XZC three-axis linkage thread milling method for milling machining center

A machining center, three-axis linkage technology, applied in the field of mechanical processing, can solve the problems of lengthening the production cycle, increasing the repeated positioning error of the screw hole position, and the torque of the accessory spindle not reaching enough large, so as to reduce the number of turnovers and shorten the production. Cycle, reduce the effect of reloading cards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

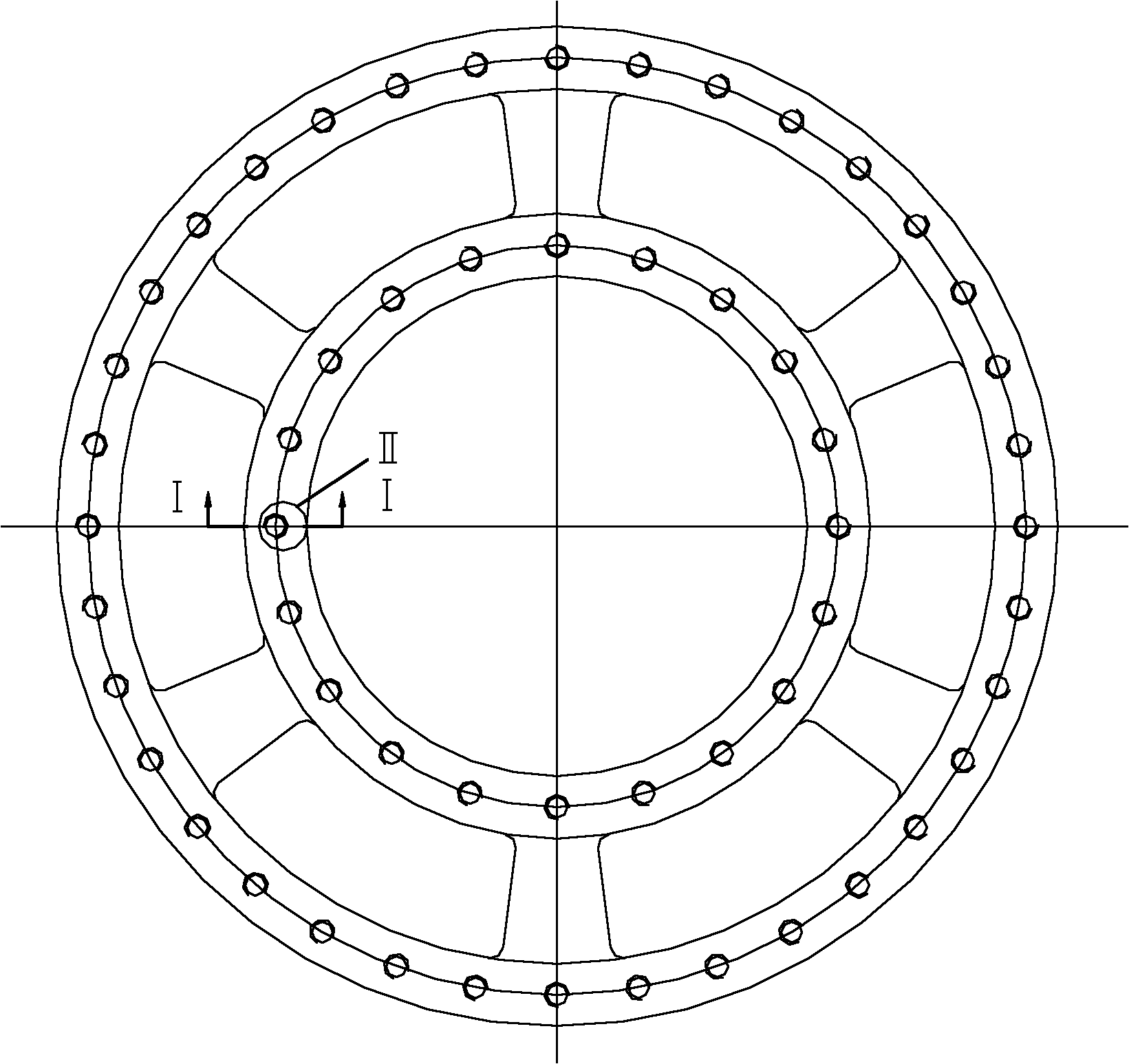

