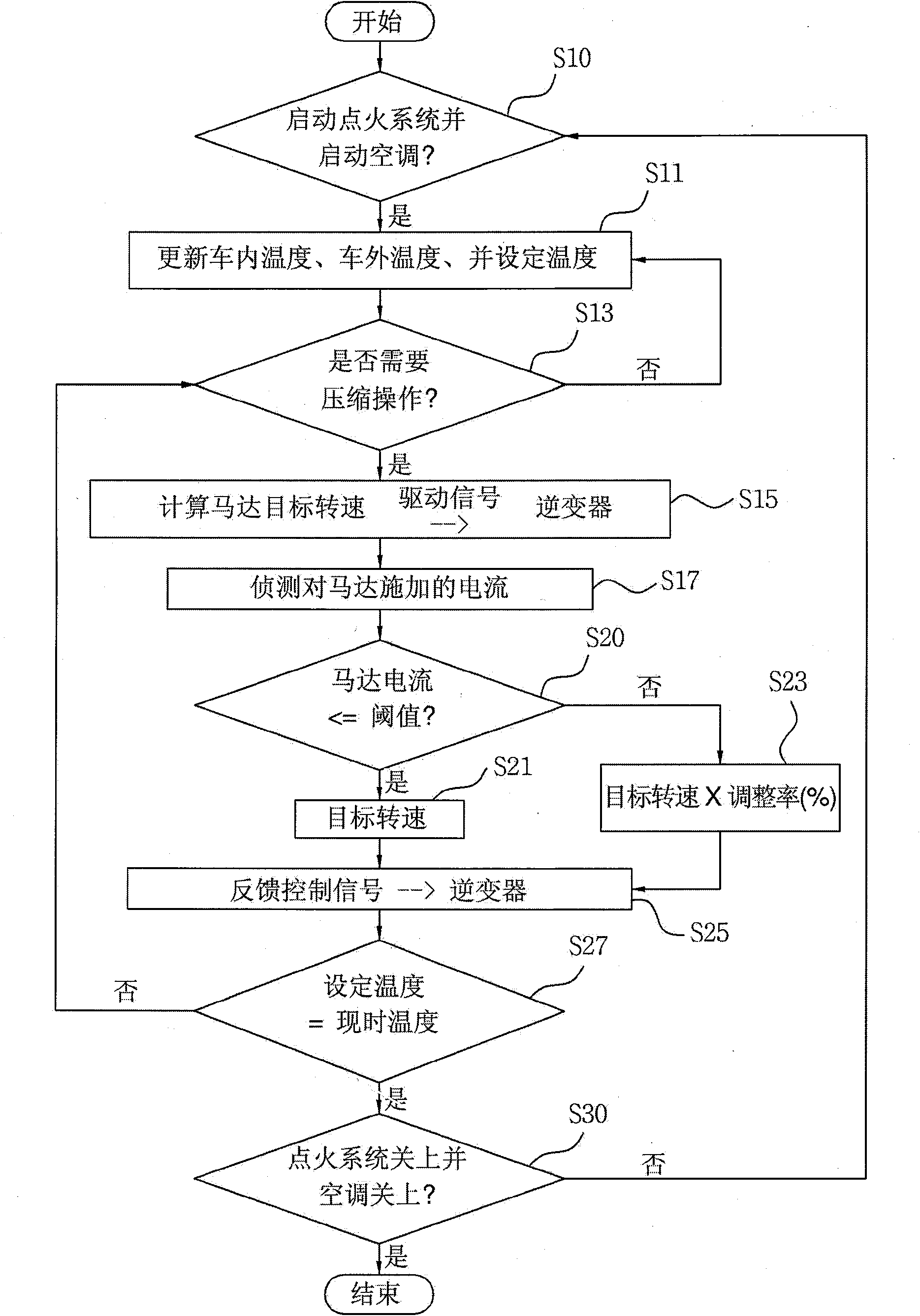

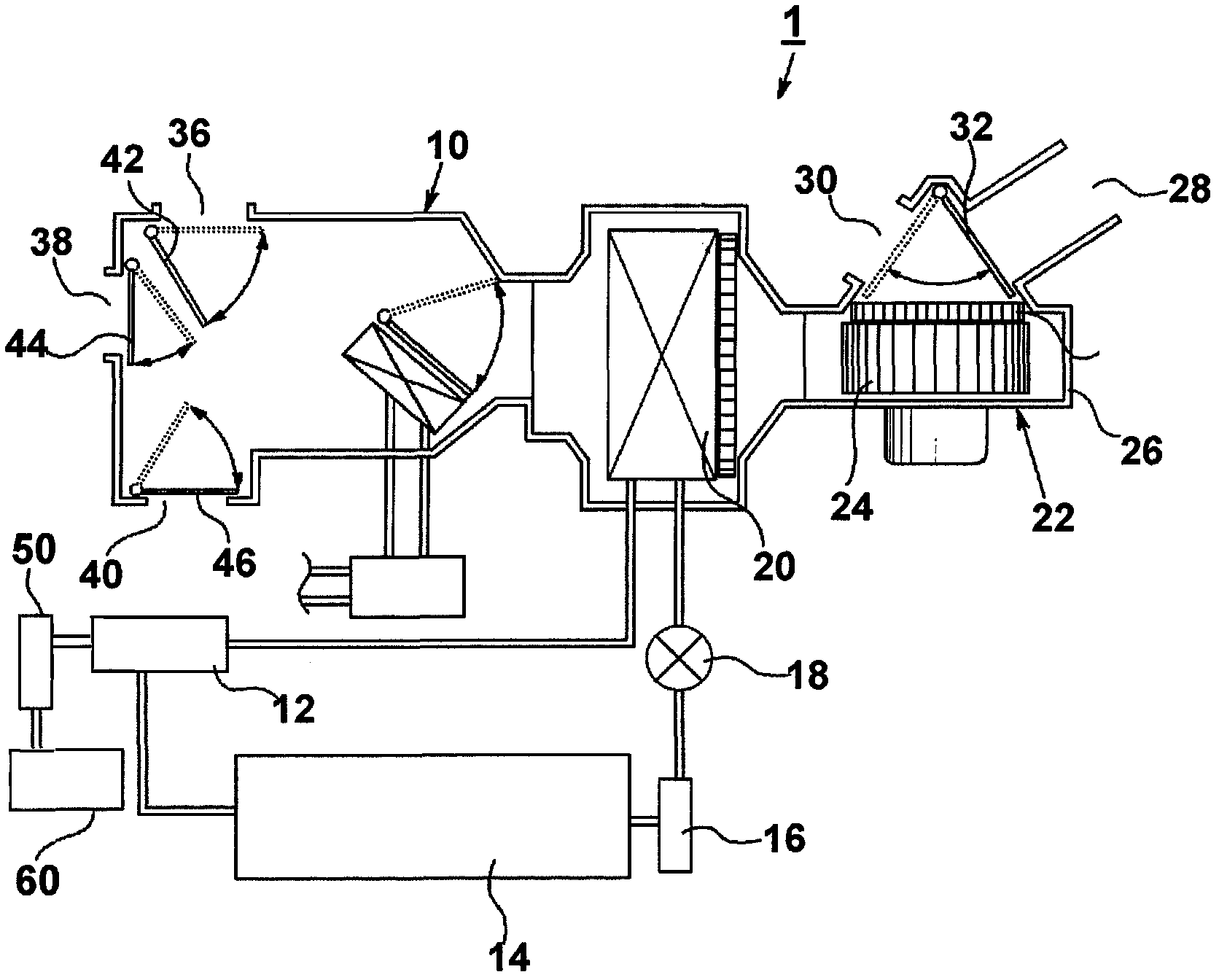

[0026] An embodiment of the present invention will be described in more detail below with reference to the accompanying drawings.

