Powder hot isostatic pressing (HIP) forming method for titanium (Ti) alloy blisk

An integral blade and hot isostatic pressing technology, which is applied in the field of aerospace manufacturing, can solve the problems of integral blade disks that cannot be molded with complex surface structure blades, and achieve excellent mechanical properties, uniform performance, and improved molding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

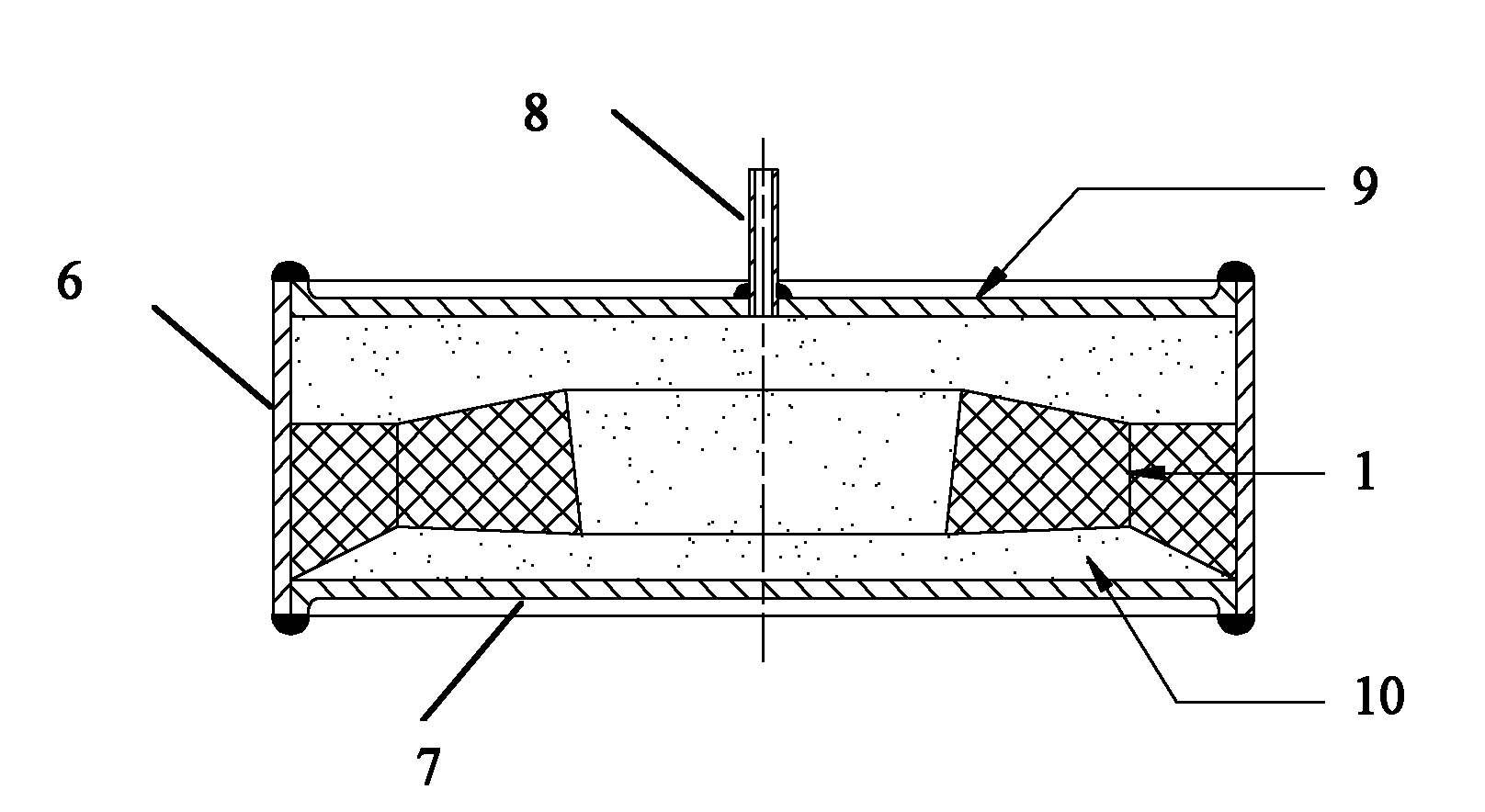

[0025] The powder hot isostatic pressing forming method of the titanium alloy integral blade disk provided by the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