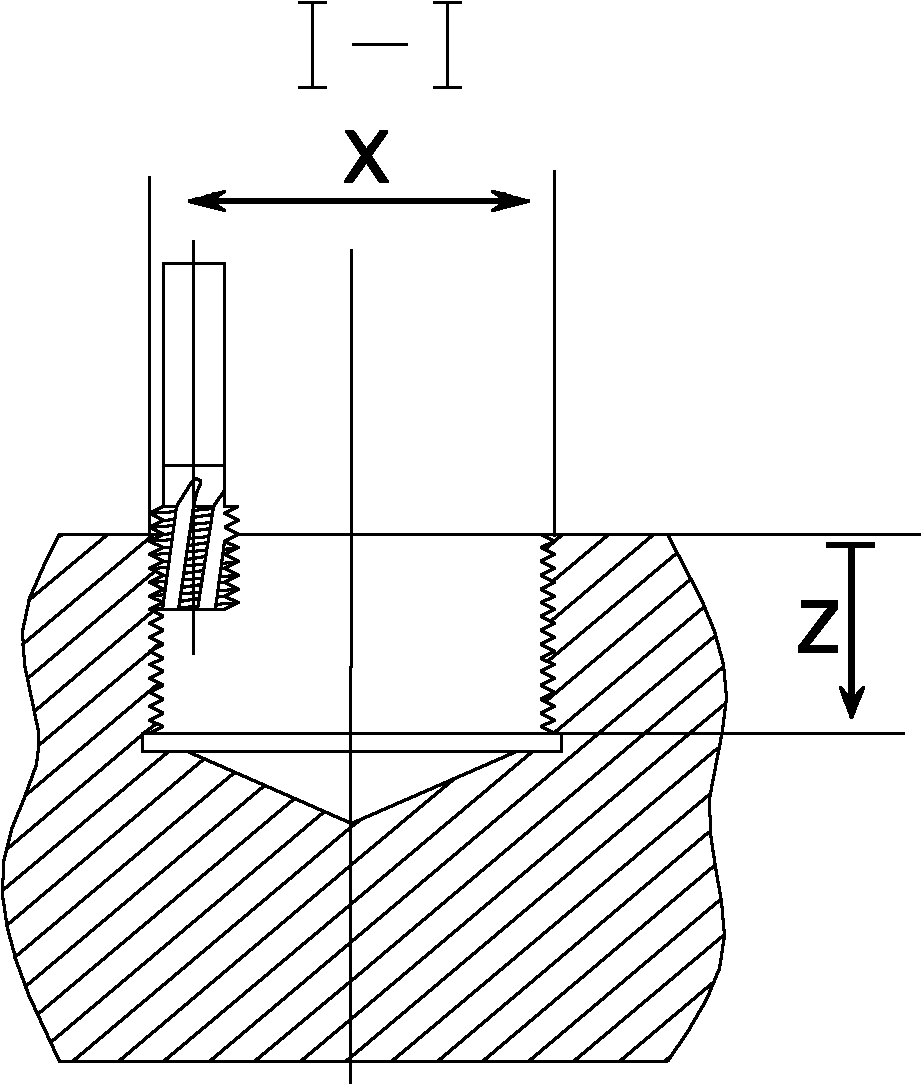

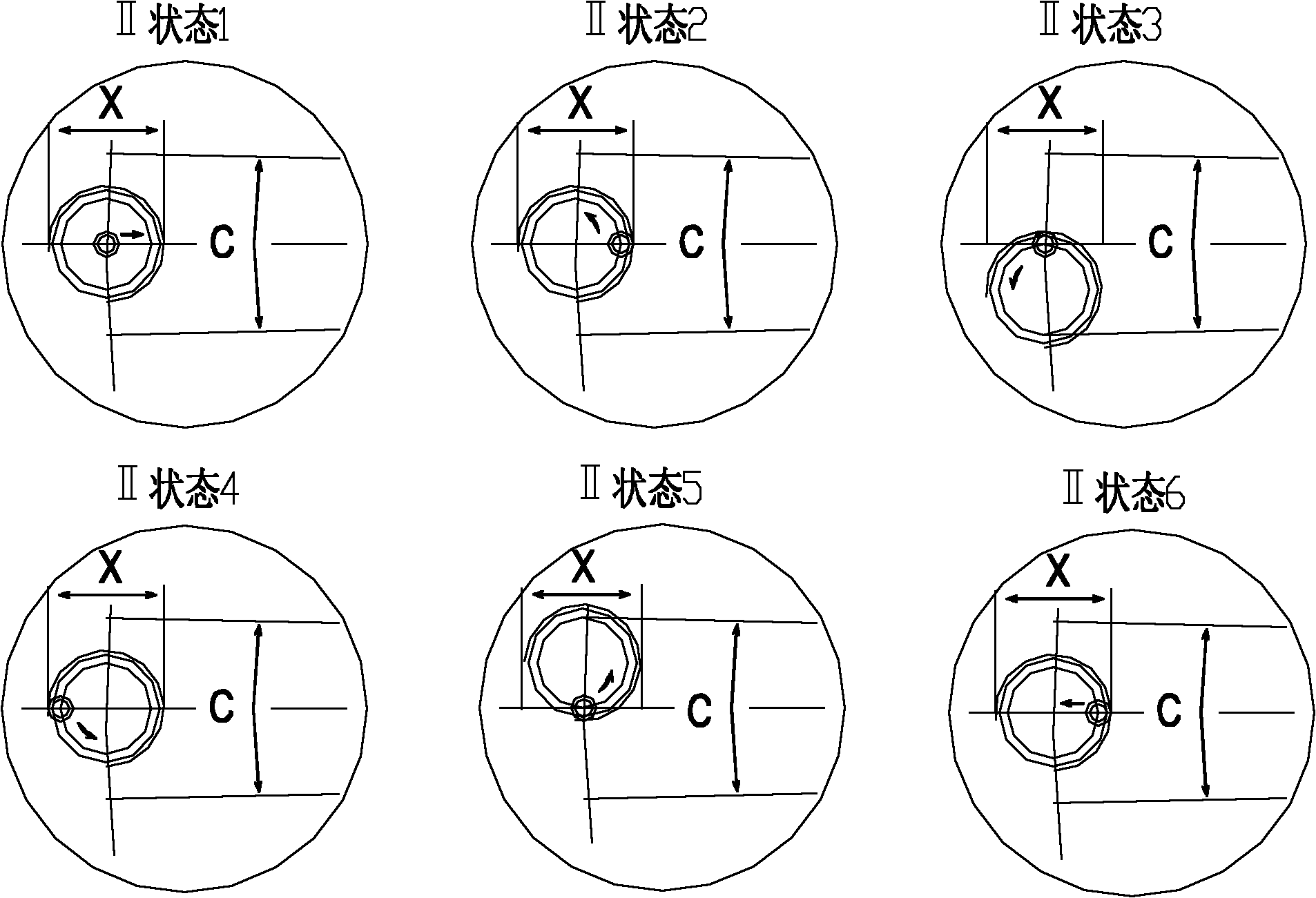

[0030] The following is a large-scale workpiece commonly used in water conservancy and energy machinery by using the CXK5240 vertical turning and milling machining center. The diameter is generally about 3000-8500mm. figure 1 , the end face is evenly distributed with large threaded holes above M42 on the indexing circles of different diameters. Using the above-mentioned XZC three-axis interpolation linkage method, milling completes 20 M100×4 left-handed threads on the index circle of the inner ring. Using CAXA-ME software, the specific processing process is as follows:

[0031] (1) Modeling of parts

[0032] First start the programming software, draw a sketch according to the requirements of the production drawings, or use CAD engineering drawings to import, and then select the solid modeling method, and complete the modeling through operations such as stretching, arraying, and spiral sweeping.

[0033] (2) Initial condition setting

[0034] The initial processing conditions...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com