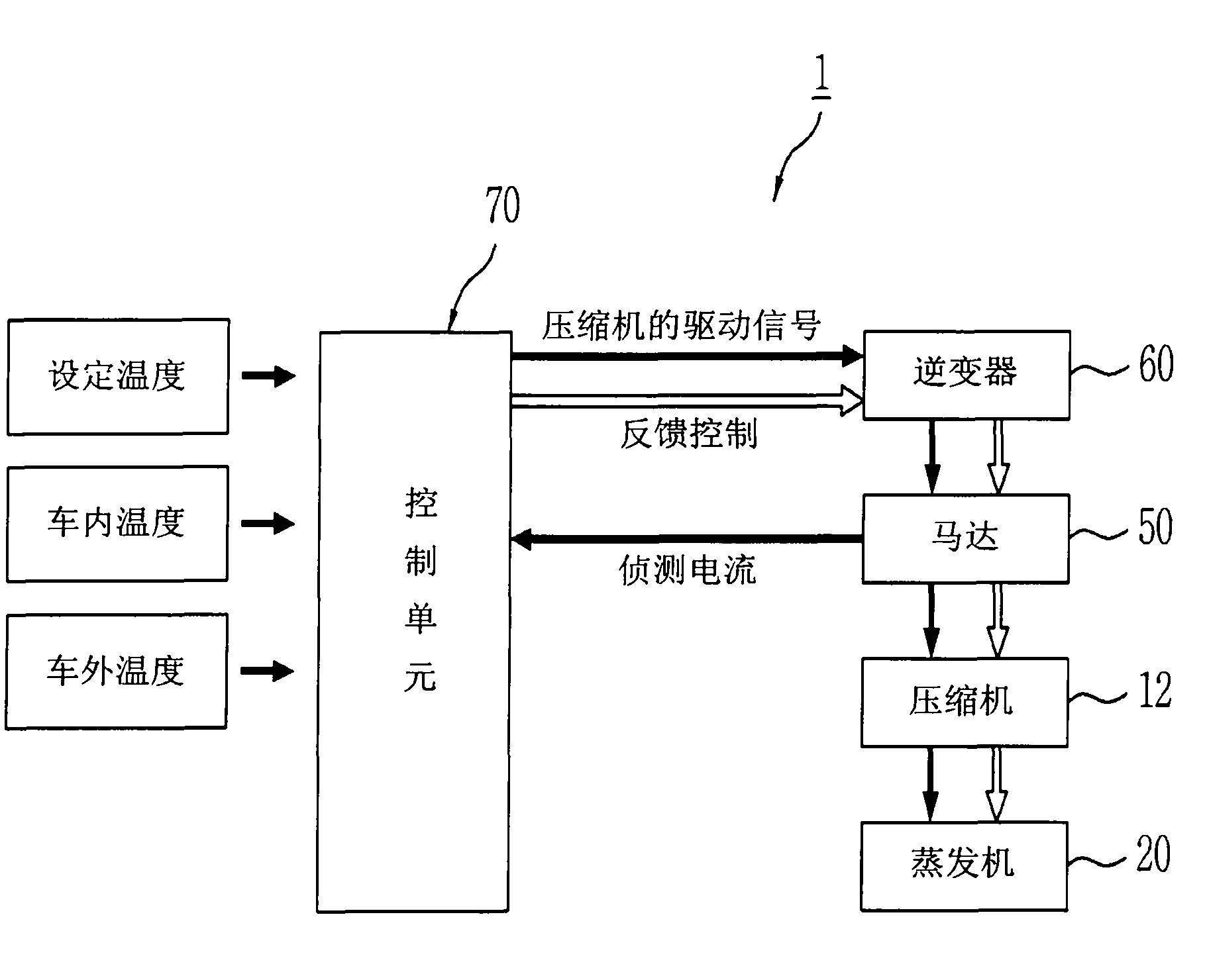

[0027] figure 2 is a block diagram of a vehicle air-conditioning system according to an embodiment of the present invention, and its reference figure 1 illustrate.

[0028] Such as figure 1 and figure 2 As shown, in the vehicle air conditioning system 1 according to the embodiment of the present invention, when the air conditioner of the vehicle is activated and the user inputs the temperature set by the user to the control unit 70, the vehicle temperature measured by the vehicle interior temperature sensor and the vehicle exterior temperature sensor The interior and exterior temperatures are input to the control unit 70 .

[0029] Afterwards, the control unit 70 calculates the difference between the ideal temperature set by the user and the temperature inside the vehicle, and determines whether to drive the electric compressor 12 .

[0030...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com