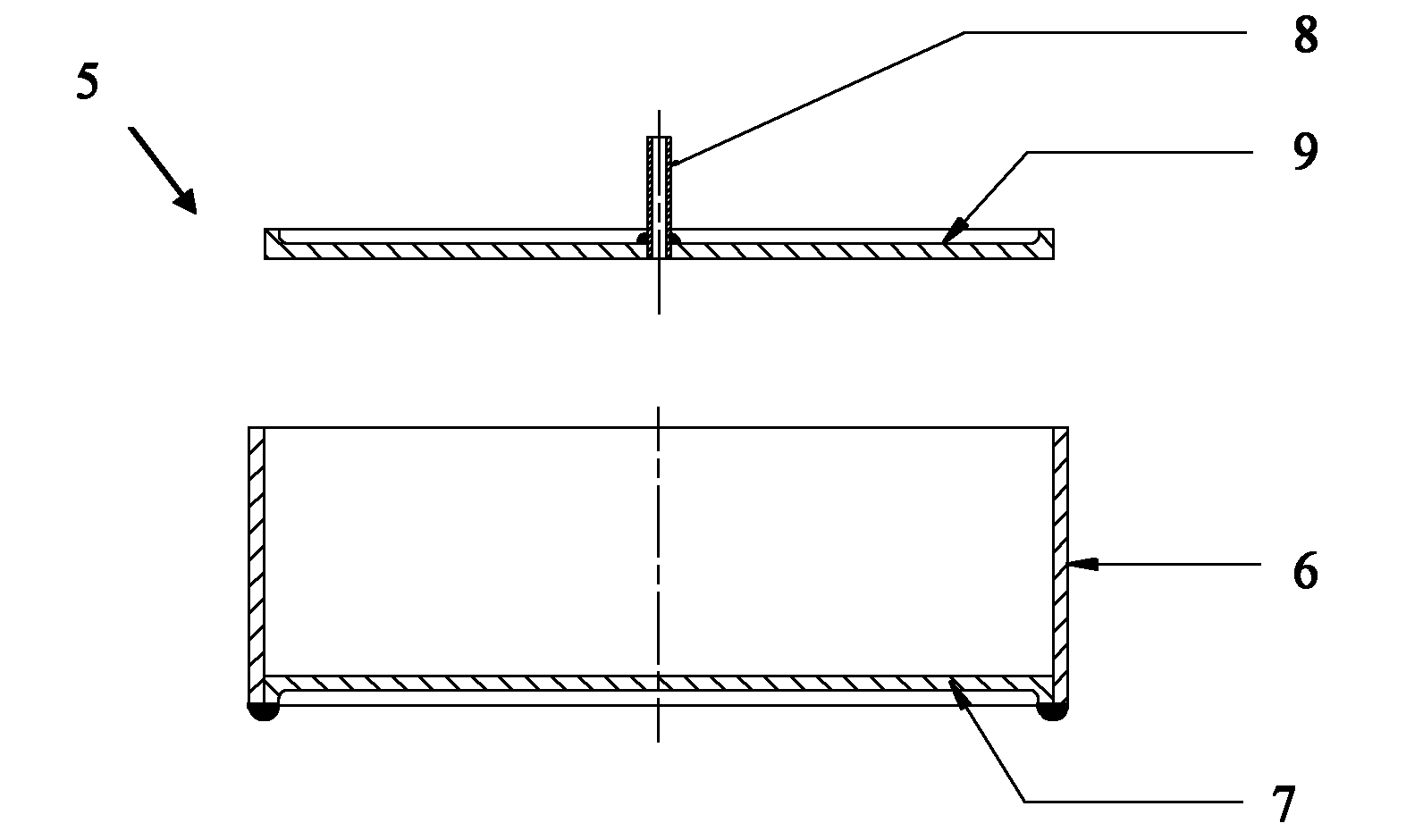

[0026] Such as Figure 1-Figure 5 As shown, the powder hot isostatic pressing method of the titanium alloy integral blade disc provided by the present invention comprises the following steps carried out in order:

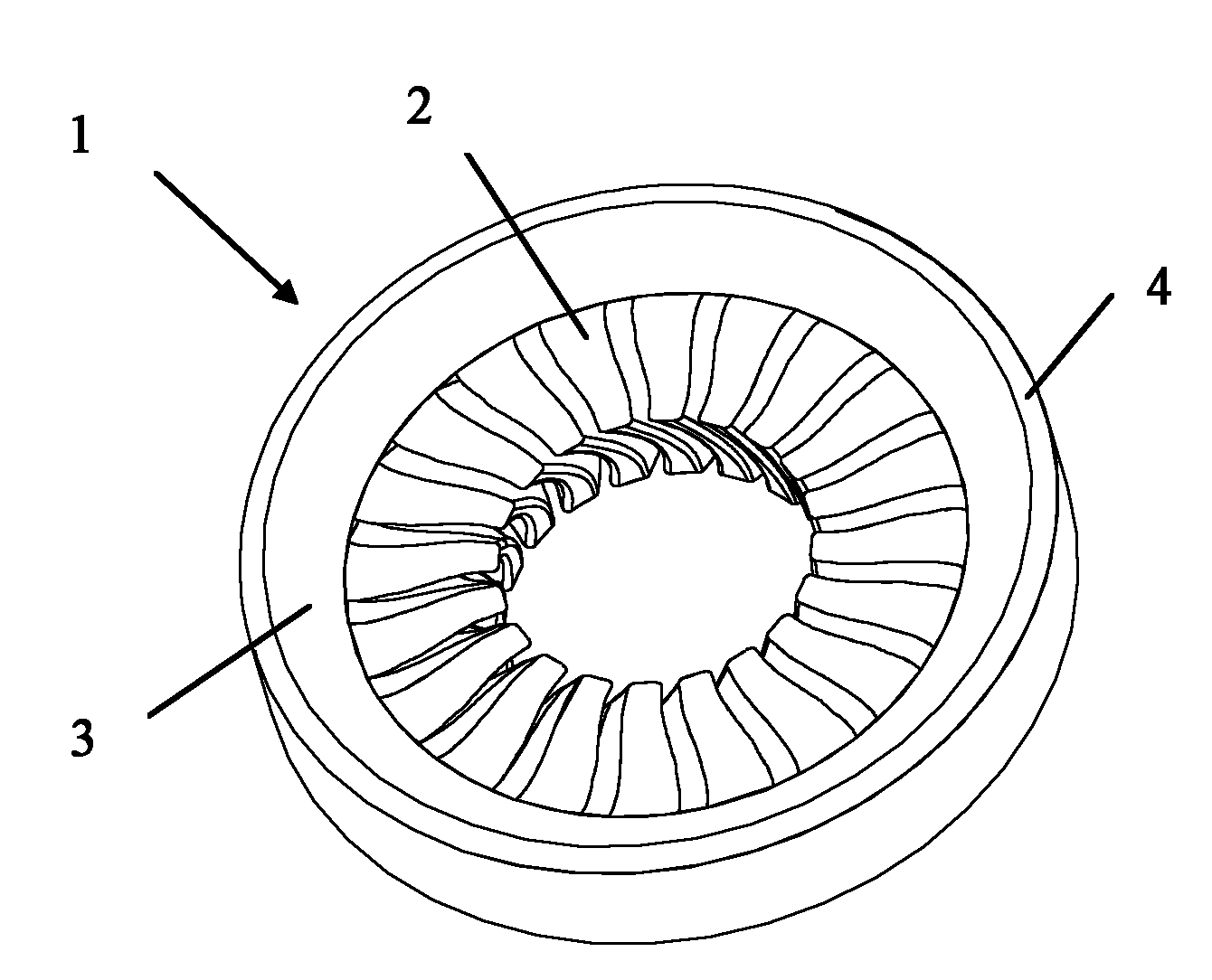

[0027] 1) According to the shape of the whole blade disc 11, such as figure 1 As shown in the mold 1, the mold 1 is composed of a plurality of blade modules 2 arranged in the middle in a ring shape at a distance from each other and a ring 3 connected to the outer ends of the plurality of blade modules 2. At the same time, the outer edge of one side of the ring 3 faces A wedge-shaped protrusion 4 is formed on the outside, and the cavity part in the middle of the mold 1 is in the shape of an integral blisk 11; in addition, the mold 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com